Light-emitting diodes pack and its packing method

A technology of light-emitting diodes and packaging methods, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of color spots, efficiency reduction, and efficiency reduction, and achieve easy dispersion, high brightness, and high efficiency. White light, luminous color uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the light emitting diode package and its packaging method of the present invention will be described in detail below with reference to the accompanying drawings.

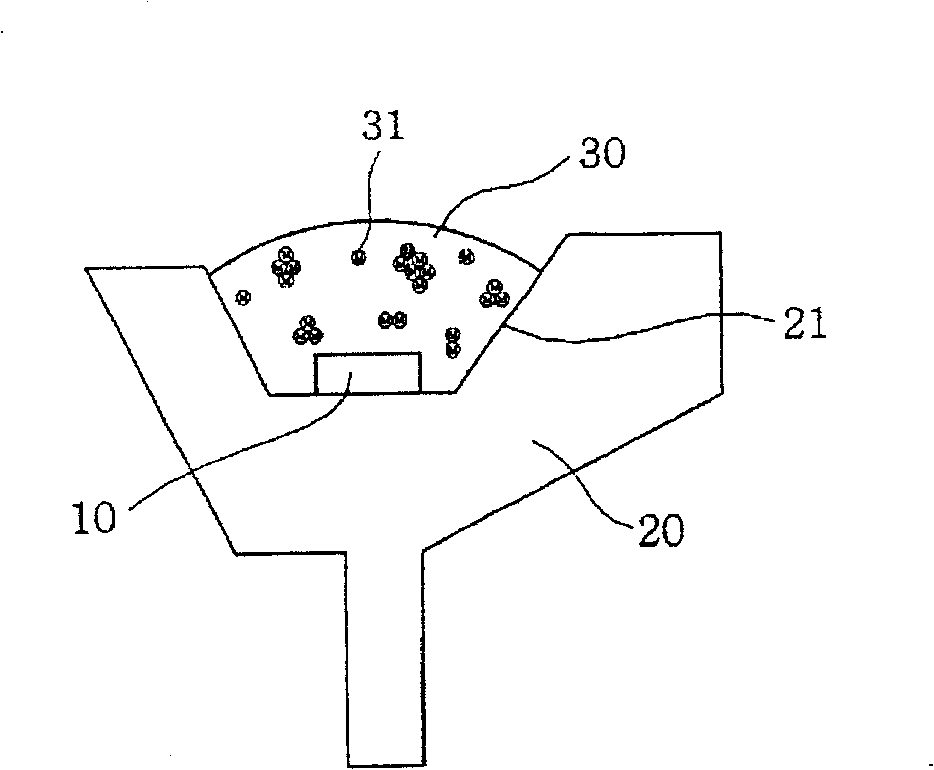

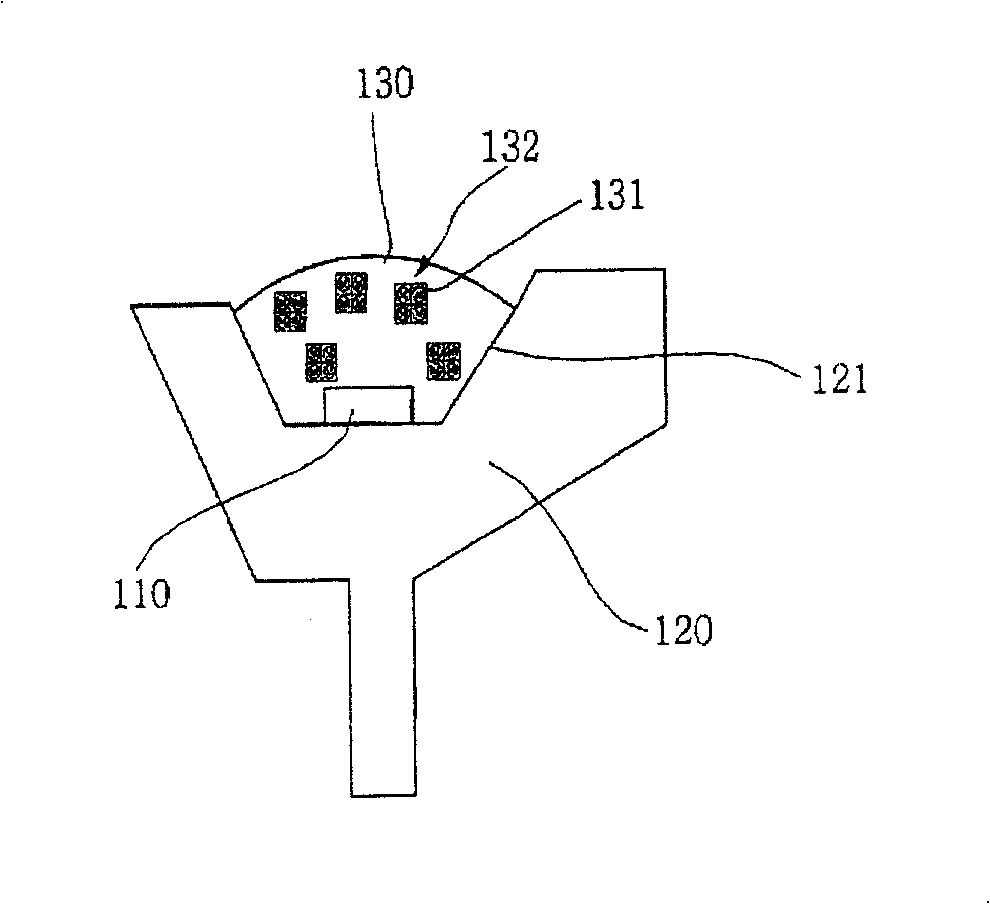

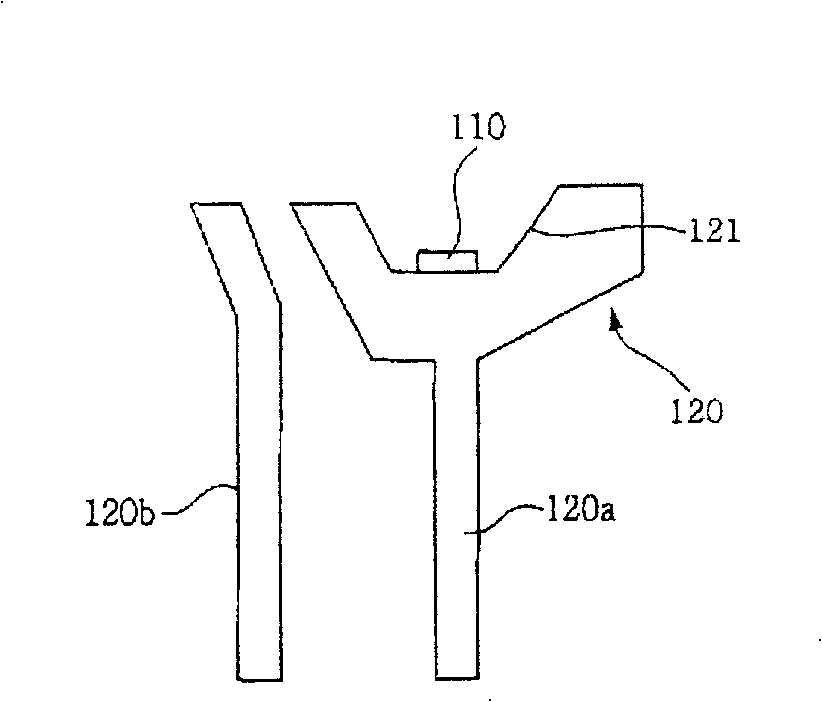

[0047] figure 2 It is a schematic structural view of the state in which the polymer resin in which the organic and inorganic mixed phosphor particles containing organic phosphor molecules are dispersed in the porous inorganic chemical particle of the present invention is sprayed in the light-emitting diode, and the protection is connected to the The light-emitting diodes 110 in the cup-shaped reflector of the lead frame 120, the porous interior of the porous inorganic chemical particles, the organic and inorganic mixed phosphor particles 132 containing organic phosphor molecules 131 are dispersed, and the polymer resin 130 is sprayed. .

[0048] The organic-inorganic mixed phosphor particle 132 is defined as follows: organic phosphor molecules 131 are included in the pores of the porous inorg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com