Solid polymer electrolyte fuel cell assembly, fuel cell stank, and method of supplying reaction gas ni fuel cell

A solid polymer, fuel cell technology, applied in solid electrolyte fuel cells, fuel cell grouping, fuel cell components, etc., can solve problems such as increasing the number of single cells, inability to ensure power generation performance, and deterioration of temperature distribution and discharge characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

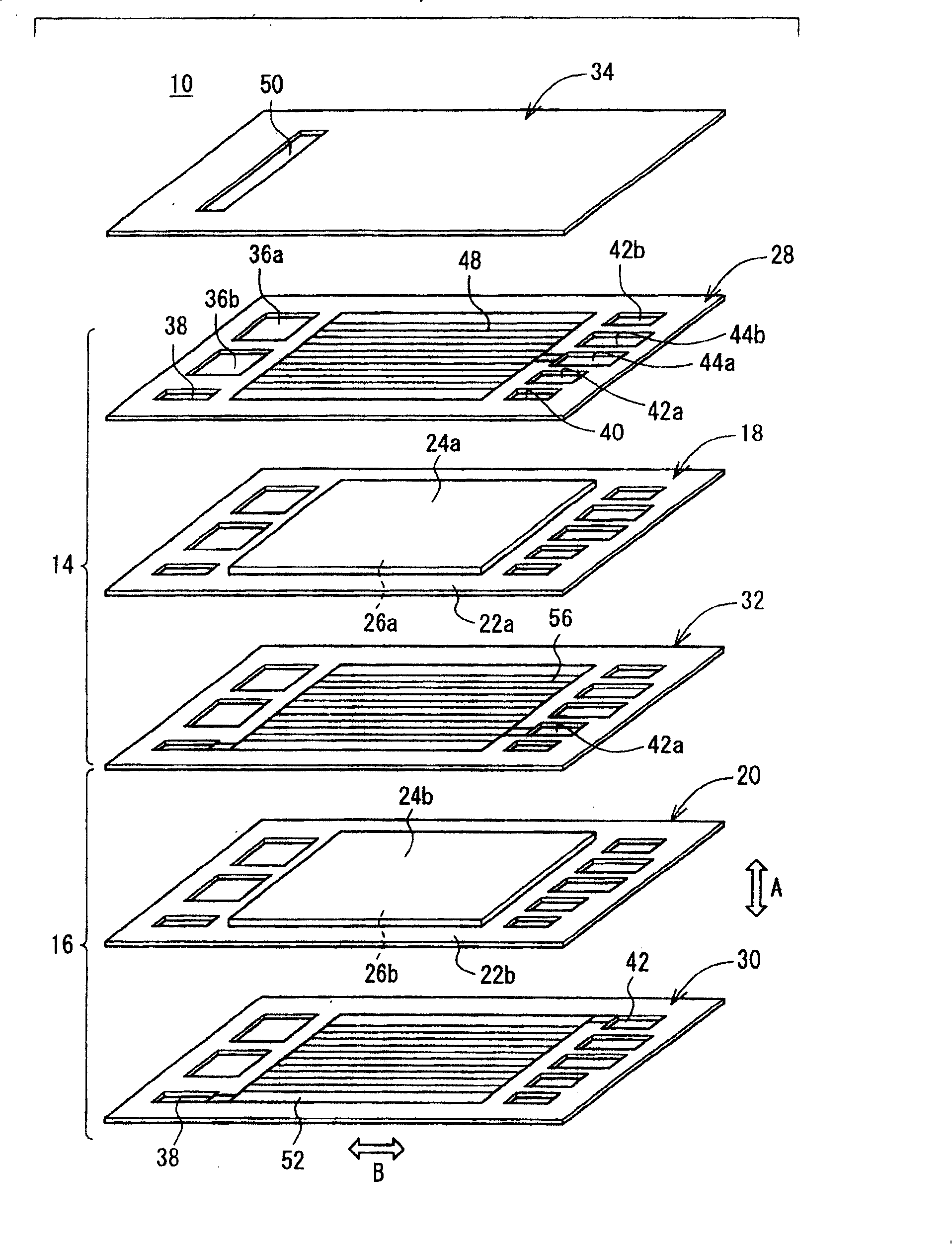

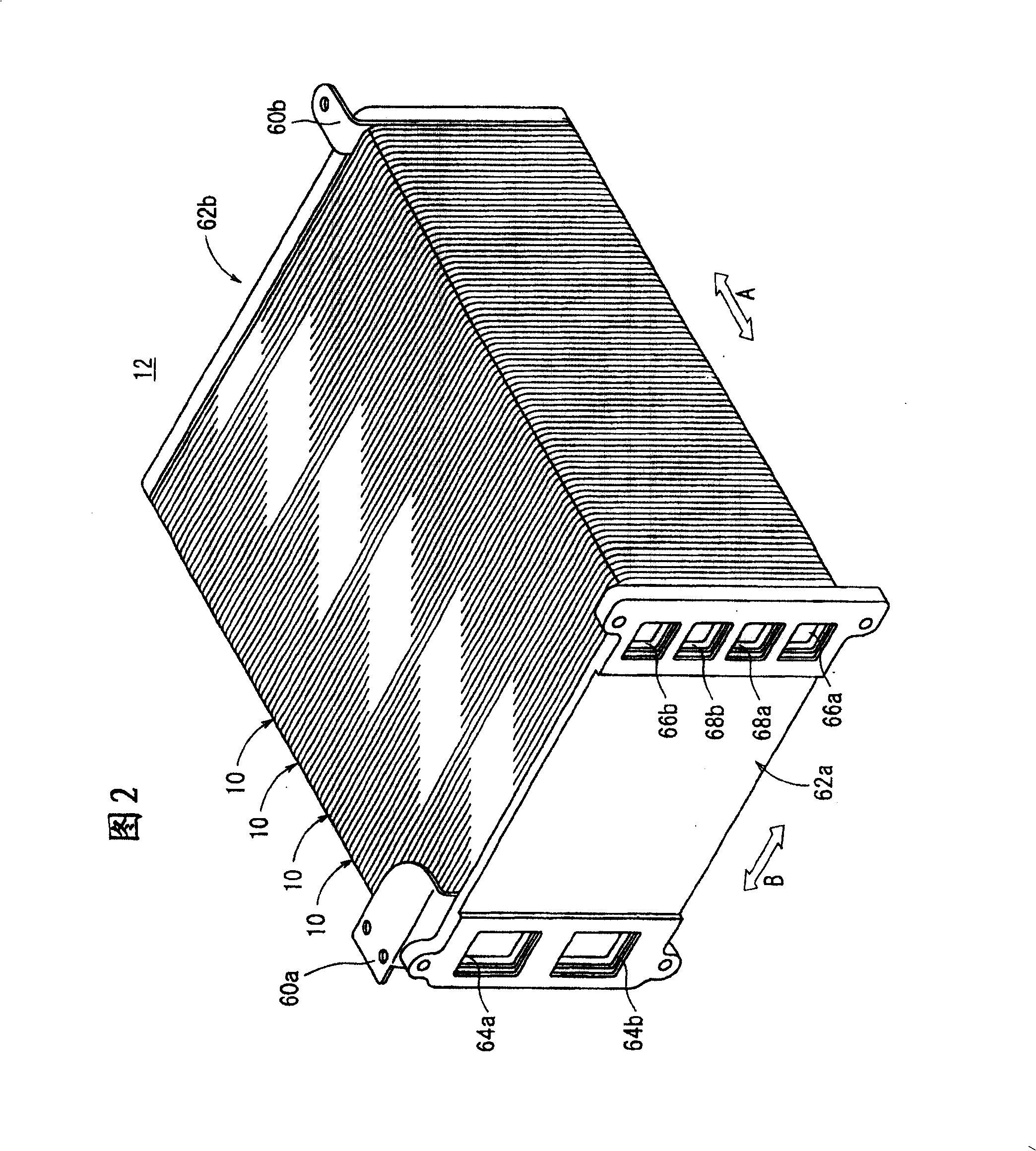

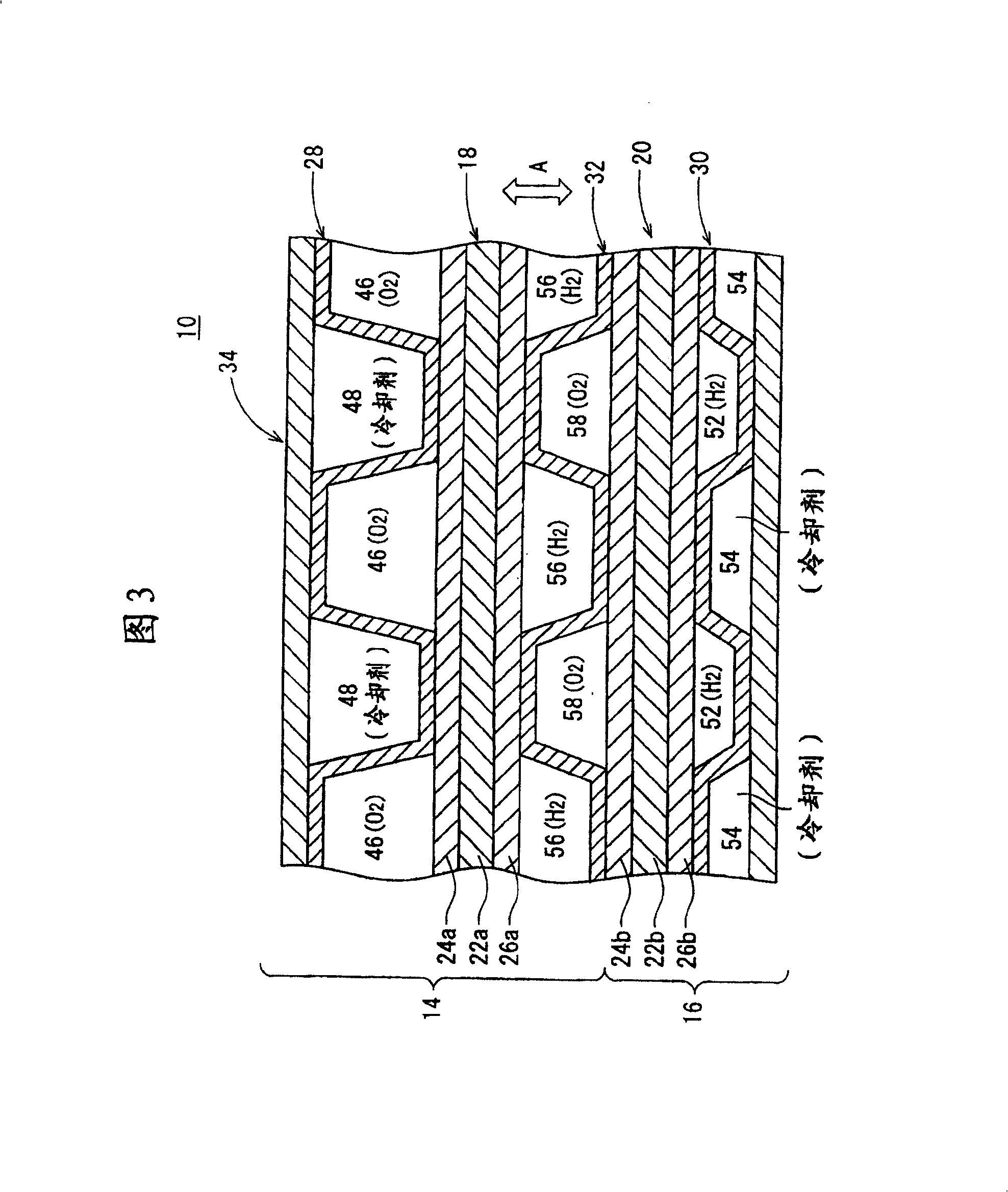

[0099]According to the first embodiment, the battery assembly 10 is constituted as an integral body of the first and second unit cells 14 and 16, and in addition, at least part of the oxidizing gas passage 46 provided in the first unit cell 14 is connected in series through the oxidizing gas intermediate connection hole 40 to at least part of the oxidizing gas channel 58 provided in the second unit cell 16; and at least part of the fuel gas channel 56 provided in the first unit cell 14 is connected in series to the channel 58 provided in the second unit cell 16 through the fuel gas intermediate connection hole 38 At least part of the fuel gas passage 52 in. Therefore, the oxidizing gas of the flow required for the entire reaction in the first and second unit cells 14 and 16 is supplied to the oxidizing gas passage 46 on the inlet side; A fuel gas at a flow rate necessary for the reaction is supplied to the fuel gas passage 56 on the inlet side. In other words, the oxidizing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com