Transporting platform and transporting unit

一种运输平台、横梁的技术,应用在堆码定位的器具领域,能够解决相邻角件间距不符合、降低运输安全性、集装箱只能跳装等问题,达到便于存储、结构简单、降低储运成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

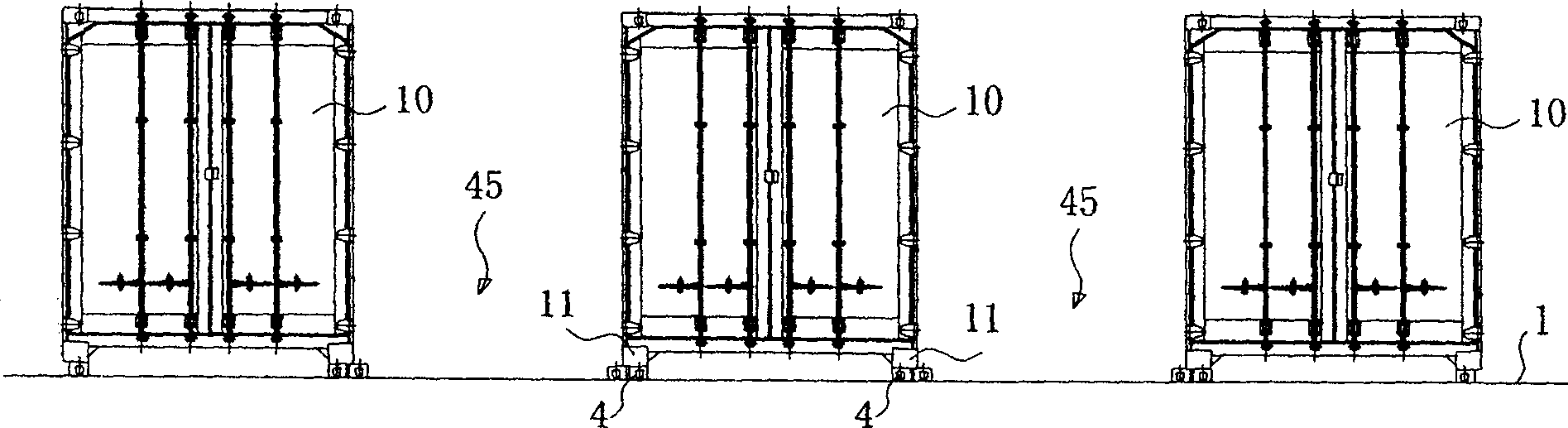

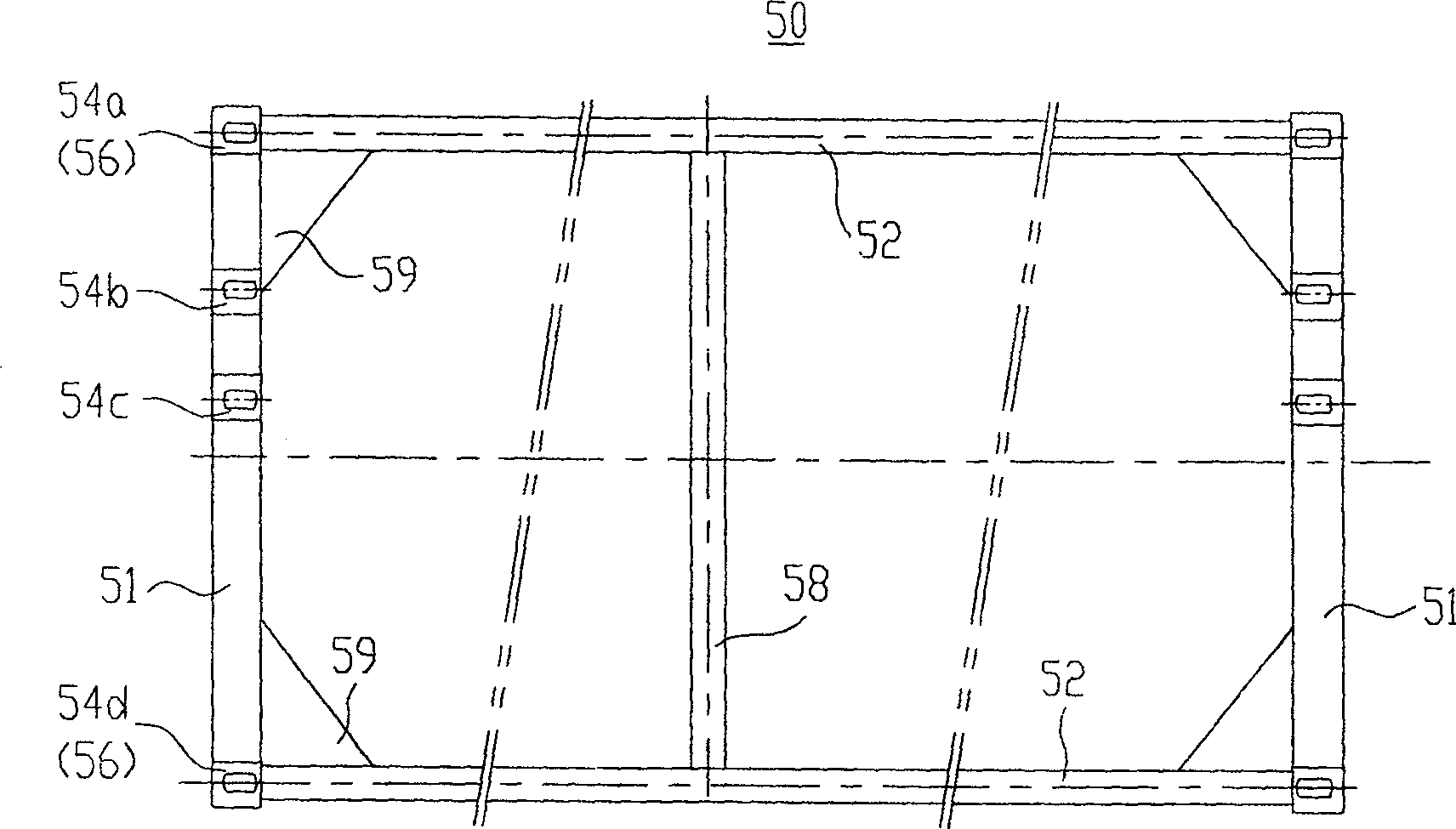

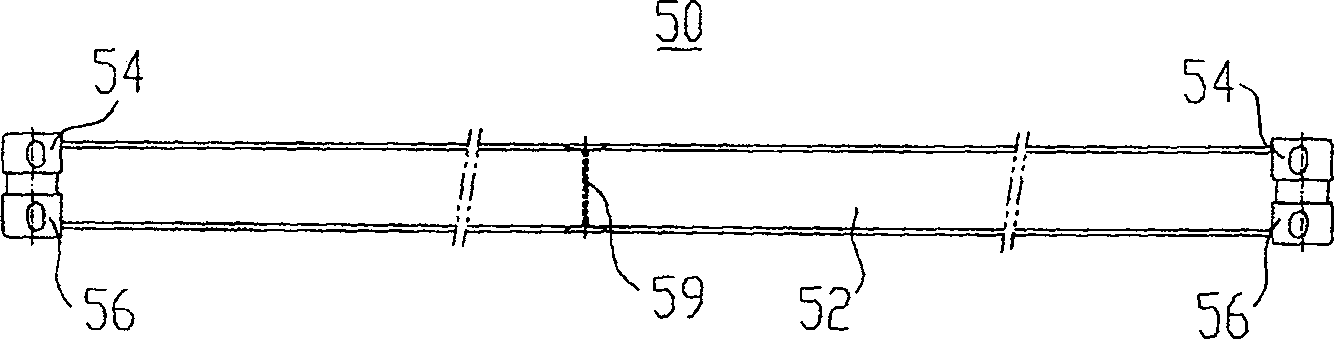

[0029] Such as Figure 2A ~ Figure 2C As shown, the transport platform 50 of the present invention includes a pair of beams 51 and a pair of longitudinal beams 52 connected between the pair of beams. The beam 51 and the longitudinal beam 52 constitute the main frame structure of the transport platform of the present invention. One or more reinforcements may also be provided between the beams 51 and / or the longitudinal beams 52 to improve the overall strength of the transport platform 50 . For example, a reinforcing plate 58 may be provided between adjacent beams 51 and longitudinal beams 52, a reinforcing beam 59 may be provided between opposite longitudinal beams 52, and so on.

[0030] A pair of bottom corner fittings 56 are arranged at the bottom of each beam 51, and the center distance between them is adapted to the center distance of the corner fittings in the width direction of the ISO standard container. And the center-to-center distance of the adjacent bottom corner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com