Spray atomizer for fine coal slurry fuel

A spray atomization and coal slurry technology, applied in the direction of fuel injection devices, injection devices, liquid injection devices, etc., can solve the problems of increased movement resistance of nozzle parts, damage to lubrication, inability to complete fuel injection, atomization, etc., to achieve expansion The effect of the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

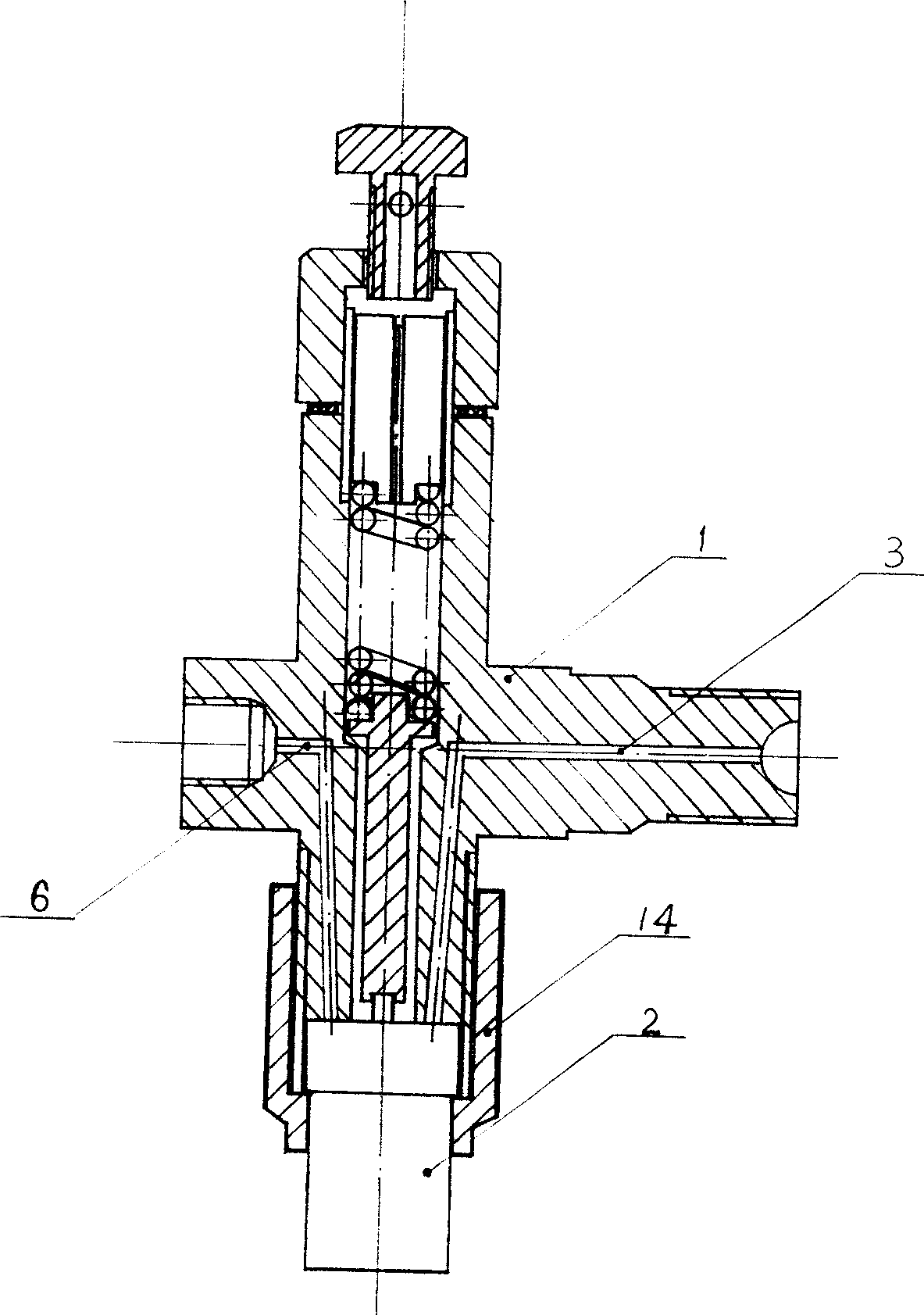

[0035] figure 1 Schematic diagram of a jet atomizer for a swirl chamber diesel engine fueled with fine coal slurry. It consists of a sprayer body 1 and a spray nozzle pair 2, which are positioned by a locator and then screwed and fixed by a screw cap 14.

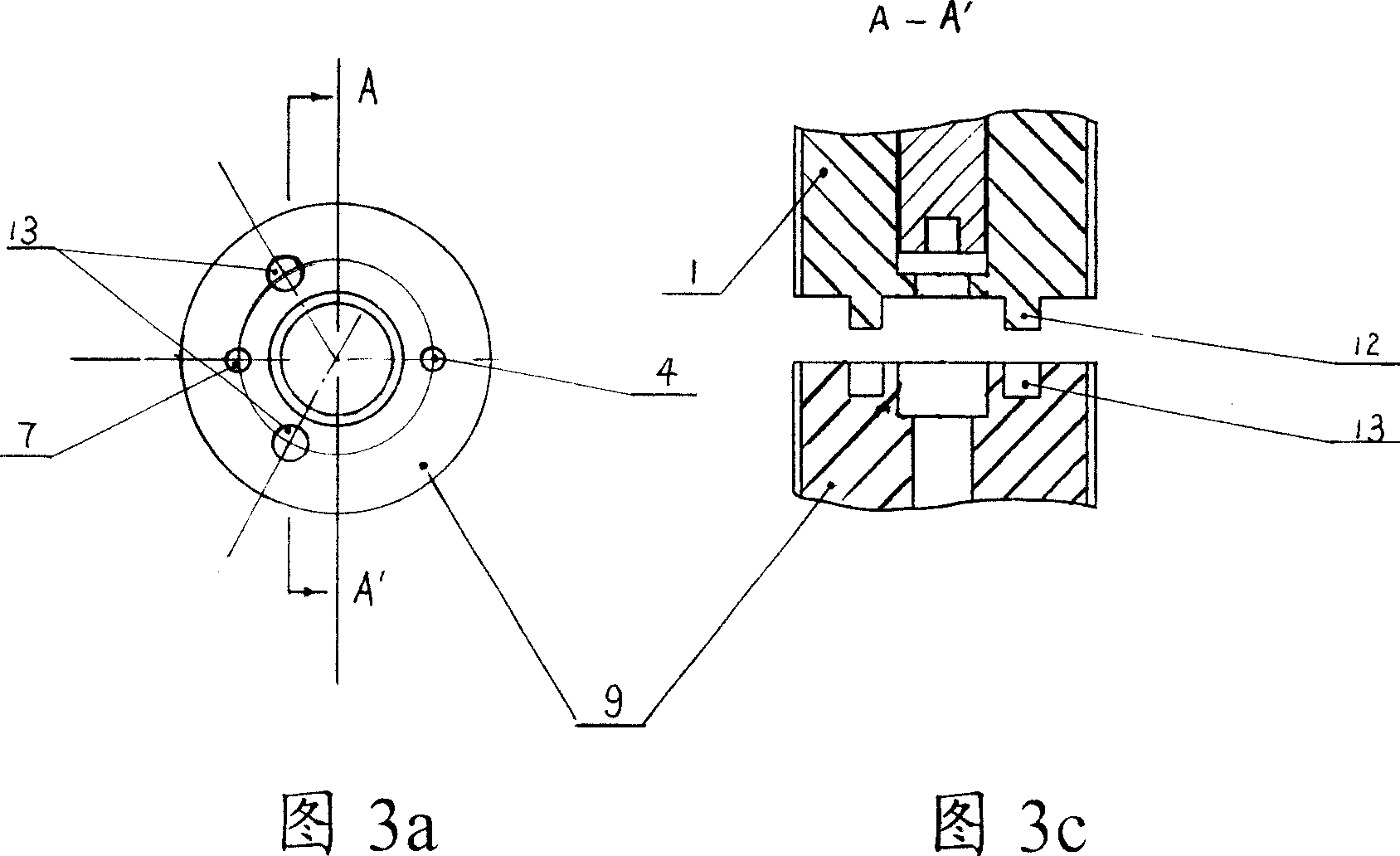

[0036] The locator is composed of a locating pin 12 and a locating hole 13 (refer to FIG. 3 ). The slurry supply channel 3 and the oil supply channel 6 are opened in the sprayer body 1, and the positions of the slurry supply channel 3 and the oil supply channel 6 are opposite, as long as the coal slurry fuel is not mixed with the lubricating diesel oil and can be installed .

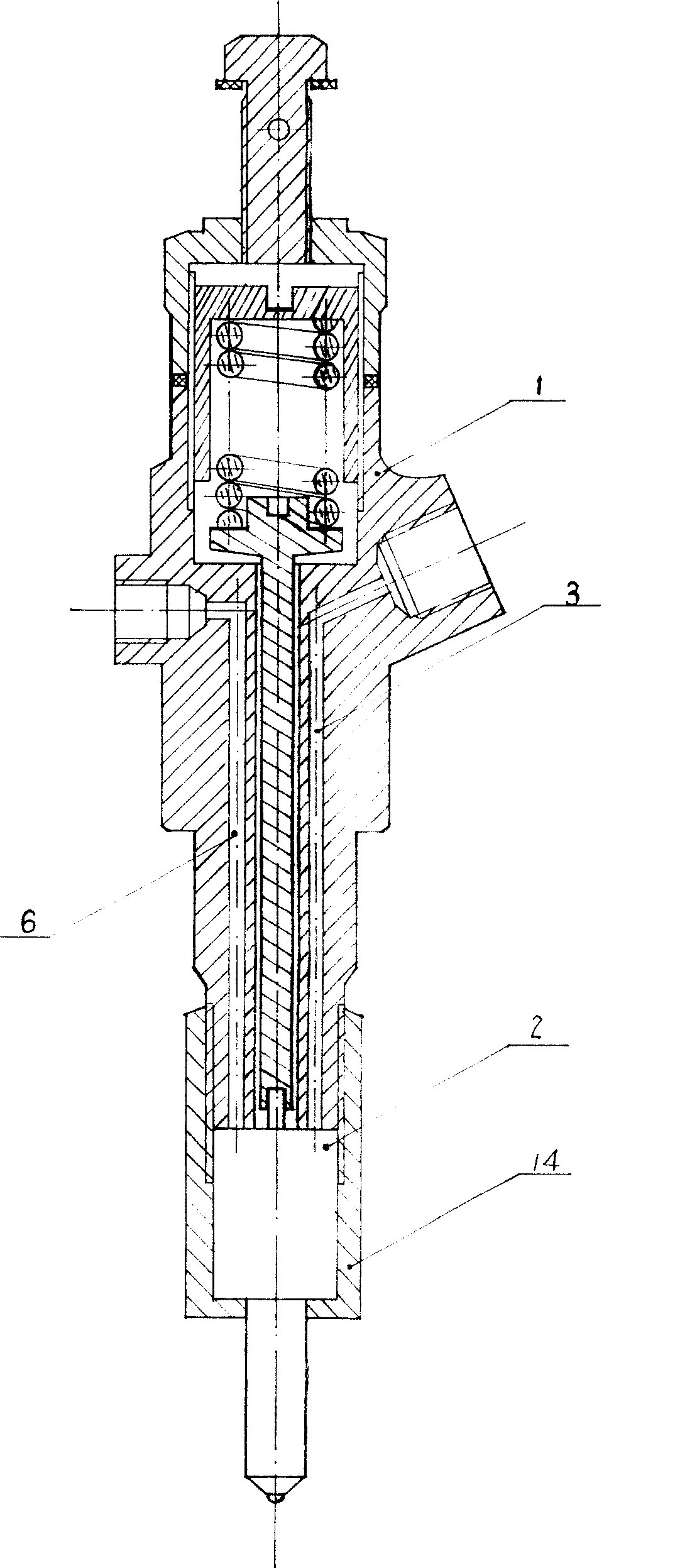

[0037] figure 2 Schematic of a jet atomizer for a direct injection diesel engine fueled with fine coal slurry. It consists of a sprayer body 1 and a spray nozzle pair 2, which are positioned by a locator and then screwed and fixed by a screw cap 14. The locator is composed of a locating pin 12 and a locating hole 13 (refer to FIG. 4 ). The slurr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap