Inhibitor for controlling carbon dioxide corrosion and production thereof

A technology of carbon dioxide and corrosion inhibitors, which is applied in the field of corrosion inhibitors for controlling carbon dioxide corrosion and its preparation, and can solve problems such as poor corrosion inhibitor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

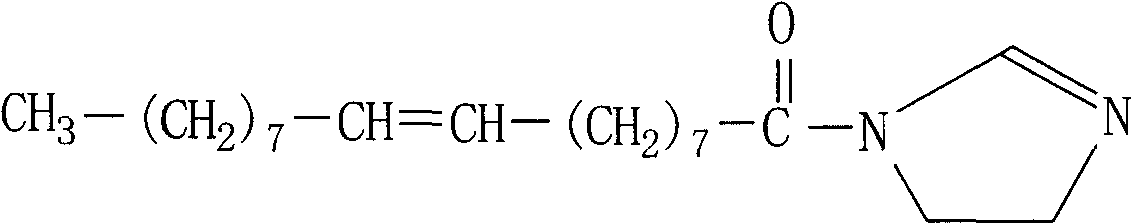

[0020] The preparation method of the corrosion inhibitor provided by the invention comprises contacting and reacting oleic acid and diethylenetriamine to obtain oleic acid imidazoline; uniformly mixing the oleic acid imidazoline with other components of the corrosion inhibitor.

[0021] The preparation process of the oleic acid imidazoline includes putting oleic acid into a reaction vessel, adding diethylenetriamine under the condition of reflux condensation and stirring, then reacting at 100-150° C. for 2-6 hours, and then reacting at 180-180° C. React at 250°C for 2-6 hours, and finally lower the temperature to 80-100°C to obtain oleic acid imidazoline. Reflux condensation and stirring are required during the reaction. The weight ratio of the amount of oleic acid and diethylenetriamine is 1-5, preferably 1.5-3.

[0022] Add thiourea and isopropanol into water at 40-80°C, and after they are completely dissolved, add polyoxyethylene ether and mix evenly, then add imidazoline o...

Embodiment 1

[0025] This example is used to prepare corrosive media.

[0026] Add 120 grams of sodium chloride into 3880 grams of water, stir to completely dissolve the sodium chloride, and obtain a 3.0% by weight sodium chloride solution as a corrosion medium.

Embodiment 2

[0028] This embodiment is used for preparing imidazoline oleate.

[0029] 50 grams of oleic acid was put into a 500 ml reaction kettle, and 20 grams of diethylenetriamine was slowly added under the conditions of reflux condensation and stirring. Then, the power was turned on, the oil bath was heated, and the reaction was carried out at 110° C. for 3 hours, and then at 200° C. for 5 hours. After that, the heating was stopped, and the temperature was lowered to 90° C. to obtain imidazoline oleate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com