Use of microwave energy to disassemble, release, and hydrate contact lenses

A technology of contact lens and separating agent, applied in application, glasses/safety glasses, glasses/goggles, etc., can solve disadvantages and other problems, achieve the effect of reducing extraction time and simplifying hydration equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

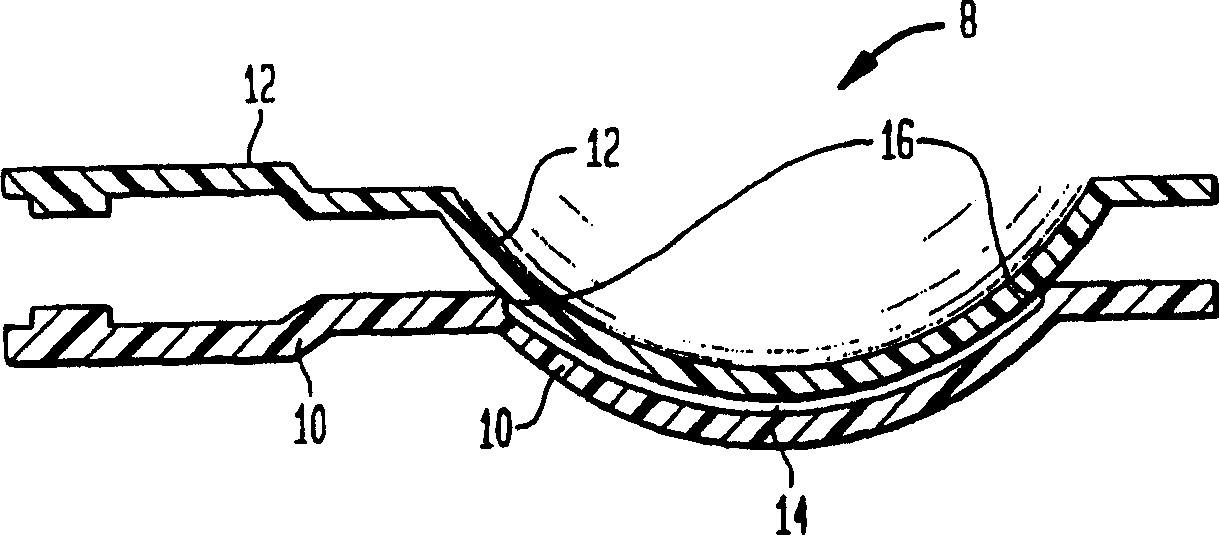

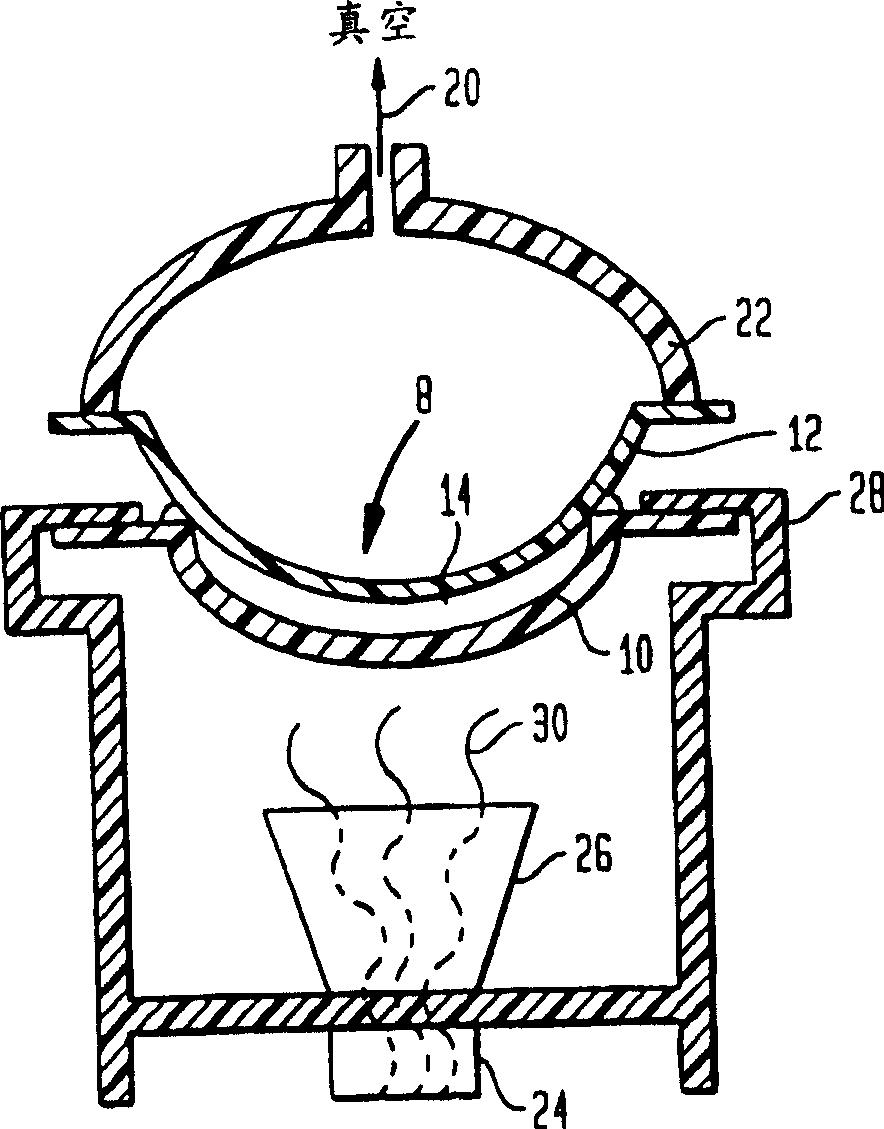

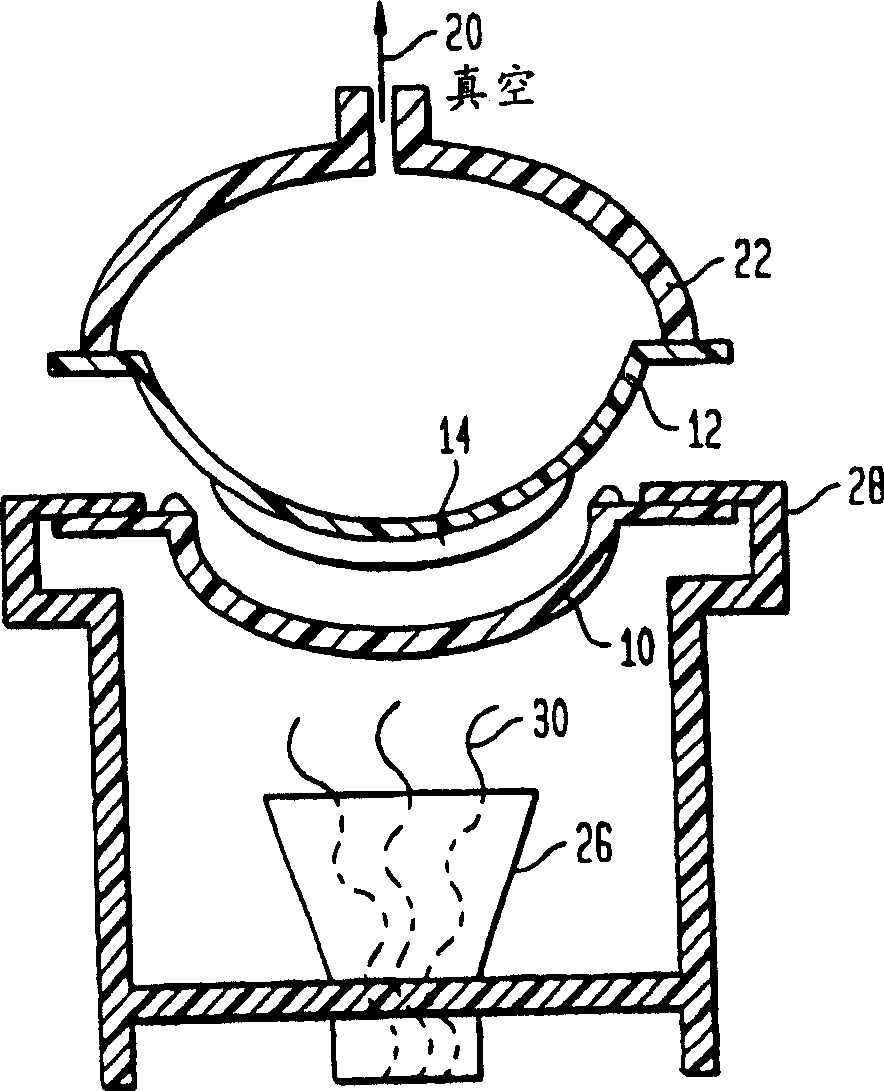

[0037] figure 2 A contact lens / mold assembly 8 comprising an anterior curvilinear mold and a substantially curvilinear mold is shown where a hydrogel soft contact lens is molded in the mold assembly according to figure 1 way of giving some instructions. The contact lens / mold assembly 8 is supported by a vacuum 20 controlled conveyor 22 which utilizes vacuum to hold the posterior curve mold 12 in place.

[0038]The lens / mold assembly 8 is placed in a microwave heating and processing demolding position where there is a microwave generator 24, a microwave waveguide 26, or also includes a microwave valve. The microwave waveguide 26 can be made from low cost sheet metal, the cost of which is already built into the design. The waveguide is practically 100% effective in containing and directing microwaves, and in addition, the waveguide is not subject to accelerated corrosion during the application of the present invention due to the various separations, washes, and DI solutions u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com