Open type air-conditioning compressor shaft gland device

An air-conditioning compressor, an open-type technology, applied in the field of air-conditioning compressors, can solve the problems of deformation under force, reducing the sealing performance of the sealing surface 18', and damage to the sealing oil film, and achieves improved impact resistance, compact shaft seal structure, and isolation. The effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

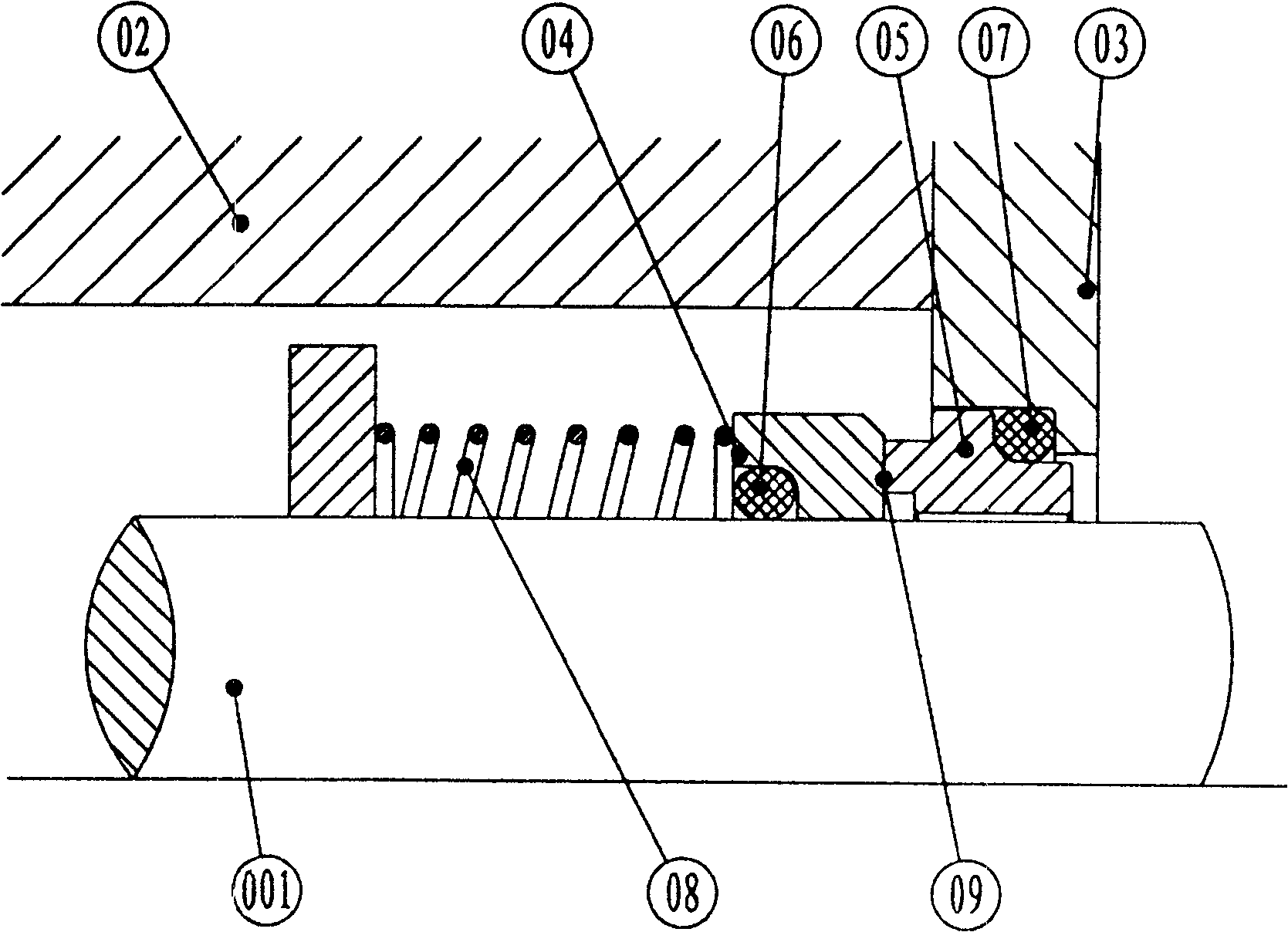

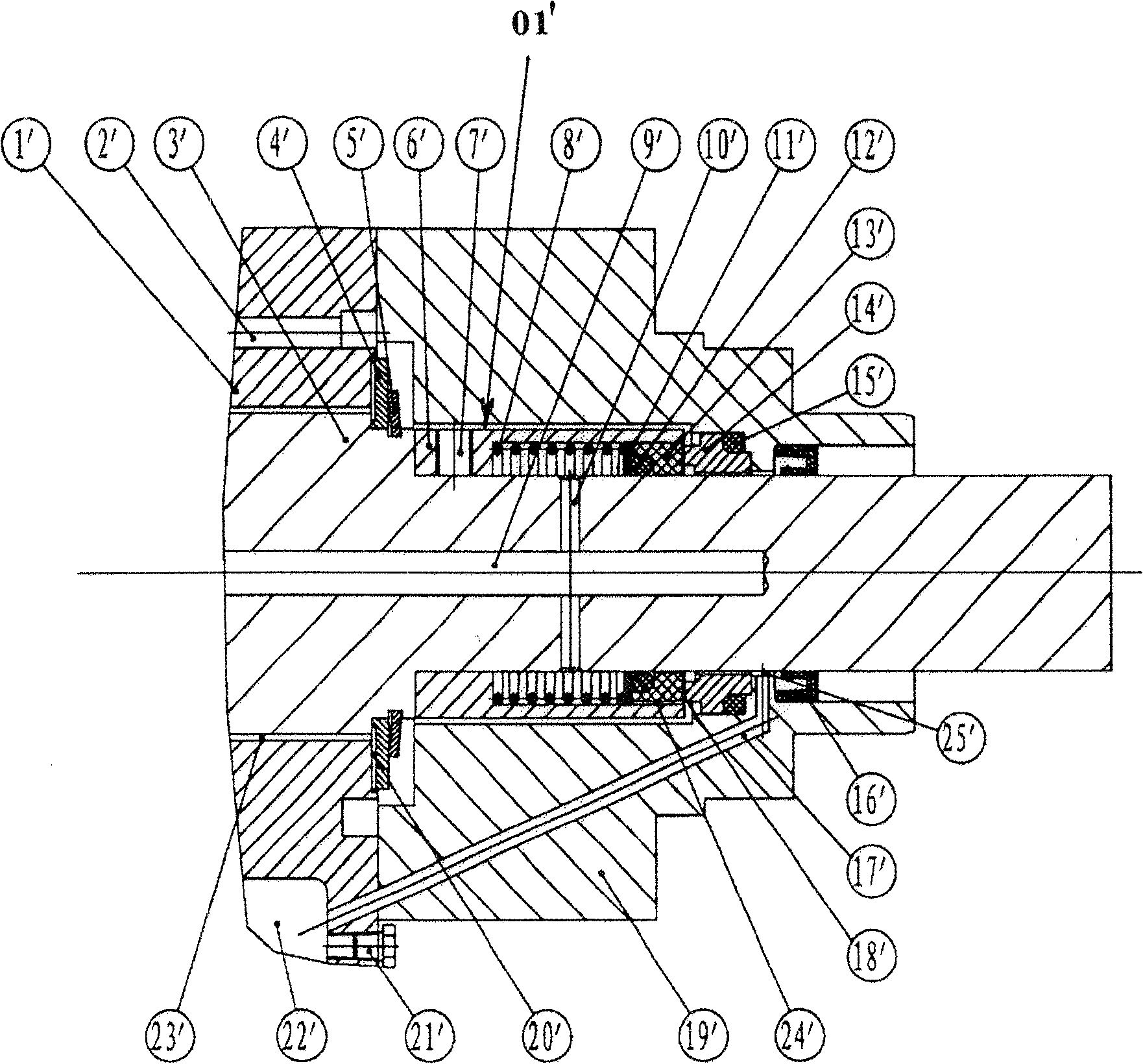

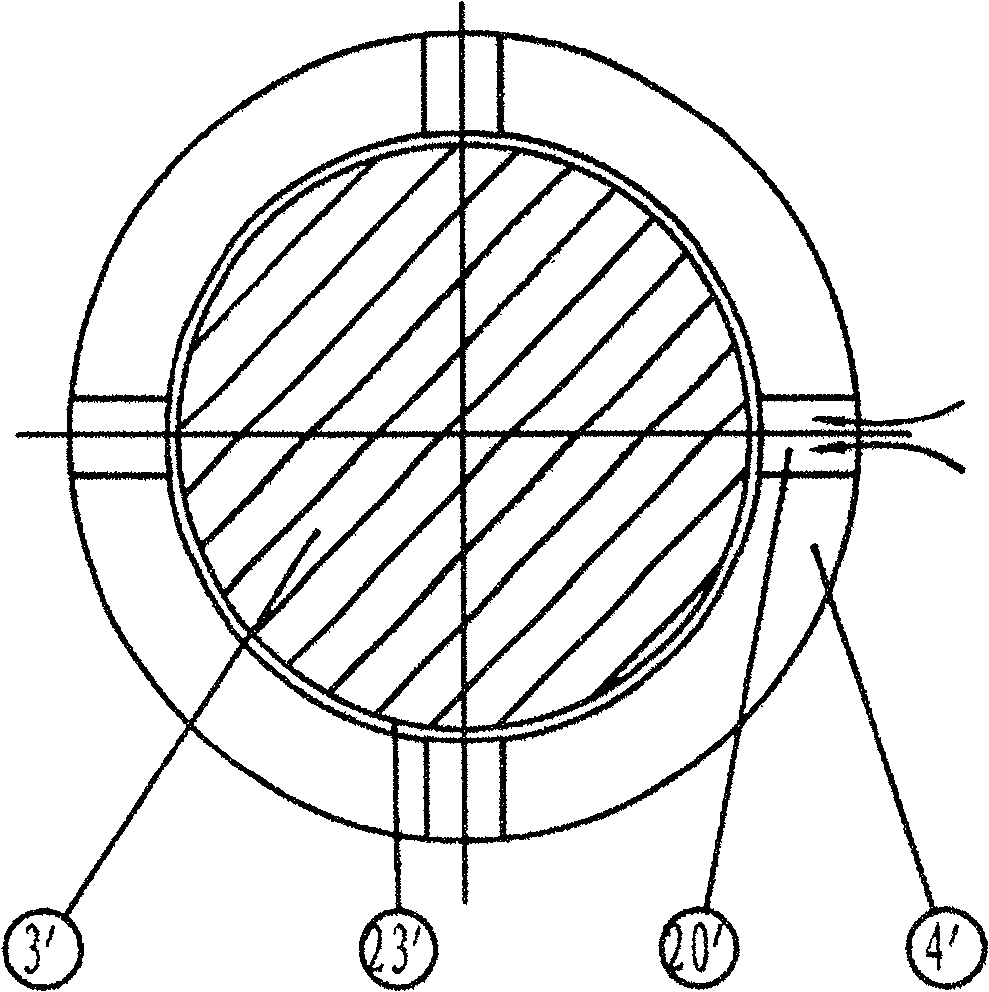

[0030] See first Figure 4 The structure diagram of the present invention shows that the shaft seal device of the open air conditioner compressor is arranged between the cylinder block 1, the crankshaft 2 and the front cover 10 of the compressor, and it includes a shaft seal 01, a thrust ring 3, a compression spring 4, Lip seal ring 11, oil drain passage 17, oil return evaporation chamber 19, breathing hole 20, main oil passage 22, oil inlet passage 12 and return hole 21. The front cover 10 is hermetically fixed on the end of the cylinder block 1 , the crankshaft 2 runs through the cylinder block 1 and is supported on the front cover 10 . The shaft seal 01 includes a shaft seal shell 5, a shaft seal shell screw 6, a baffle plate 7, a dynamic ring seal ring 8, a dynamic ring 9, a static ring 13, a static ring seal ring 14 and several thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com