Thermal field structure of polysilicon ingot furnace

A polycrystalline silicon ingot furnace and thermal field technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve problems such as difficulty in meeting production requirements and insufficient structural design, and achieve the effects of reasonable design, shortening process time, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

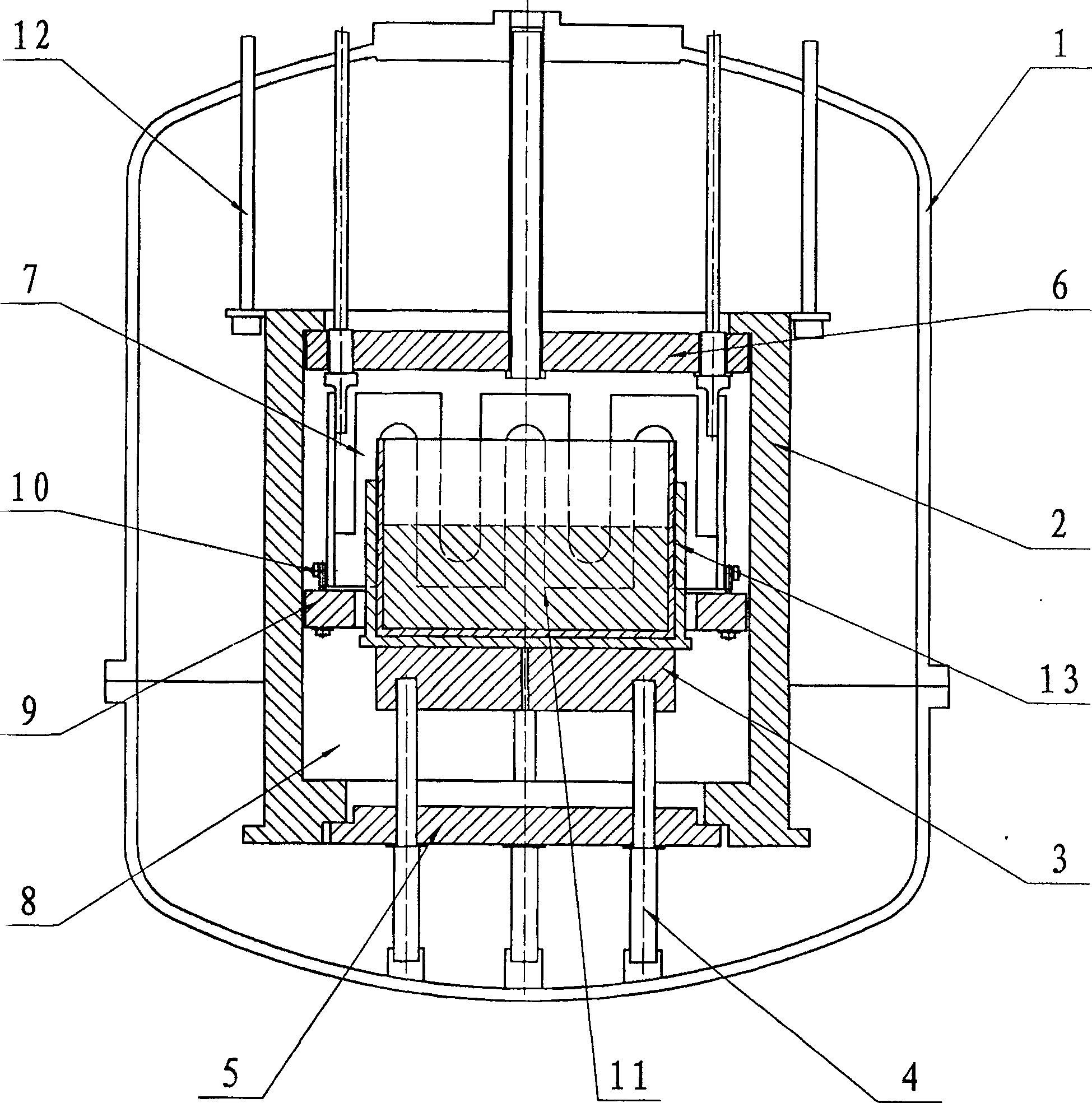

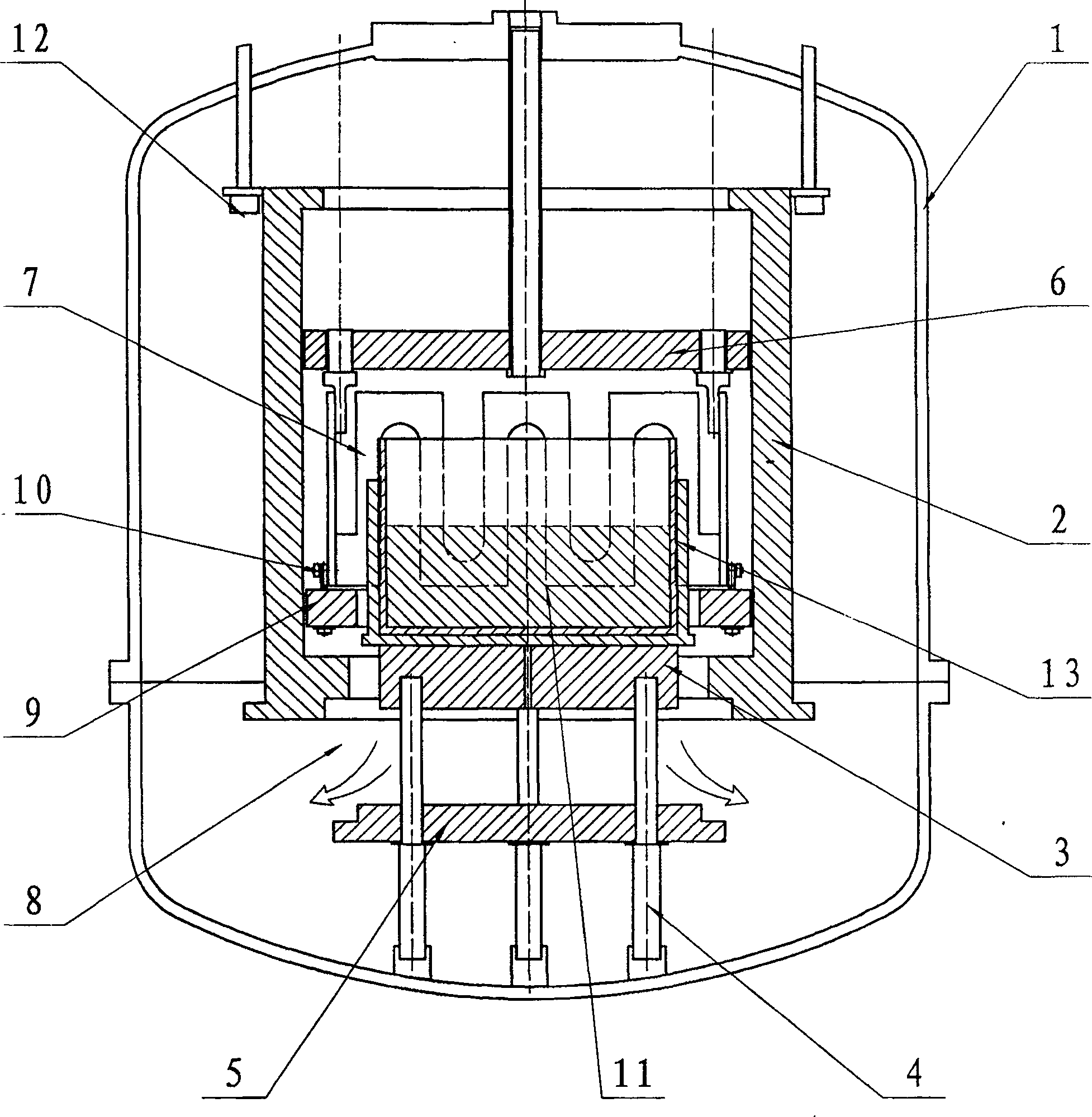

[0011] The present invention mainly consists of a furnace body 1, a thermal insulation cage 2 with suspenders 12 placed in the furnace body 1, a thermal insulation roof 6 placed on the upper part of the thermal insulation cage 2, and a thermal insulation cage with a pillar 4 in the lower part. The bottom plate 5 is placed in the thermal insulation cage body 2 and fixed on the heater 7 on the thermal insulation top plate 6, fixed on the heat exchange table 3 with a crucible 13 on the top of the pillar 4, and placed between the heater 7 and the heat exchange table 3 The bottom of the pillar 4 is fixed on the bottom of the furnace body 1, and the heat insulation ring 9 is fixedly connected with the heat insulation top plate 6 through the connector 10.

[0012] The present invention will be further described below in conjunction with the production process of polysilicon:

[0013] Fill the crucible 13 with the polysilicon raw material 11, put it on the heat exchange table 3, opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com