Brake actuating system using an electric motor

一种刹车片、致动装置的技术,应用在刹车致动装置领域,能够解决结构复杂、生产成本增加、难制造和装配等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

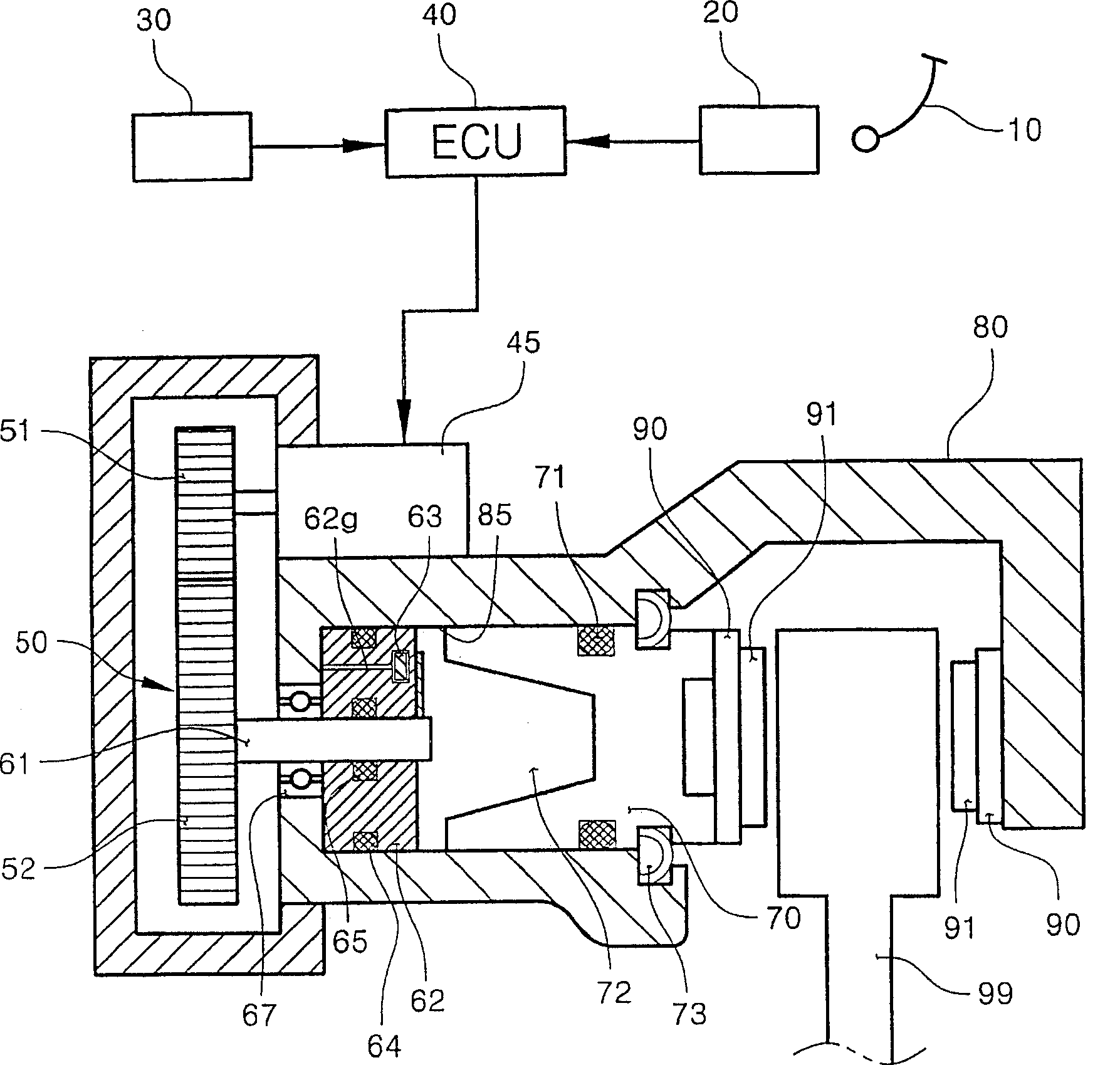

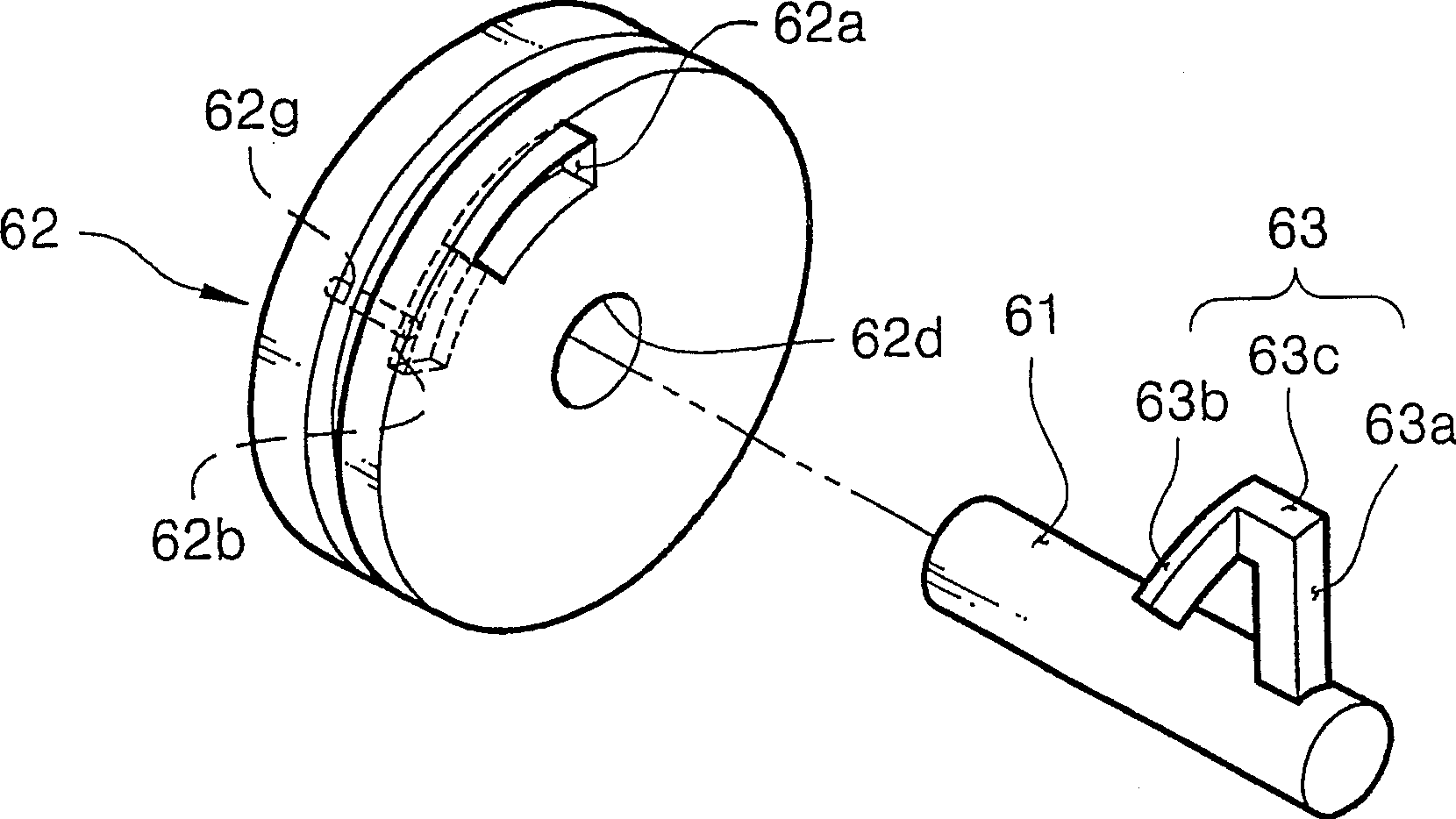

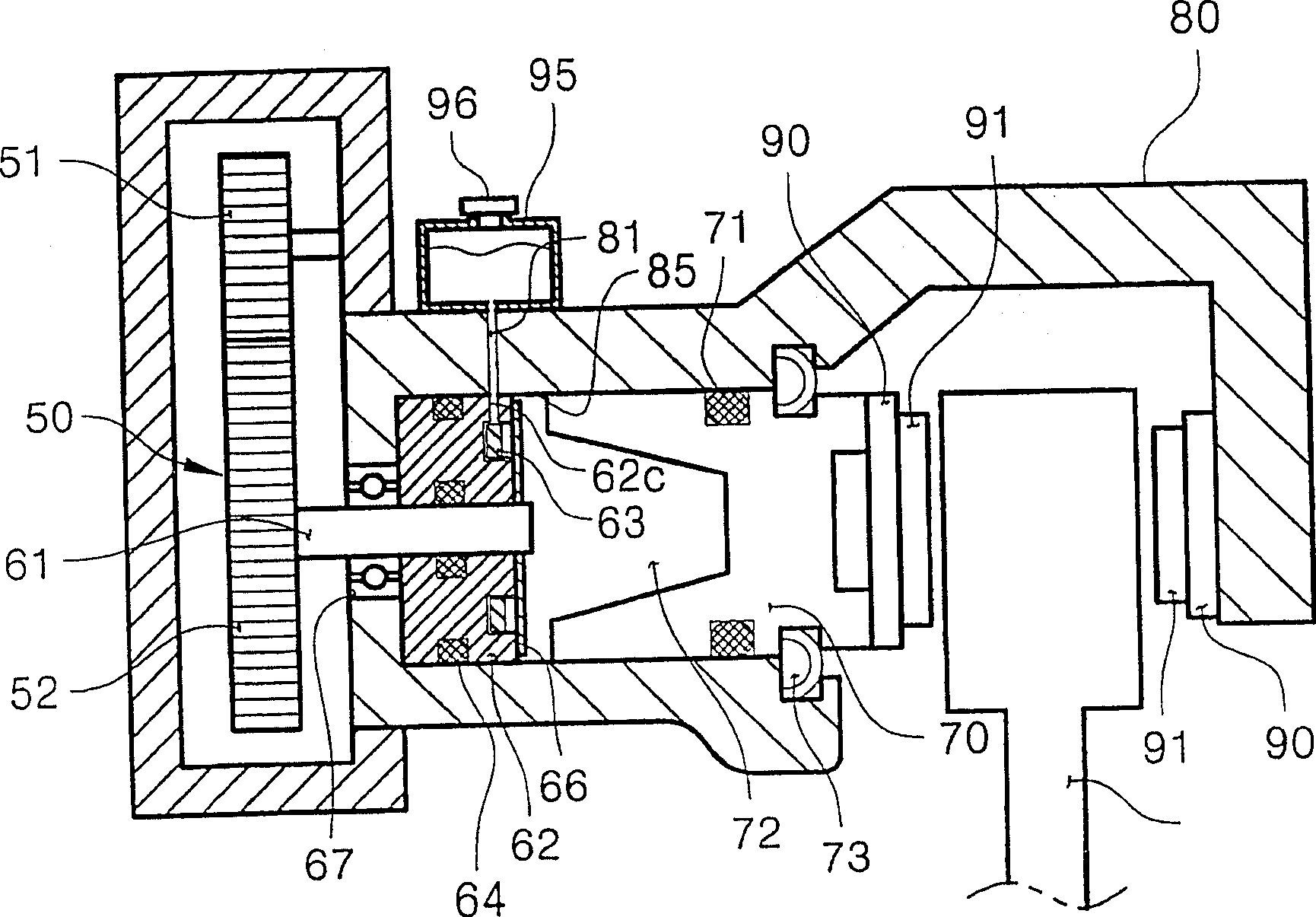

[0041] figure 1 is a schematic diagram of a brake actuating device according to an embodiment of the present invention, figure 2 yes figure 1 A perspective view of one embodiment of the housing and fluid booster components of the brake actuating device shown in FIG.

[0042] Such as figure 1 As shown in , the brake actuating device of this embodiment includes: a clamp body 80 with a cylinder 85; a motor 45 fixed to the clamp body 80; a pressure piston 70 installed in the cylinder 85; a housing 62, which Spaced from the pressure piston 70 with a predetermined distance in the back, and is fixedly installed on the cylinder 85 to maintain airtightness with the inner circumference of the cylinder 85; the rotating shaft 61 installed in the center of the housing 62 is transmitted by the motor 45 and the power transmission mechanism 50 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com