Stabilivolt type pressure reducer

A pressure-reducing valve and voltage-stabilizing technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of hydrogen leakage, hydrogen leakage, explosion, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

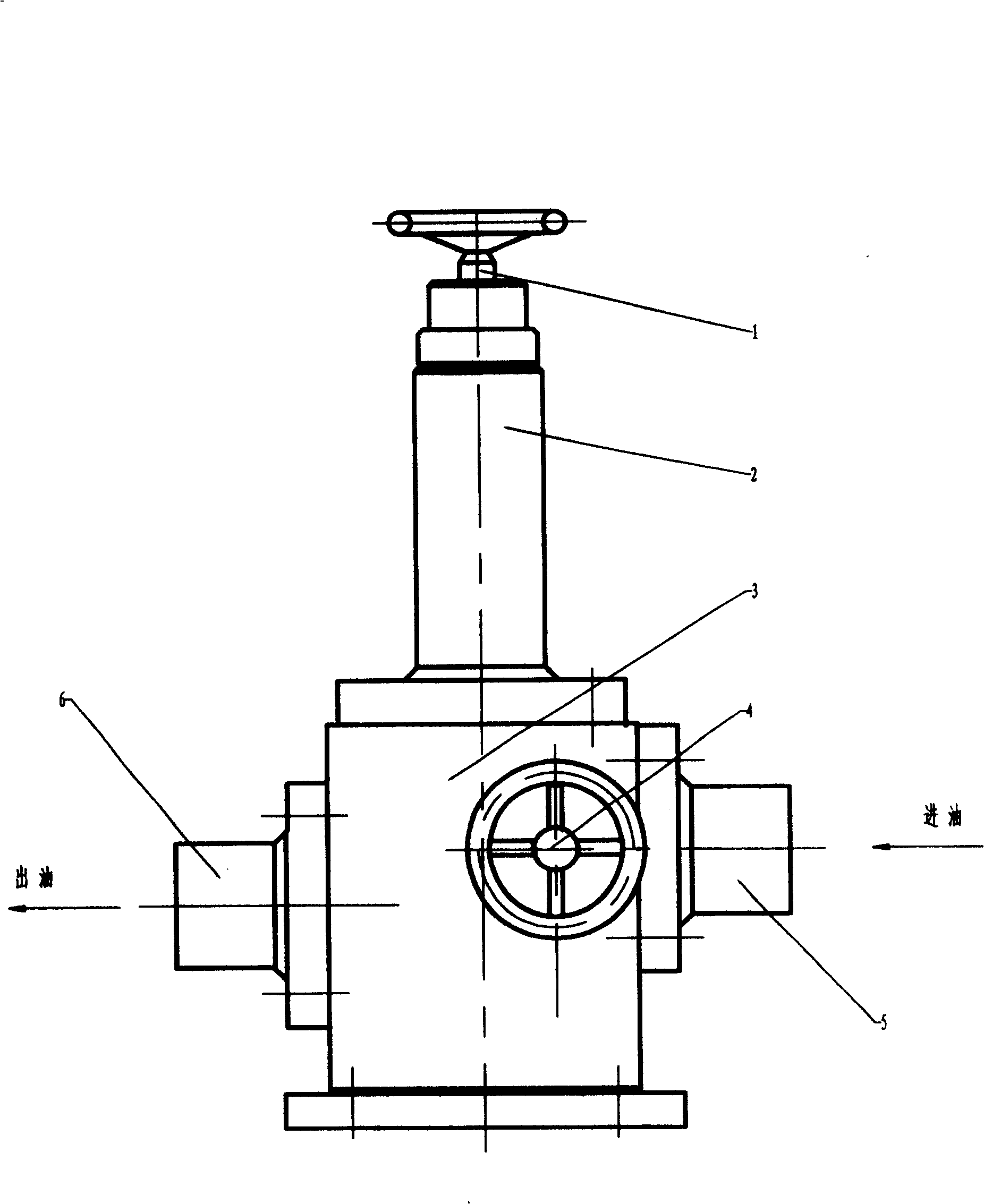

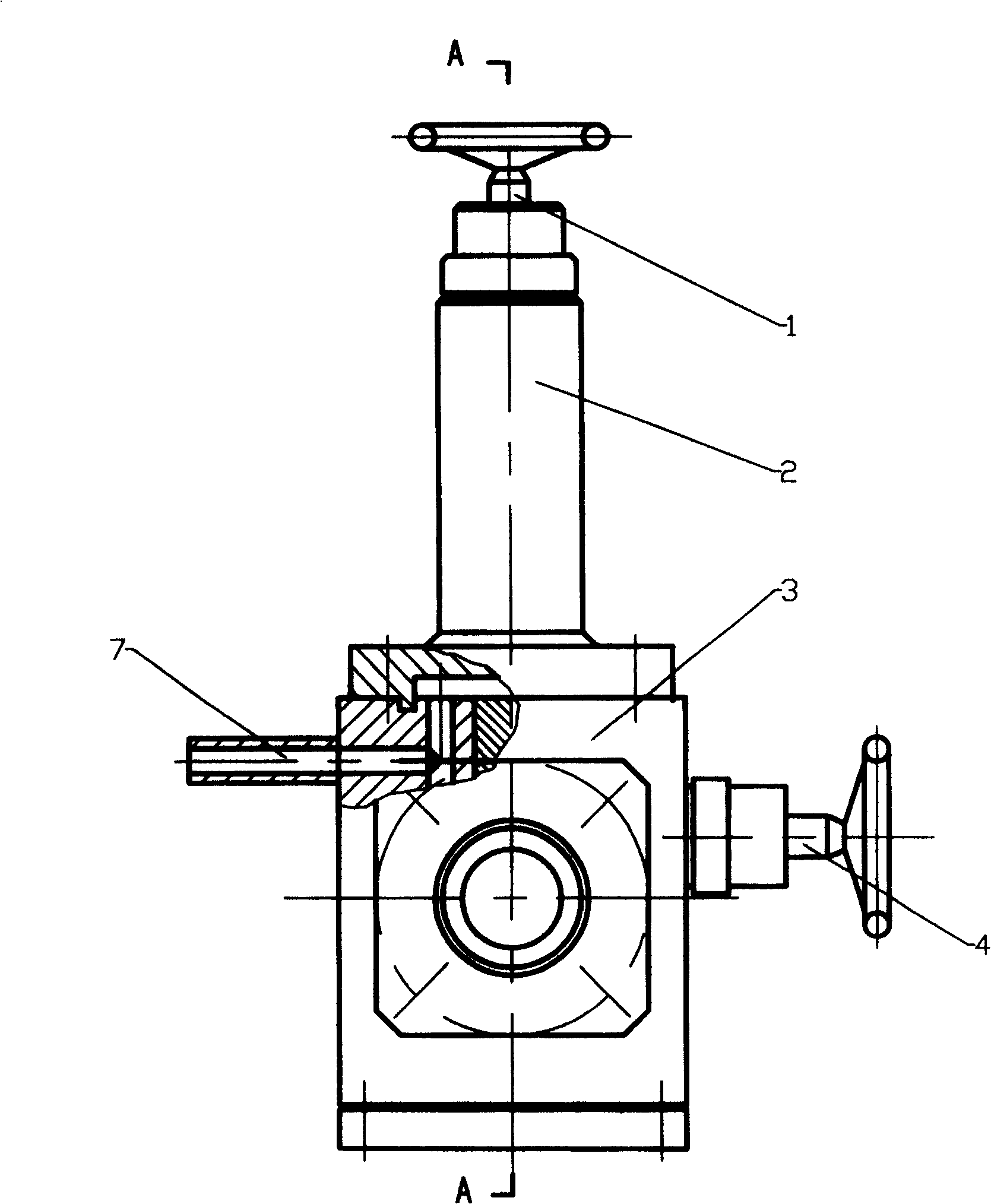

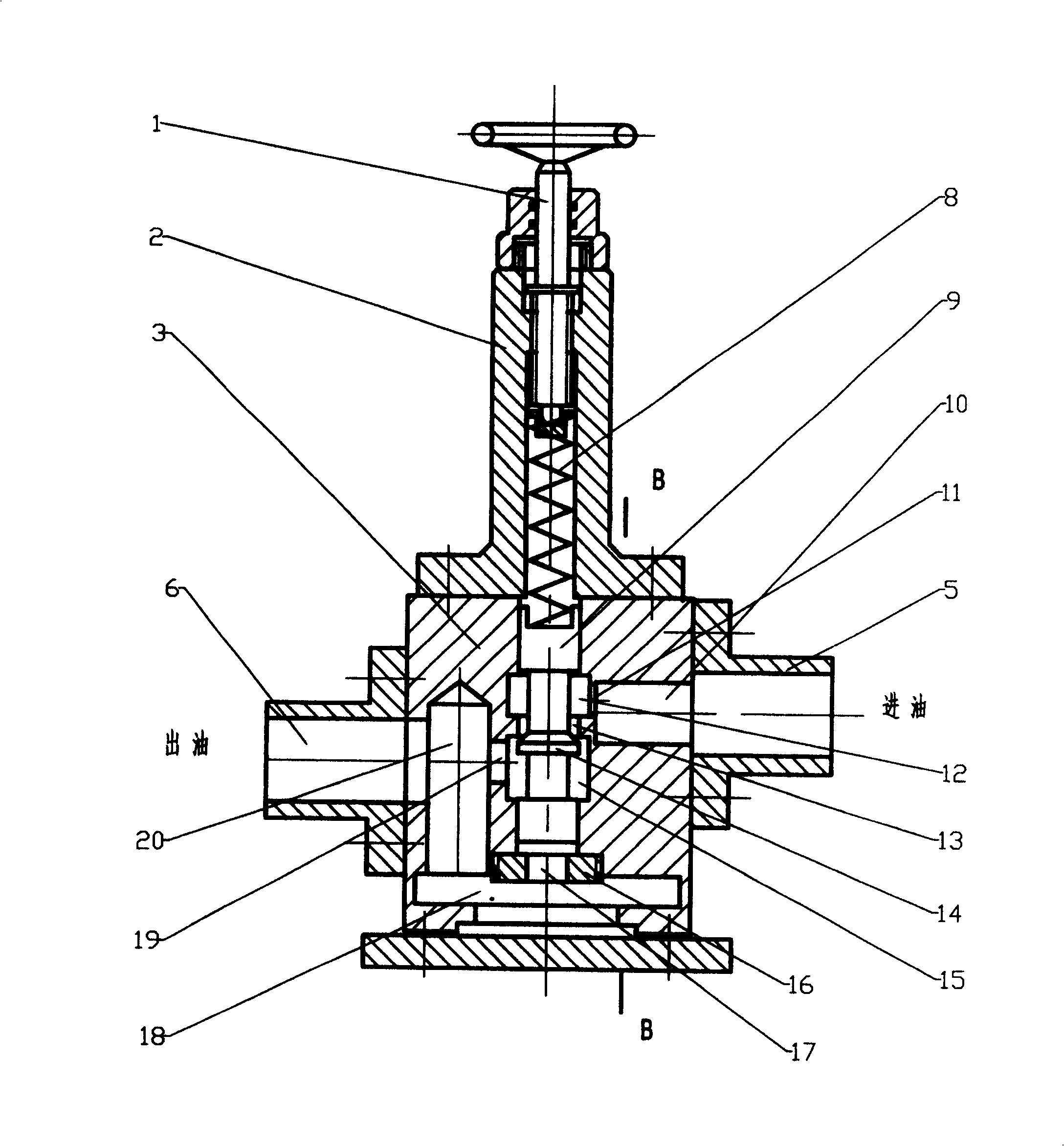

[0012] Such as Figure 1-4 The pressure-stabilizing pressure reducing valve shown is composed of automatic pressure-stabilizing adjusting rod 1, bonnet 2, valve body 3, manual regulating valve 4, spring 8, valve core 9 and other main components, among which the inner hole configuration of bonnet 2 is designed Spring 8 (as attached image 3 shown), and is adjusted by the automatic pressure-stabilizing adjustment lever 1, the spring is placed on the upper part of the valve core 9, and the conical boss on the valve core forms a cone door 14 to cooperate with the door seat hole 13 of the valve body, and the valve body A bottom plug 16 is arranged at the lower end, and a small hole 17 is arranged on the bottom plug 16 . The interaction between the pressure of the spring on the upper part of the spool and the oil pressure on the lower part of the spool controls the opening of the cone door 14 of the spool to automatically adjust the oil pressure. The valve body 3 is also provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com