Lateral alternate arranged grate of incinerator and compensation device

A compensating device and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as time-consuming, large number of bolts, slag leakage, etc., to reduce labor intensity, ensure air supply volume, and operate space big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

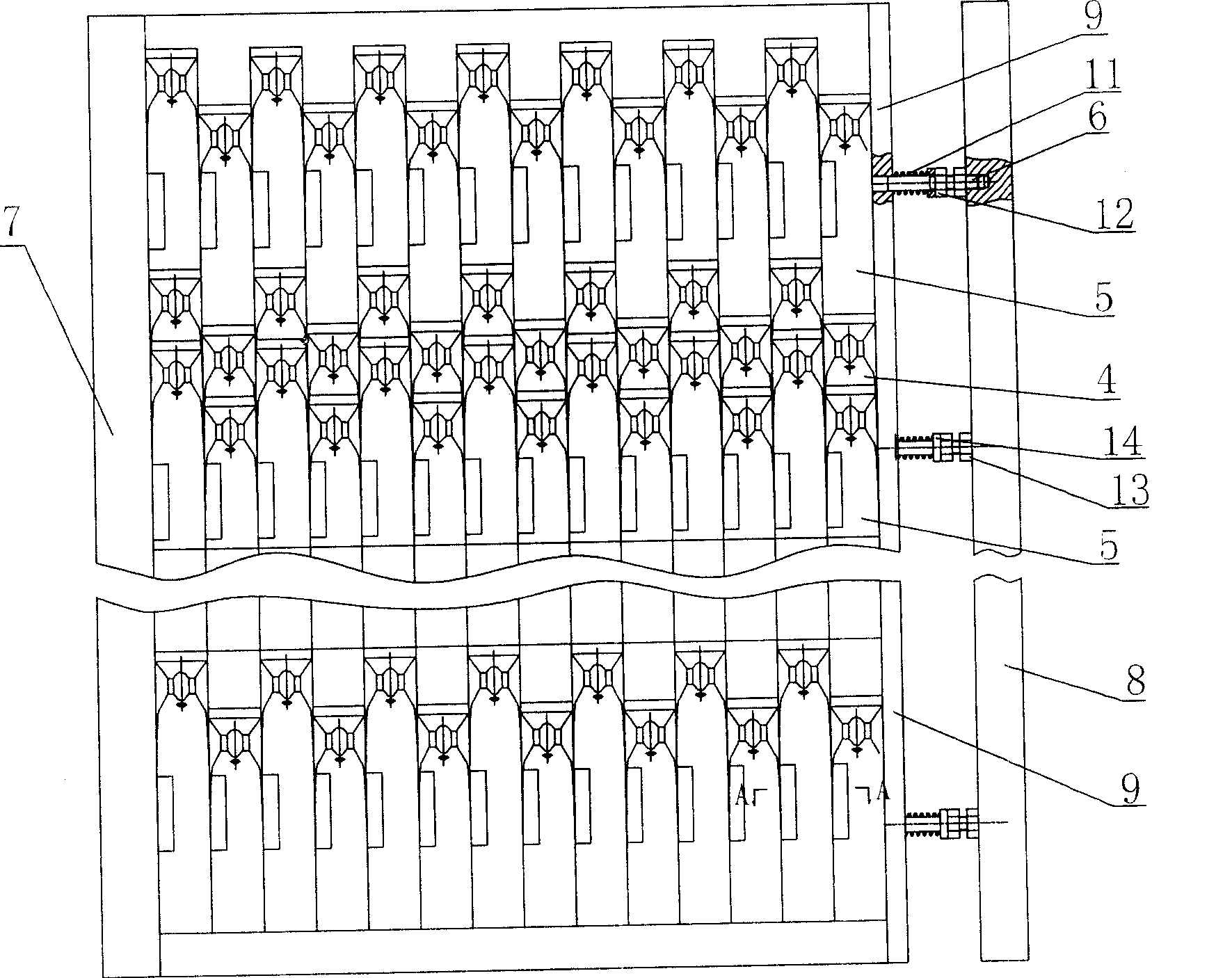

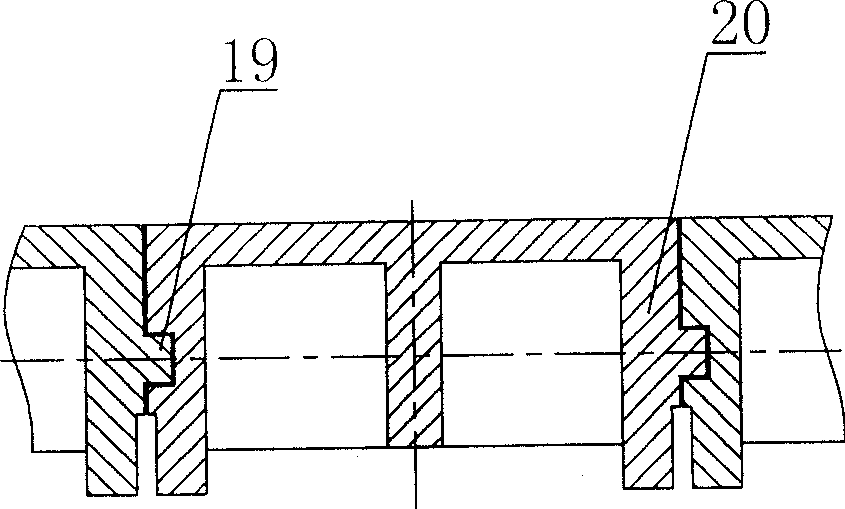

[0036] Please refer to Fig. 5 and Fig. 6, the most basic unit grate piece in the incinerator grate of the present invention is mainly composed of an upper surface 20, a bottom, a front side 17, a rear side 15, a left side 18, and a right side 16. The slats are provided with a boss 10 at the front end of the upper surface, and an air outlet 21 is opened on the boss 10. The air outlet 21 communicates with the air duct arranged at the bottom, and an arc-shaped slot 22 is opened at the tail end of the bottom. On the left side 18 of the grate piece, there is a rectangular draw-in slot, and on the right side 16, a rectangular protrusion 19 is arranged.

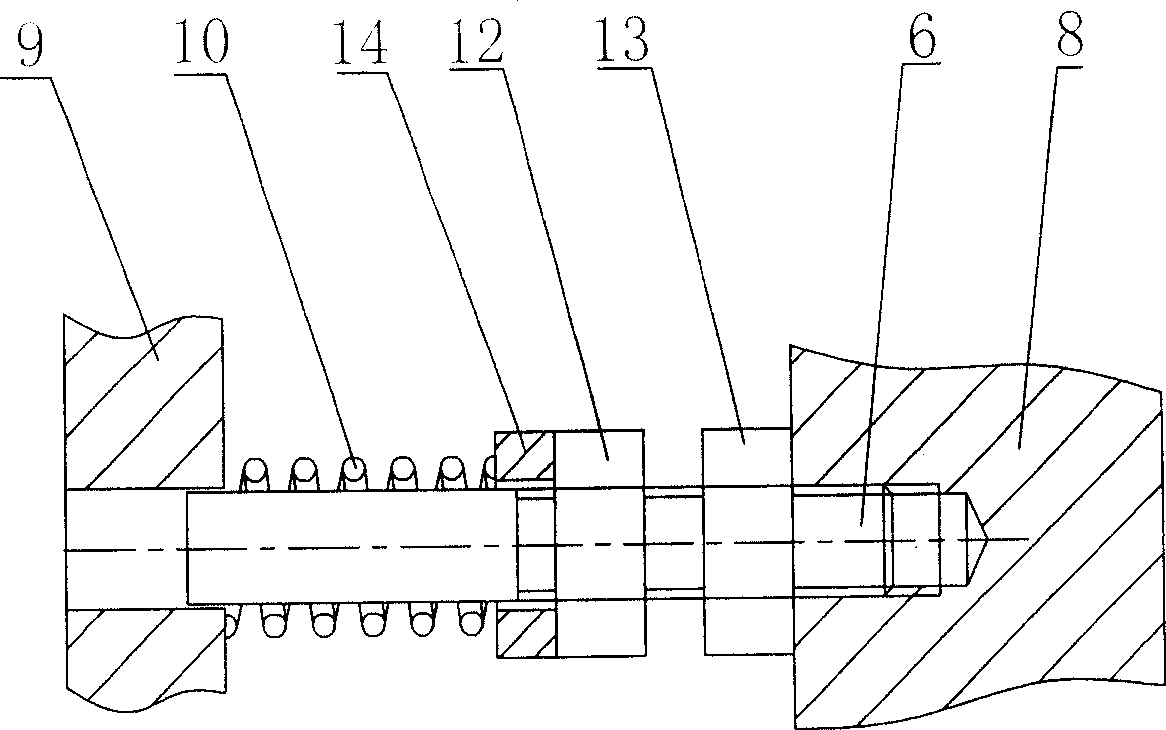

[0037] Please see Fig. 4 again, the front portion of the movable grate plate 4 is overlapped on the fixed grate plate 5, the upper surface of the fixed beam 1 is distributed with a pin 1a, the top of the pin 1a is a spherical surface, and the spherical surface snaps into the In the arc-shaped draw-in groove 22 of the fire grate shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com