Operation control method for linear compressor

A linear compressor and operation control technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve problems such as lack of connecting rods, unstable pressure, etc., to reduce energy consumption, increase down rate, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Figure 3a It is a flow chart of Embodiment 1 of the operation control method of the linear compressor of the present invention.

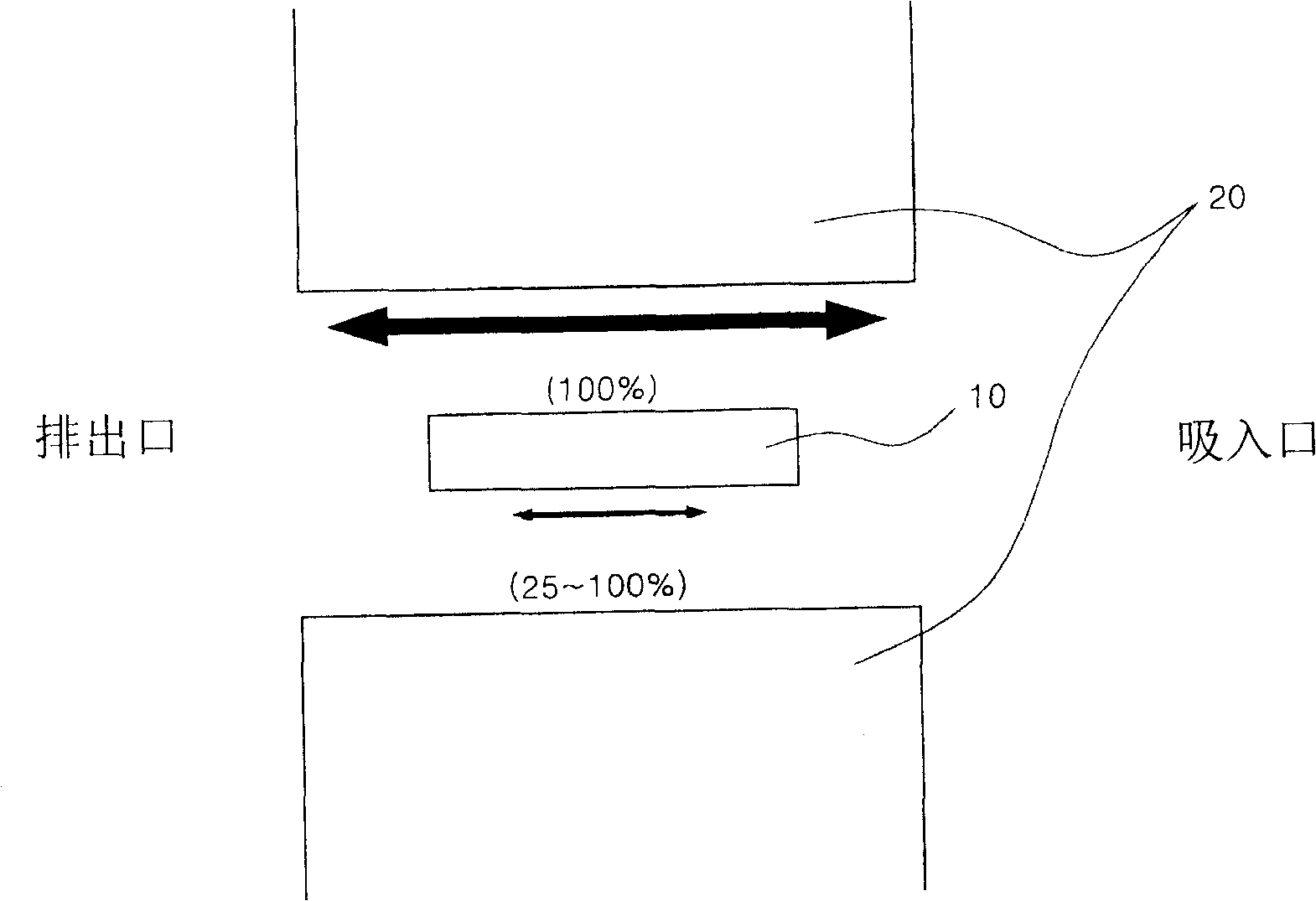

[0038] After the linear compressor is energized and started, the piston (10) inside the compressor starts to reciprocate. In the present invention, by setting the elapsed time of the pressure-holding stroke cycle and the full stroke cycle and the reciprocating range value of the piston (10), The piston (10) is driven and controlled to perform reciprocating motion within a set range.

[0039] Specifically, as Figure 3a As shown, the operation control method of the linear compressor of the present invention includes:

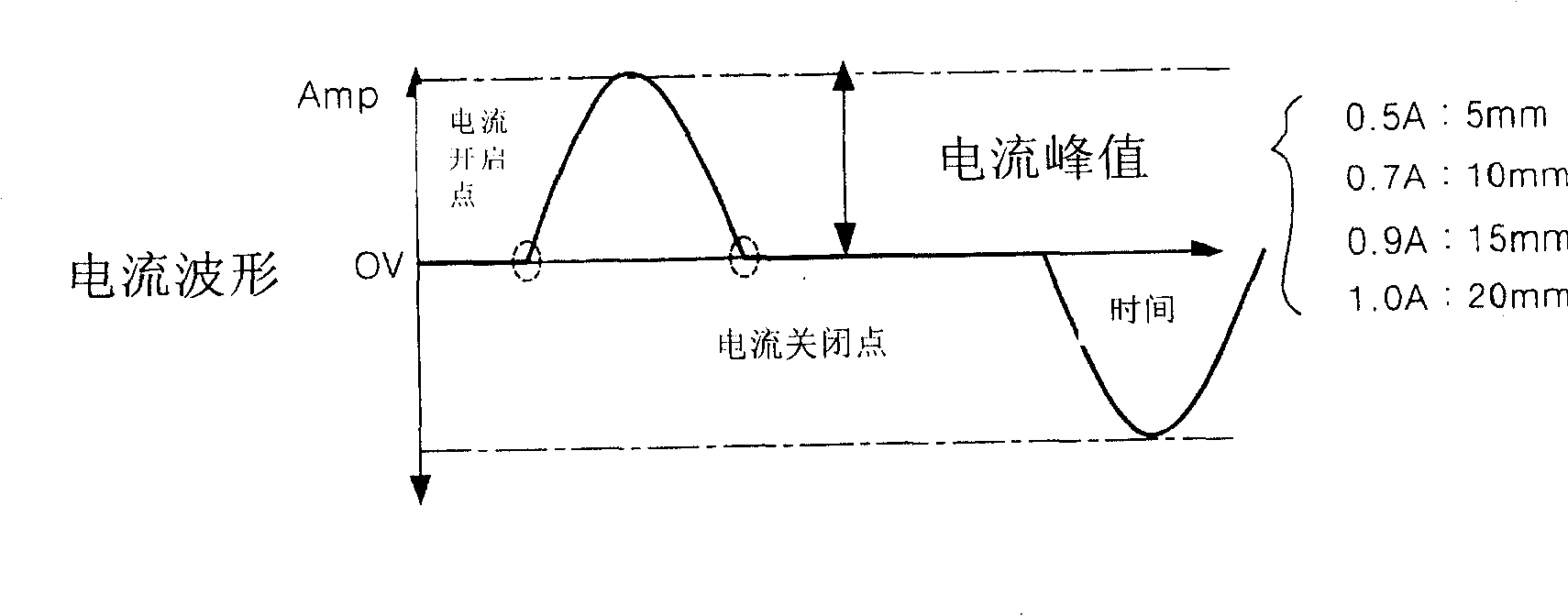

[0040] The 100th stage: the input power makes the piston (10) start to reciprocate. At this time, in order to judge whether the piston (10) is driven within the set range of the full stroke, the input compression is sensed during the reciprocating motion of the piston during the pressure-holding stroke cycle. The current val...

Embodiment 2

[0047] Figure 3b It is a flow chart of Embodiment 2 of the operation control method of the linear compressor of the present invention; Embodiment 2 is described in detail below:

[0048] After the linear compressor is energized and started, the piston (10) inside the compressor starts to reciprocate. In the present invention, by setting the elapsed time of the pressure-holding stroke cycle and the full stroke cycle and the reciprocating range value of the piston (10), The piston (10) is driven and controlled to perform reciprocating motion within a set range.

[0049] Specifically, as Figure 3b As shown, the operation control method of the linear compressor of the present invention includes:

[0050] The 200th stage: input power to make the piston (10) start reciprocating;

[0051] The 210th stage: the reciprocating motion of the piston (10) will reach the full stroke cycle after the specified time;

[0052] Stage 220: If the time from the start of the reciprocating motion...

Embodiment 3

[0057] Fig. 3c is a flow chart of Embodiment 3 of the operation control method of the linear compressor of the present invention.

[0058] As shown in Figure 3, the operation control method of the linear compressor of the present invention includes:

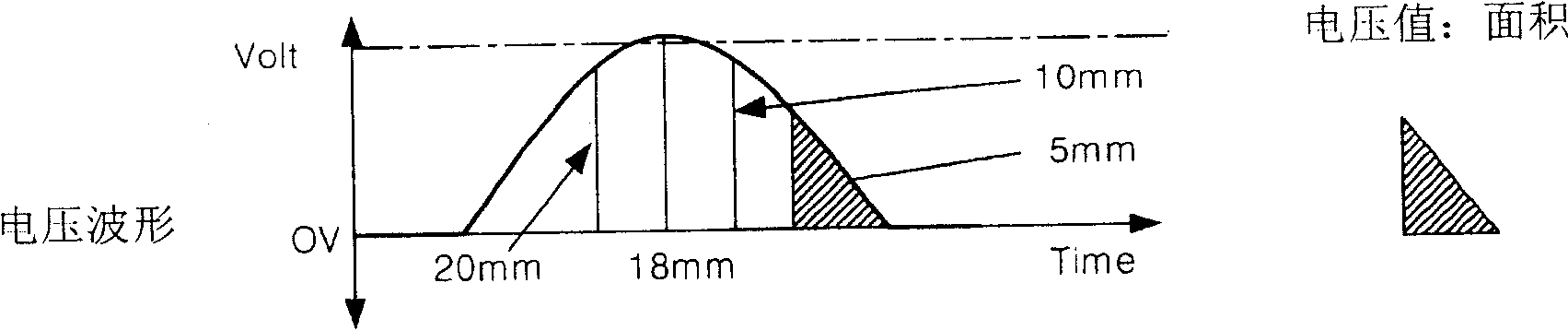

[0059] Stage 300: After the power is input, the piston (10) starts to reciprocate. At this time, the control unit (not shown in the figure) presets the current value and stroke input to the compressor when the piston (10) reaches the starting point of the discharge pipe. the phase difference;

[0060] Stage 310: Next, measure the current value of the current input compressor and the stroke phase difference, and compare the measured current value and stroke phase difference of the current input compressor with the preset current value and stroke phase difference respectively. Comparison, through the above comparison, when it is judged that the piston (10) has reached the discharge pipe, then perform the 320th stage downward; when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com