Sodium crown ether Salen Schief base isobi-metal condensation complex, preparation and use thereof

A Schiff base, bimetallic technology, applied in the polymer field, can solve the problems of limited use, difficult recovery and reuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

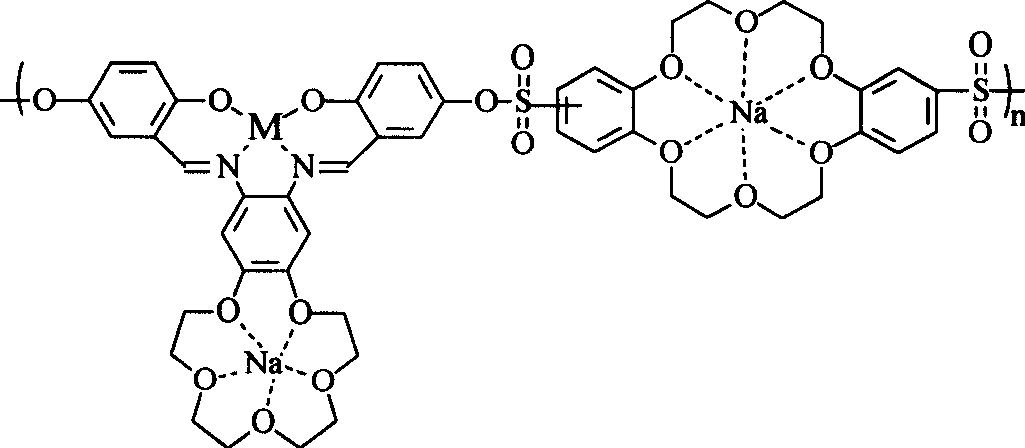

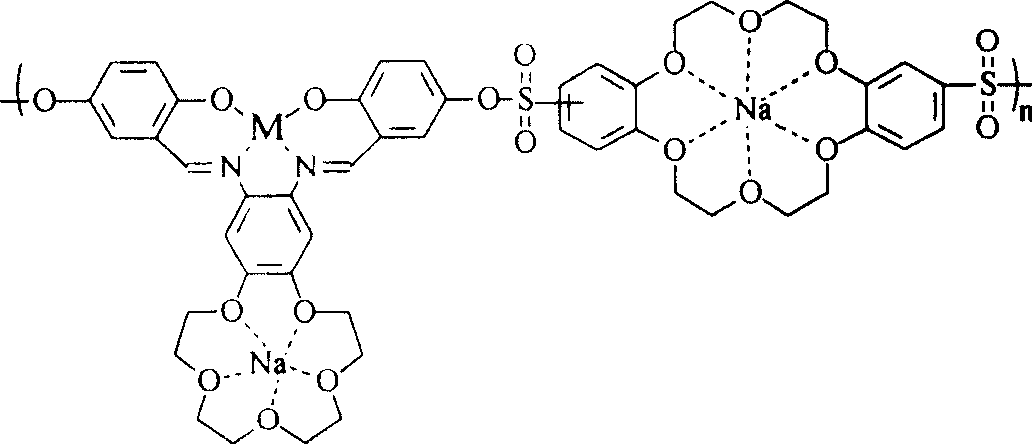

[0032] Embodiment 1, preparation of crown ether sodium-Salen Schiff base cobalt bimetallic polycondensation complex

[0033] ① Firstly, polycondensation reaction is carried out by 4', 5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 and di-m-dibenzocrown sulfonyl chloride to obtain solid polycondensation type Polymer (Sal-2NaCrown): fully dissolve 4',5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 in NaOH aqueous solution, under nitrogen protection, 30°C, Add the chloroform solution of bis-m-dibenzocrown sulfonyl chloride dissolved with 4', 5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 equimolar amount under high-speed stirring , kept the temperature constant, reacted for 1 hour, filtered with suction, washed with water, chloroform and DMF respectively, and dried in vacuum at 60°C for 72 hours to obtain a deep yellow flaky solid polycondensation polymer.

[0034] ② Reaction of the solid polycondensation polymer (Sal-2NaCrown) with the transition metal cobalt acetate to...

Embodiment 2

[0035] Embodiment 2, preparation of crown ether sodium-Salen Schiff base cobalt bimetallic polycondensation complex:

[0036] ① Firstly, polycondensation reaction is carried out by 4', 5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 and di-m-dibenzocrown sulfonyl chloride to obtain solid polycondensation type Polymer (Sal-2NaCrown): Fully dissolve 4',5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 in NaOH aqueous solution, under nitrogen protection at 15°C, at high speed Stir and add the chloroform solution of two-m-dibenzocrown sulfonyl chloride dissolved with 4', 5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 molar weight 2 times , kept the temperature constant, reacted for 3 hours, filtered with suction, washed with water, chloroform, and DMF respectively, and dried in vacuum at 90°C for 48 hours to obtain a dark yellow flaky solid polycondensation polymer.

[0037] ② Reaction of the solid polycondensation polymer (Sal-2NaCrown) with the transition metal cobalt acet...

Embodiment 3

[0038] Embodiment 3, preparation of crown ether sodium-Salen Schiff base cobalt bimetallic polycondensation complex:

[0039] ① Firstly, polycondensation reaction is carried out by 4', 5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 and di-m-dibenzocrown sulfonyl chloride to obtain solid polycondensation type Polymer (Sal-2NaCrown): fully dissolve 4',5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 in NaOH aqueous solution, under nitrogen protection, 0°C, Add the chloroform solution dissolved with 4',5'-bis(2-hydroxybenzylideneimino)benzo-15-crown-5 molar amount of 3 times bis-m-dibenzocrown sulfonyl chloride with high-speed stirring , kept the temperature constant, reacted for 5 hours, filtered with suction, washed with water, chloroform, and DMF respectively, and dried in vacuum at 120°C for 24 hours to obtain a dark yellow flaky solid polycondensation polymer.

[0040] ② Reaction of the solid polycondensation polymer (Sal-2NaCrown) with the transition metal cobalt aceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com