PPR plastic permanent magnet cut off valve

A globe valve, plastic technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of increased engineering cost, inability to adjust the flow, loose metal inserts, etc., to overcome the high manufacturing cost, easy installation, maintenance, adjustment, etc. The effect of traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

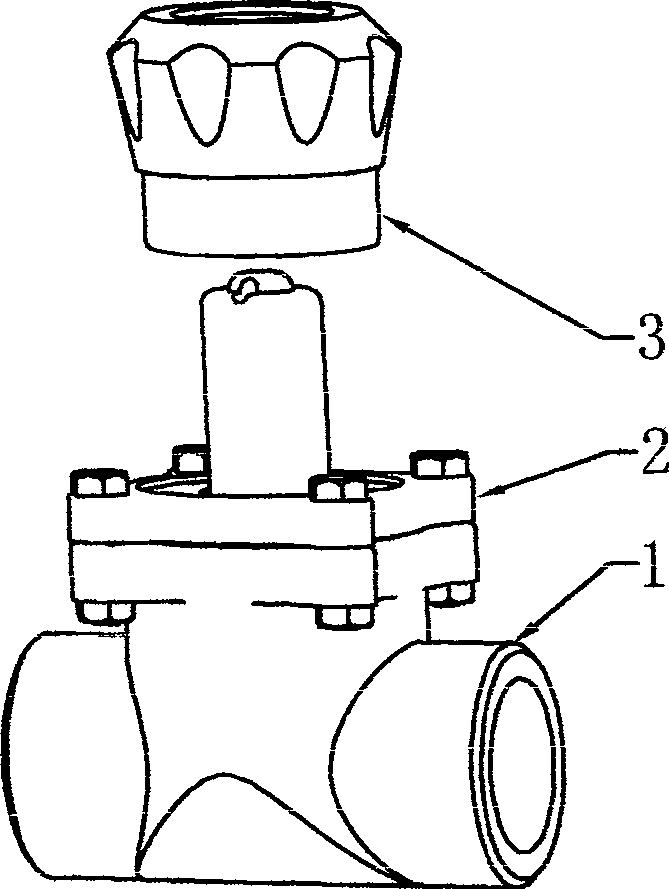

[0012] according to figure 1 As shown, the valve seat 1 made of one-time injection of PPR material and the valve cover 2 made of one-time injection of POM material are connected by flanges and bolts, and the operating handle 3 and the internal structure of the valve still use the known Permanent magnet stop valve (ZL02279055.1) technology, the water inlet and outlet of valve seat 1 and the PPR pipe are connected by hot melt.

Embodiment 2

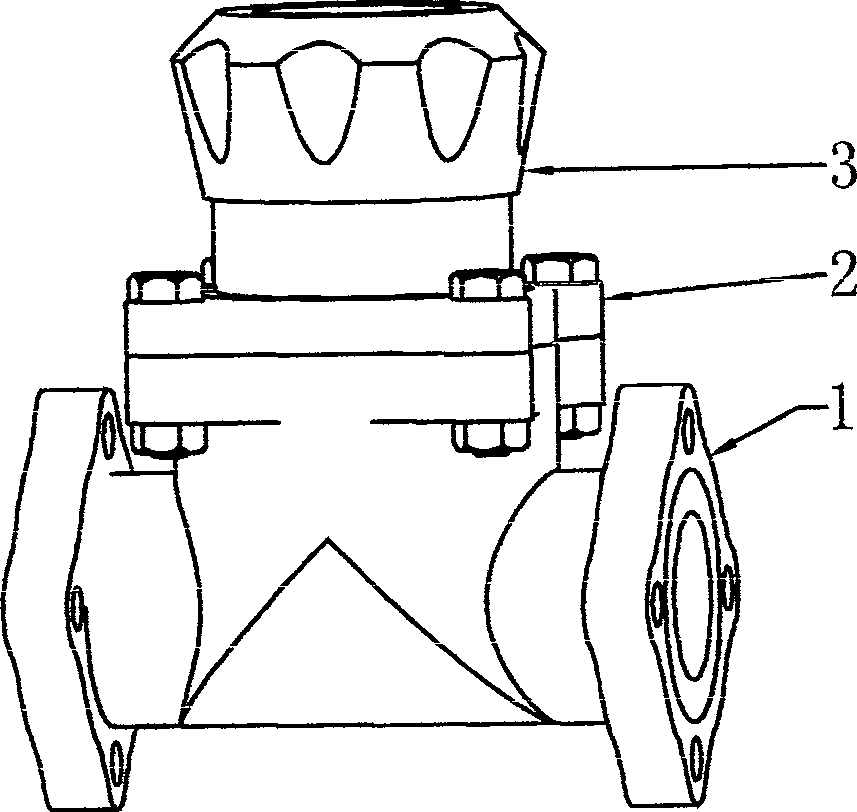

[0014] according to figure 2 As shown, the valve seat (1) made of one-time injection of PPR material and the valve cover 2 made of one-time injection of POM material are connected by flanges and bolts, and the operating handle 3 and the internal structure of the valve are still used. The well-known permanent magnet stop valve (ZL02279055.1) technology, the inlet and outlet of the valve seat 1 and the non-PPR material pipeline are connected by flanges and bolts.

Embodiment 3

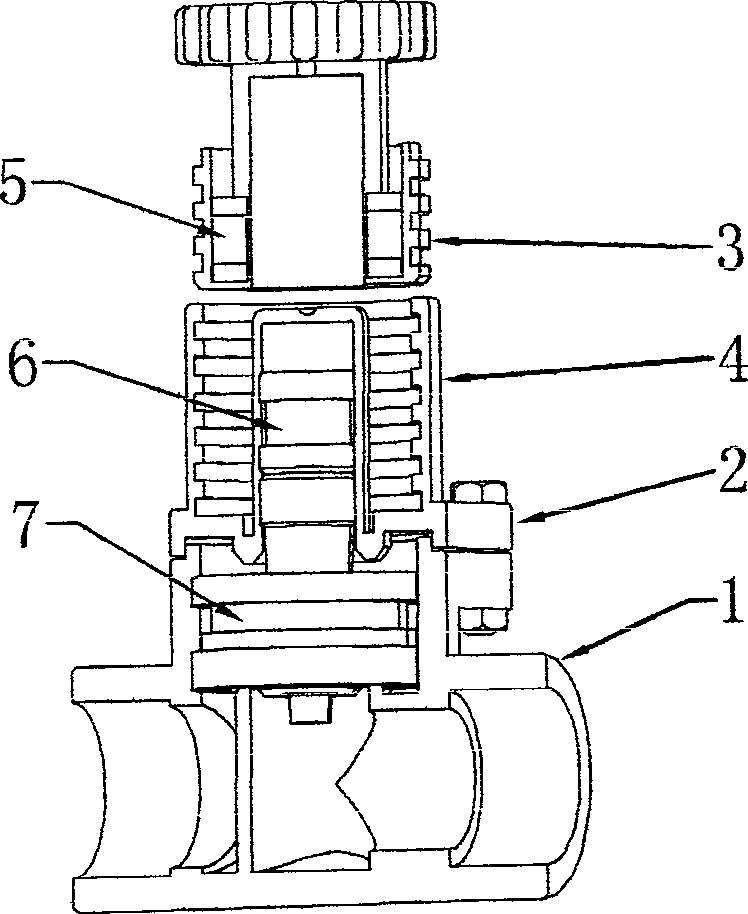

[0016] according to image 3 As shown, the valve seat 1 made of one-time injection of PPR material and the valve cover 2 made of one-time injection of POM material are connected by flanges and bolts. figure 1 , figure 2 The difference is: a peripheral guide sleeve 4 with internal threads is added to the bonnet 2, external threads are added to the outside of the operating handle 3, the operating handle 3 and the peripheral guide sleeve 4 form a threaded connection, and the operating handle 3 can be rotated forward and reverse. Make the permanent magnet 5 move up and down and stay in any position, so as to control the armature in the valve to stay in different positions, so that the valve can control different flow rates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com