Monochip color wheel and its making process

A manufacturing method, a single-chip technology, applied in the direction of image duplicators, optical filters, color TVs, etc., can solve the problems of high noise, reduced lifespan, and quality reduction of color wheel filters, etc., to achieve low noise and smooth operation , Improve the effect of dynamic imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention proposes a monolithic color wheel and its manufacturing method. The manufacturing method of the monolithic color wheel is to form two or more than two kinds of color filter films on a square transparent substrate, and then cut into a The circular color wheel filter can be directly glued to a motor, or indirectly connected to a motor by using a metal ring to be driven by it.

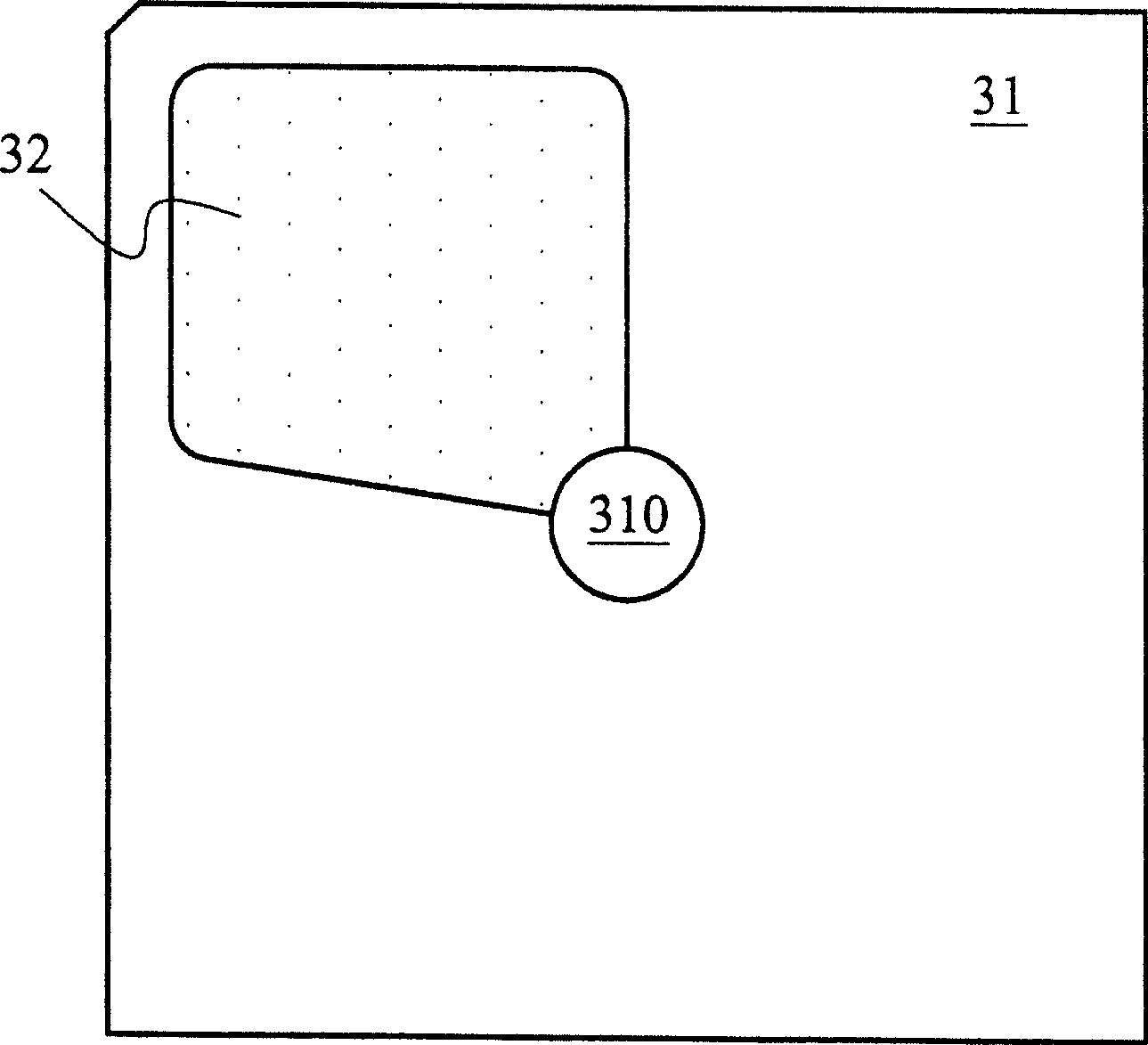

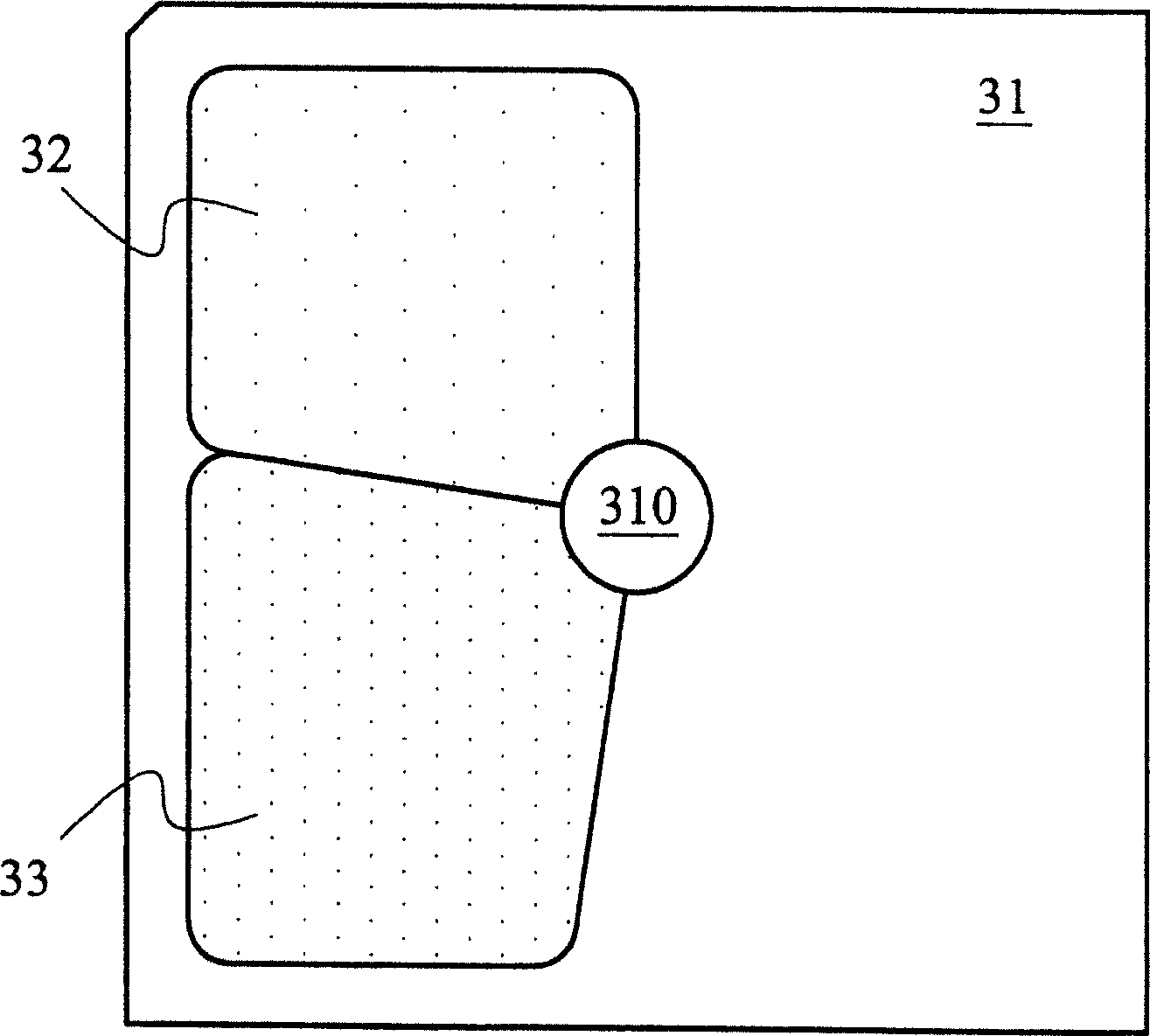

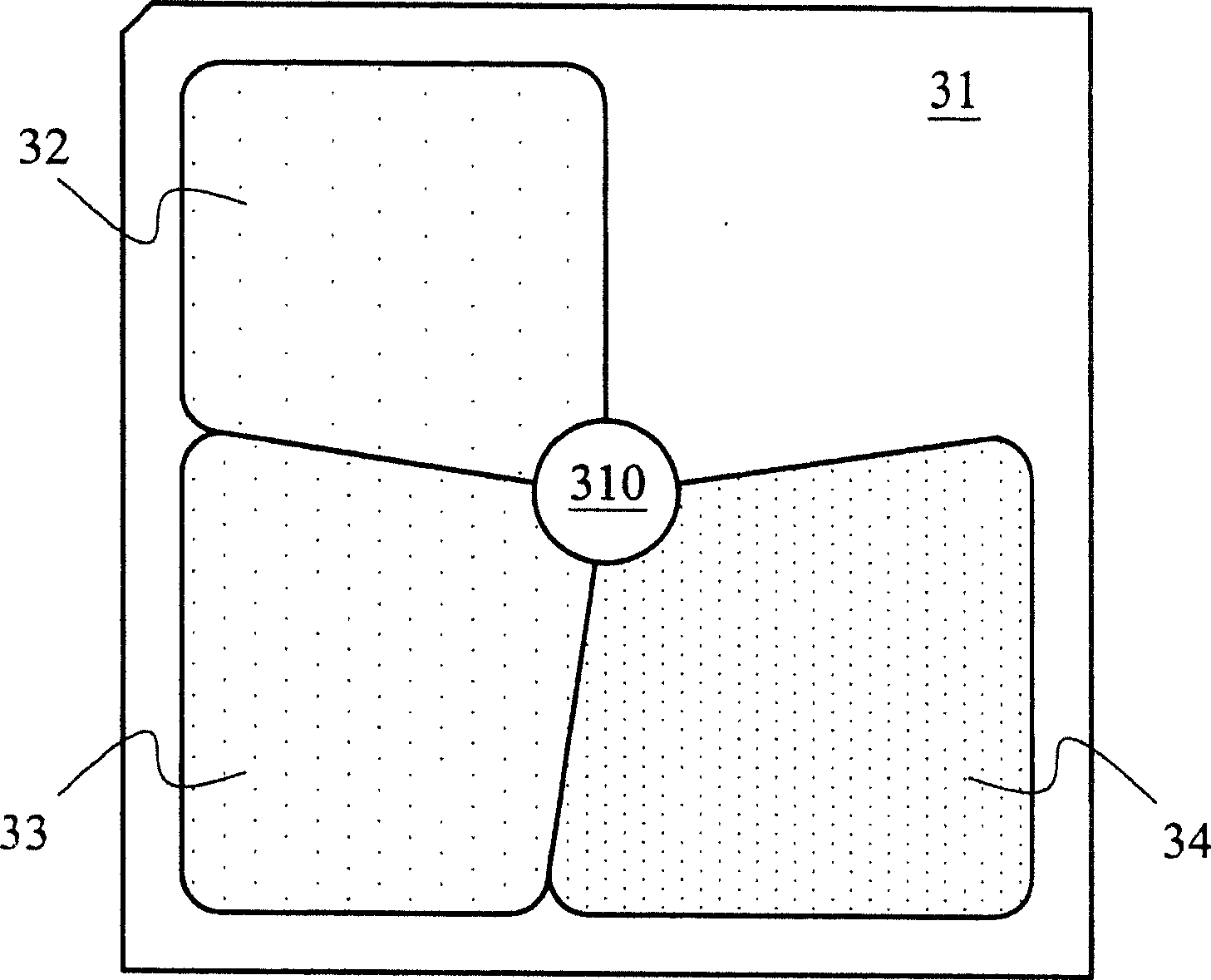

[0025] According to the manufacturing method implemented by the present invention, its steps may include: a first step, such as Figure 1 to Figure 4 Shown, be to plate the light filter film 32 of the first kind of color, the light filter film 33 of the second kind of color, the light filter film 34 of the third kind of color on a square substrate 31, and the light filter film of the fourth kind of color film35. The square substrate 31 can be made of glass plastic or quartz, and the filter films can be red, green or blue filter films respectively. Preferably, in order to improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com