Boring, milling machine primed by straight-line driven portal shaped in zero phase on beam of magnetic suspension

A technology of linear drive and control method, which is applied in the field of numerical control, and can solve problems such as friction and heat generation, reduction of motion pair precision, damage to micro-feed, high-precision, high-response feed performance requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

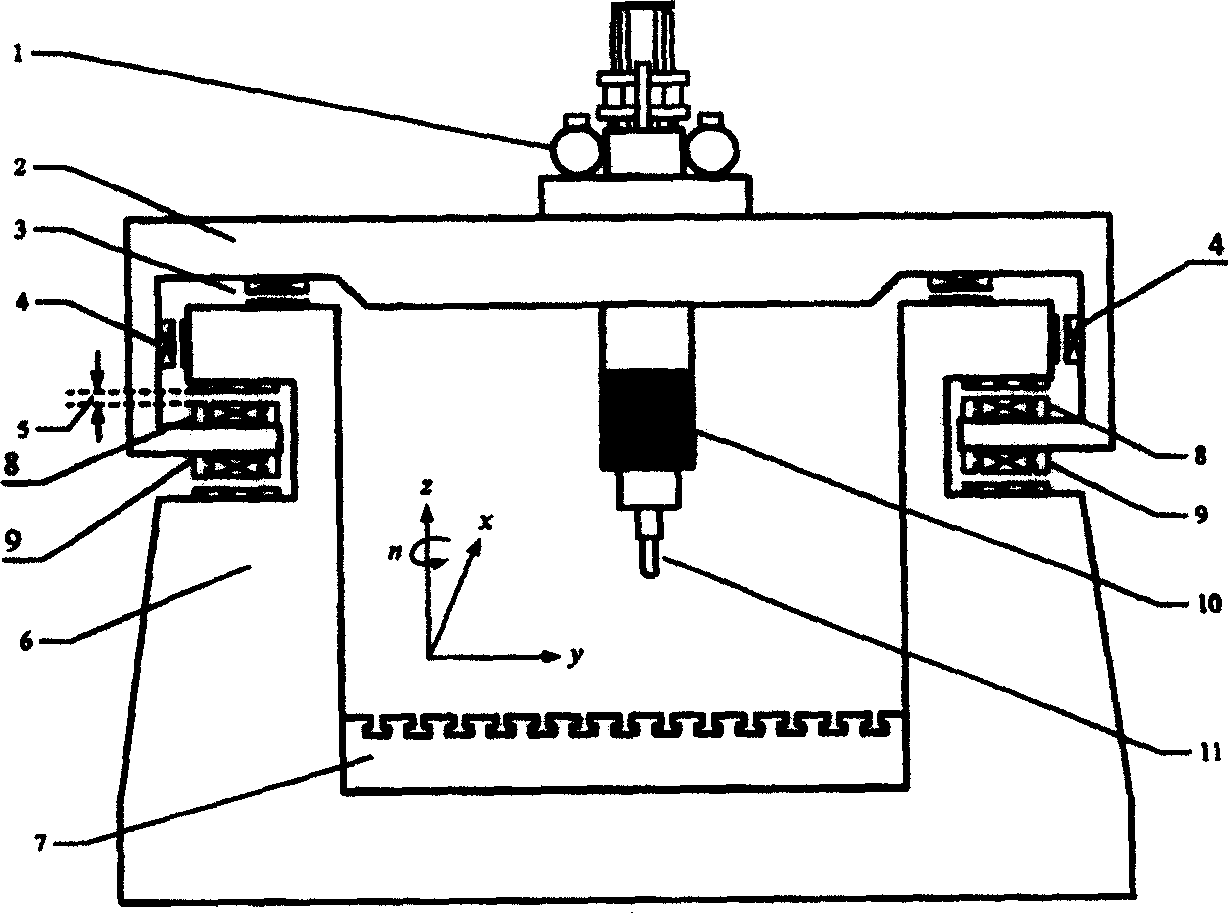

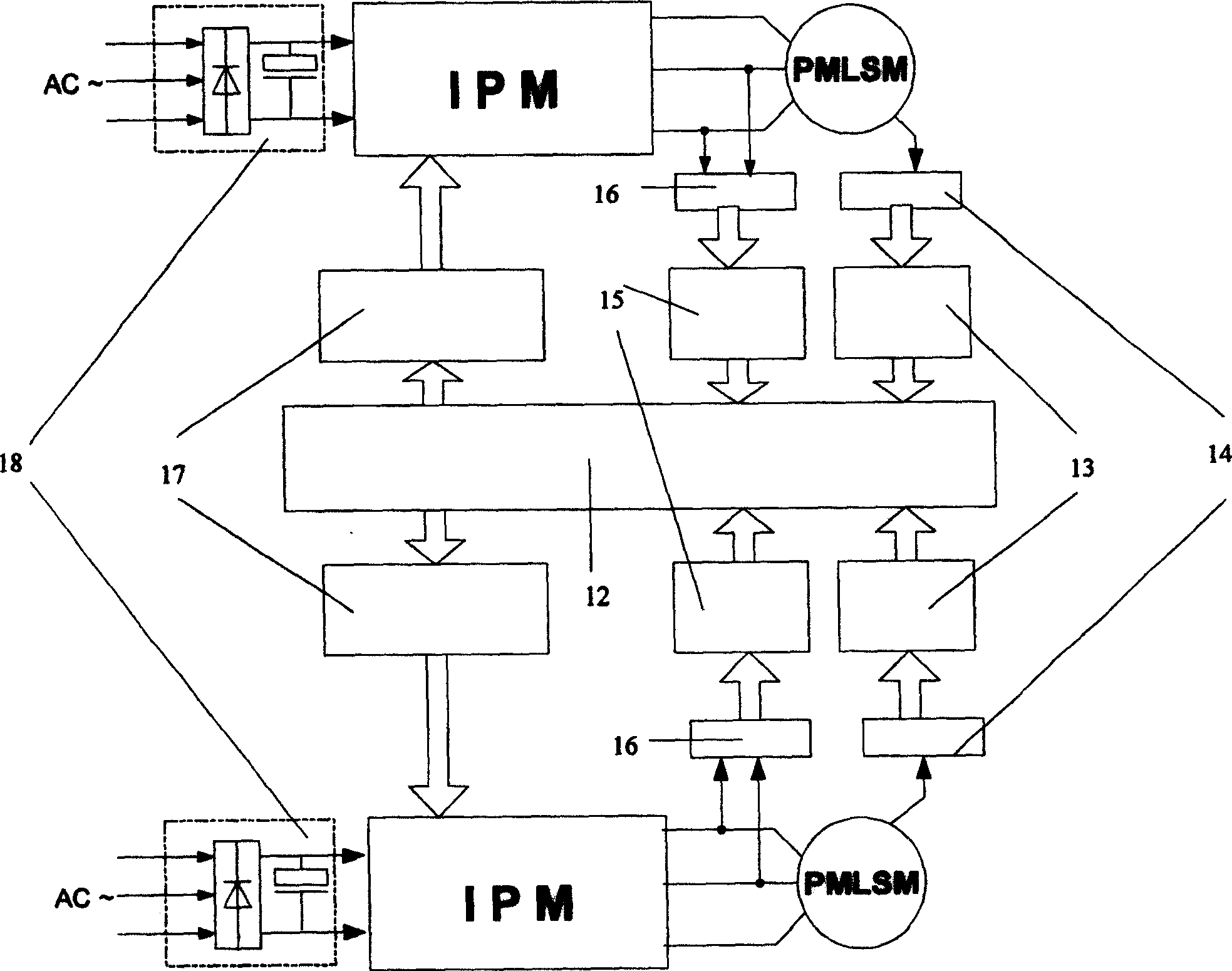

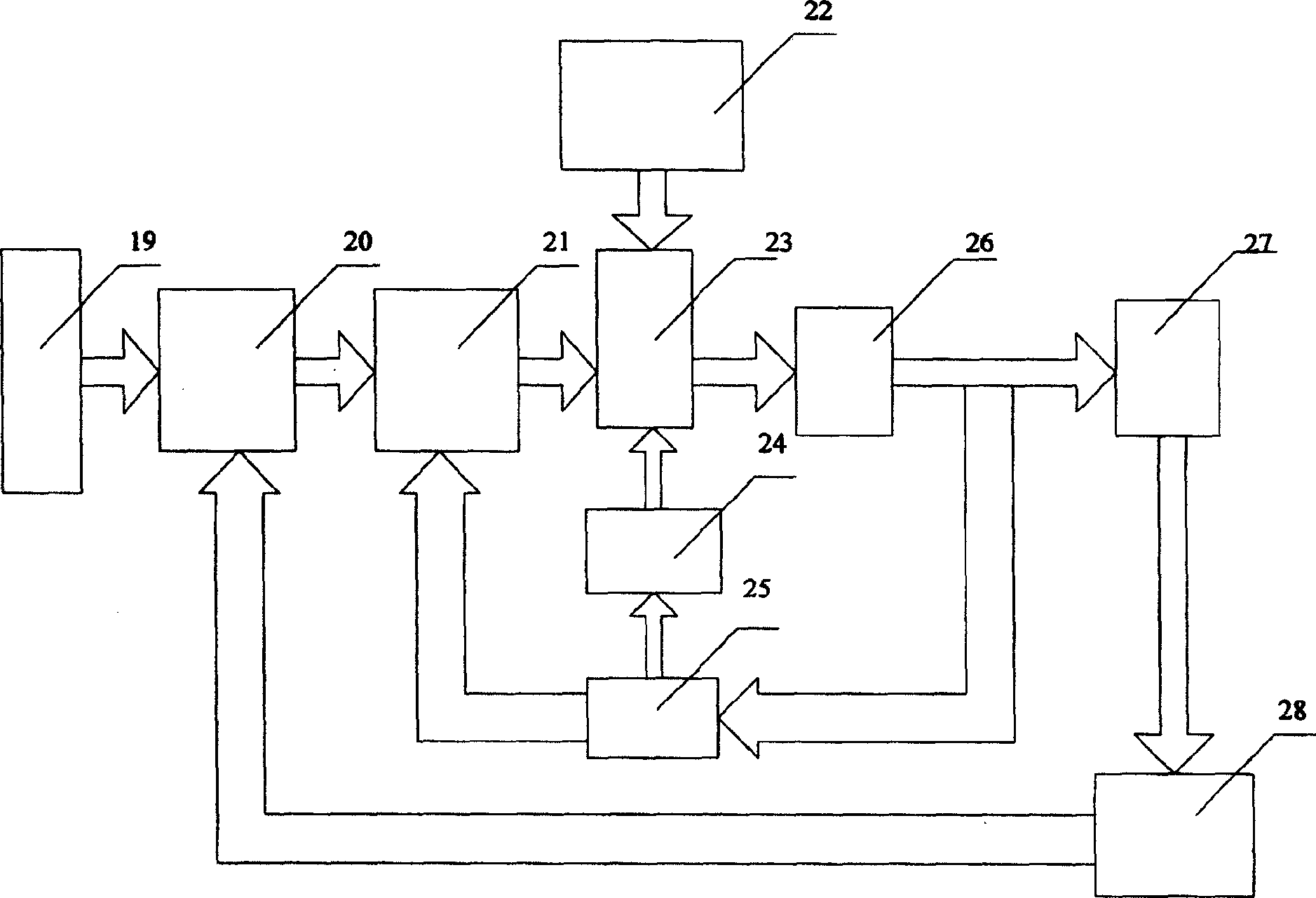

[0118] A preferred embodiment of the present invention see figure 1 , Figure 11 and Figure 12.

[0119] Such as figure 1As shown, the gantry mobile processing machine driven by the magnetic levitation beam linear motor part includes a servo unit (including servo motor and sensor, servo driver), box-type beam, X-direction linear motor, guide unit (including motor, sensor and driver), beam suspension Air gap, U-shaped integrated bed, worktable, main suspension electromagnet, compensation electromagnet, spindle unit (spindle drive motor and sensor, spindle driver) and tool, the main suspension electromagnet coil is connected with the inner extension of the beam end , the armature is on the bed, and the coils of the main suspension electromagnet are divided into two rows on the left and right, which act as a suspension beam. The connection between the compensation electromagnet and the main suspension electromagnet is similar, that is, the main suspension electromagnet is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com