Transparent heat-insulating film and its preparing process

A technology of heat insulation film and transparent film, which is applied in the field of transparent heat insulation film containing nanoparticles and its preparation, can solve the problems of inability to directly use film materials, complicated preparation methods, etc., and achieves good light transmittance, simple preparation method, good The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1: PVC-based transparent thermal insulation film, composed of a transparent substrate and a coating film, the thickness of the coating film is 10 μm. The composition and structure of the heat insulation film are shown in Table 1:

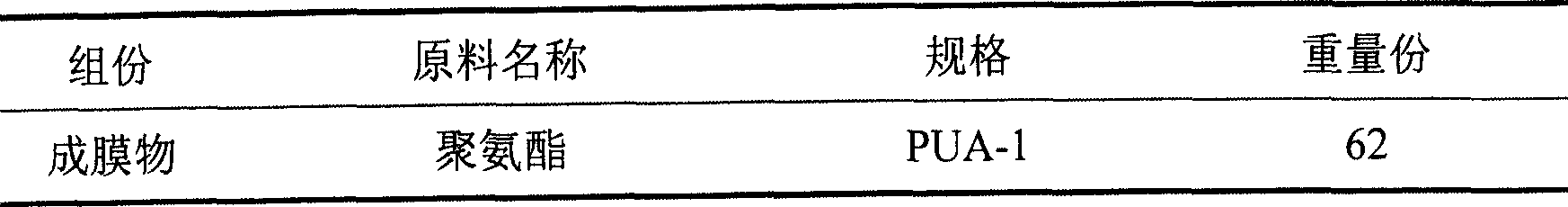

[0028] Table 1 Composition of transparent thermal barrier coating

[0029]

[0030]

[0031] Stretch and flatten the PVC film through the fixture frame, apply the transparent heat-insulating paint on the PVC substrate by brushing, and dry it at 60°C for two hours to form a film, forming a PVC-based transparent heat-insulating film. This heat-insulating film has Good heat insulation performance and visible light transmittance, after relevant tests and calculations, its light transmittance reaches 80%, and its red shielding rate reaches 63%.

example 2

[0032] Example 2: PVB-based transparent heat-insulating film, composed of a PVB substrate and a layer of coating film, the thickness of the coating film is 15 μm. The composition and composition of the coating are shown in Table 2.

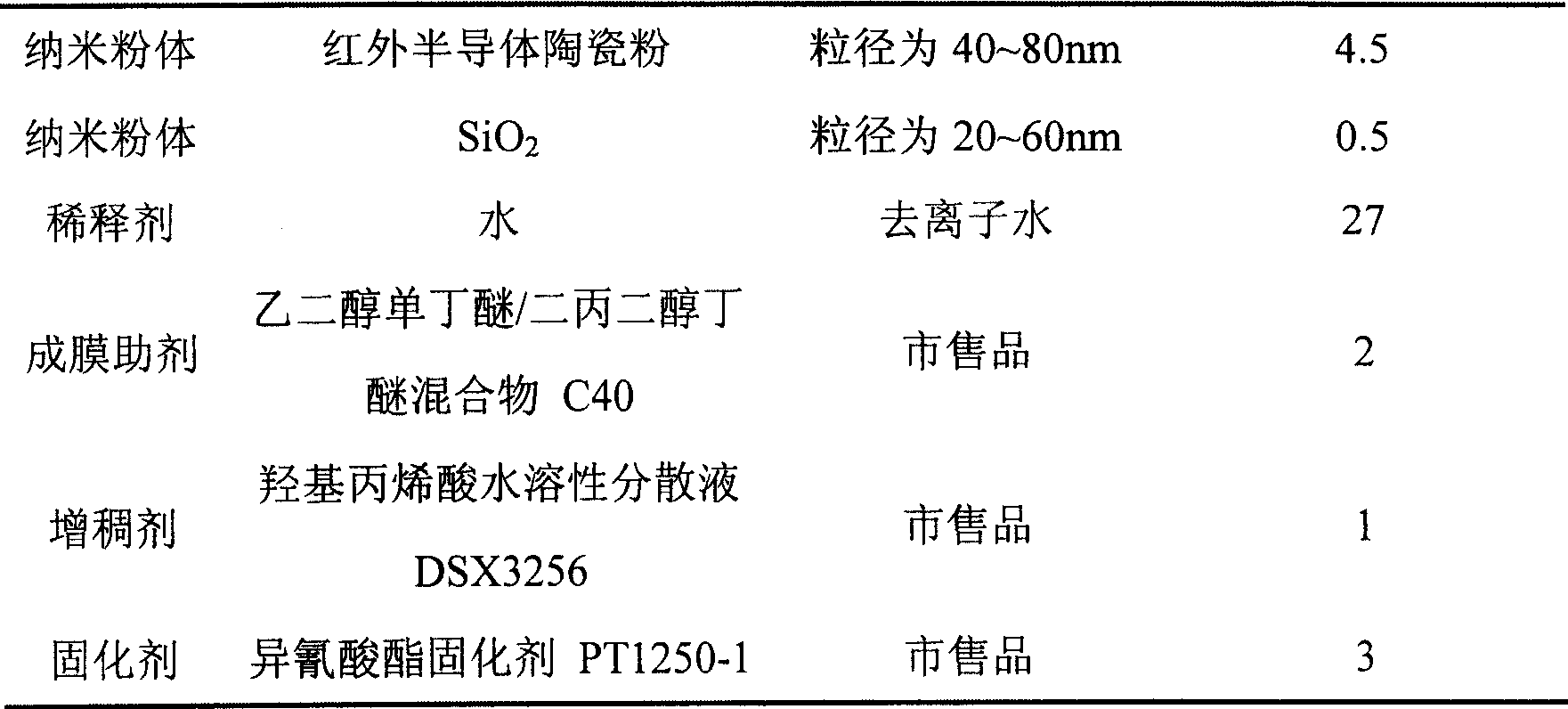

[0033] Table 2 Composition of transparent thermal barrier coating

[0034]

[0035] Apply the transparent thermal insulation coating on the PVB substrate by spraying, and dry it at 80°C for 2 hours to form a film. This thermal insulation film has good thermal insulation performance and visible light transmittance. After relevant tests and calculations, its visible light The light transmittance in the region can reach 78%, the shielding rate of light in the near-infrared region can reach 80%, and the shielding rate of ultraviolet light can reach 98%, with excellent comprehensive performance.

example 3

[0036] Example 3: PC-based transparent heat-insulating film, consisting of a PC substrate and a layer of coating film, the thickness of the coating film is 40 μm. The composition and composition of the coating are shown in Table 3.

[0037] Table 3 Composition of transparent thermal barrier coating

[0038]

[0039] Stretch and flatten the PC film, apply the transparent thermal insulation coating on the PC substrate by brushing, and dry it at 100°C for 1 hour to form a film. This thermal insulation film has good thermal insulation performance and visible light transmittance , after relevant tests and calculations, its light transmittance in the visible light region can reach 75%, and the shielding rate of light in the near-infrared region can reach 60%, with excellent comprehensive performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com