Method and apparatus for printing with identifying code of laser beam

A technology of identification codes and laser beams, applied in the field of printing and installation of identification codes using laser beams, can solve problems such as expansion of installation locations, reduction in productivity, deviation of irradiation points, etc., and achieve the effect of eliminating deviation of irradiation time difference and uniform concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

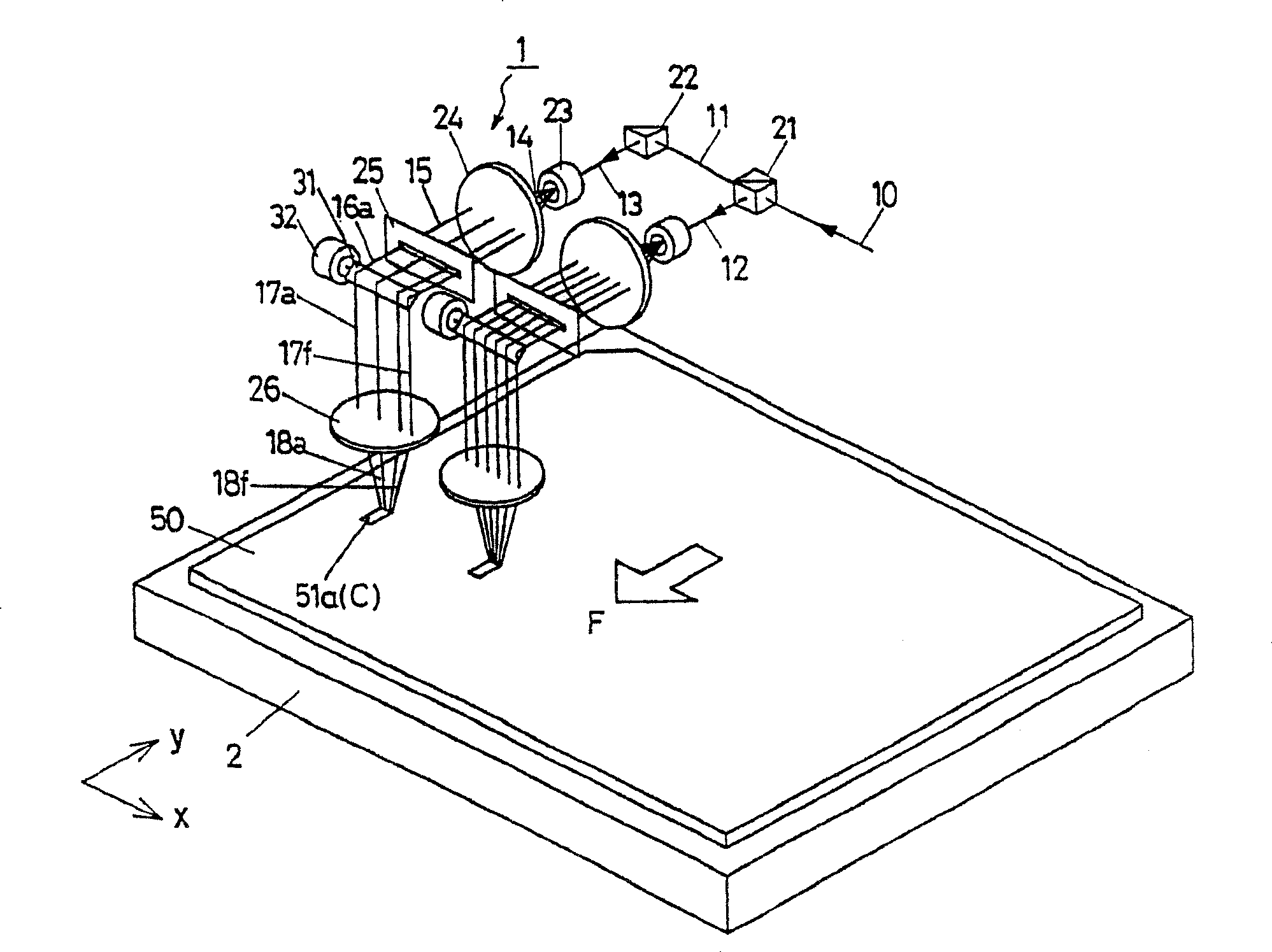

[0104] Using figure 1 When the identification code printing device of the company prints the identification code on the substrate coated with photoresist, as the laser beam, the laser beam near the wavelength λ=335nm of the third harmonic wave of the YAG laser is used as the laser beam coated on the substrate. A photoresist is chosen that is sensitive to that wavelength.

[0105] The pulse frequency f of the laser beam is set as f=60kHz, the width of the working surface of the laser beam when it is set to focus on the substrate is W=0.050mm, and the interval between adjacent beams is p=0.050mm. The speed v=500 mm / sec for moving the table in the thickness direction.

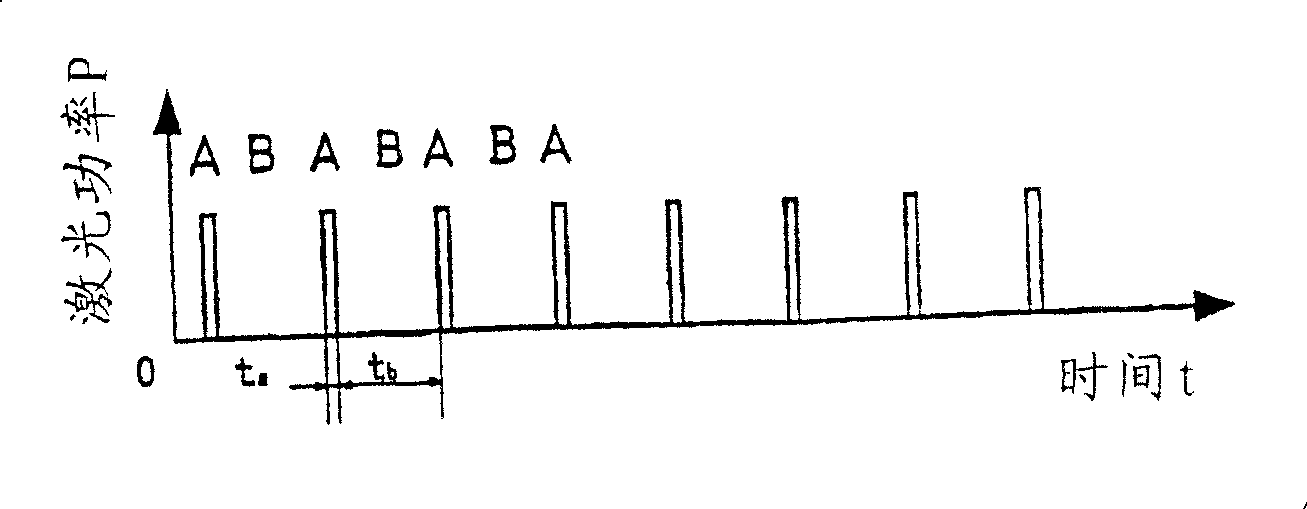

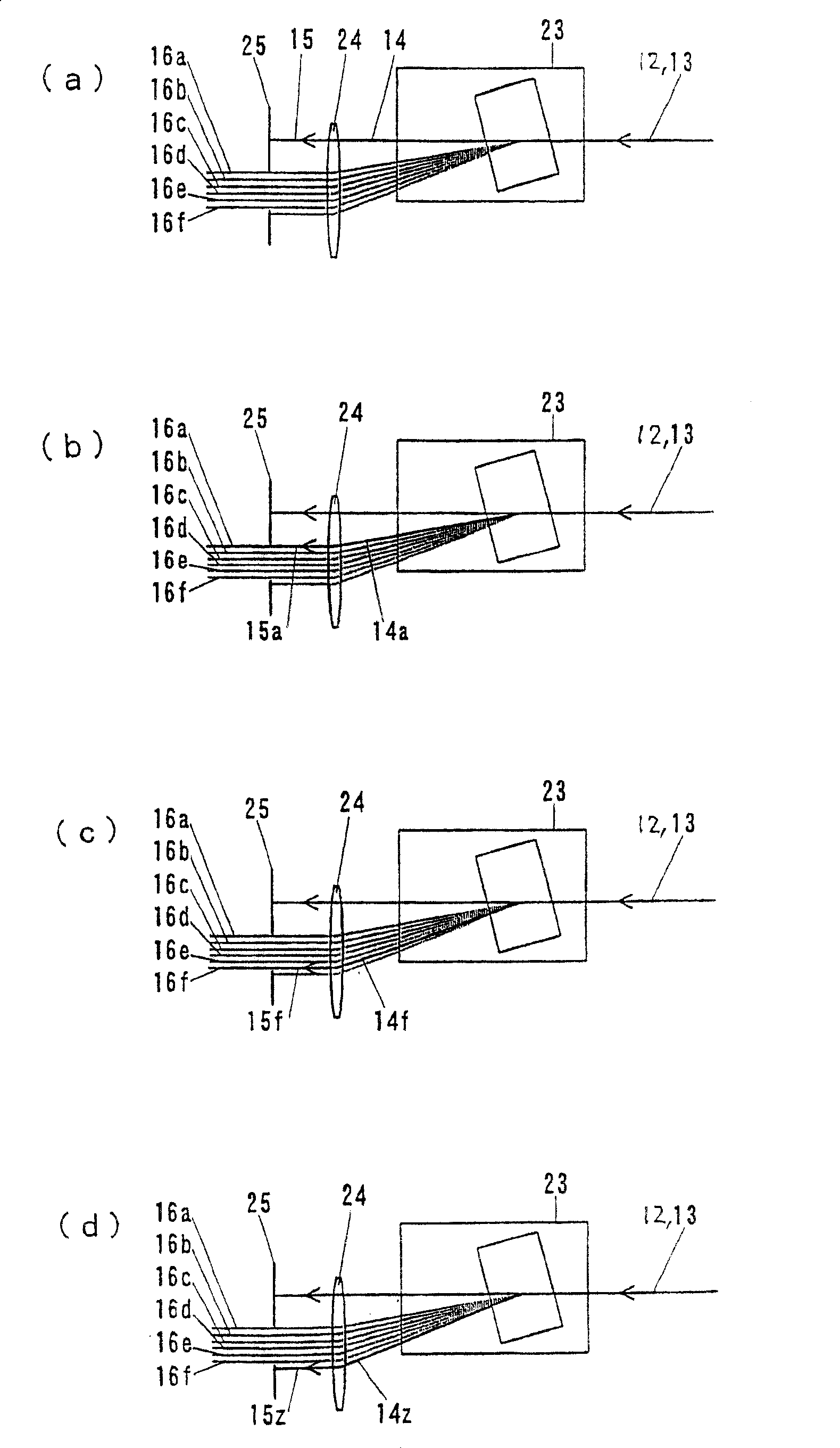

[0106] In addition, the laser beam is deflected 7 stages by the beam deflection mechanism, and the beams in 6 directions are irradiated on the substrate through the transmission filter 25, and the beams in 6 directions are selectively irradiated at 10 kHz.

[0107] According to the above setting, the distance D...

Embodiment 2

[0122] Using Figure 17 When printing the identification code on the substrate, the printing device uses a laser beam with a wavelength λ=355nm of the third harmonic of the YAG laser as the laser beam, and selects this wavelength as the photoresist coated on the substrate. Photosensitive resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com