Exposure device and device manufacturing method

A technology of exposure device and optical element, which is applied in semiconductor/solid-state device manufacturing, photolithography process exposure device, microlithography exposure equipment, etc. Malfunction or deterioration of exposure accuracy and measurement accuracy, and the effect of preventing deterioration of exposure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

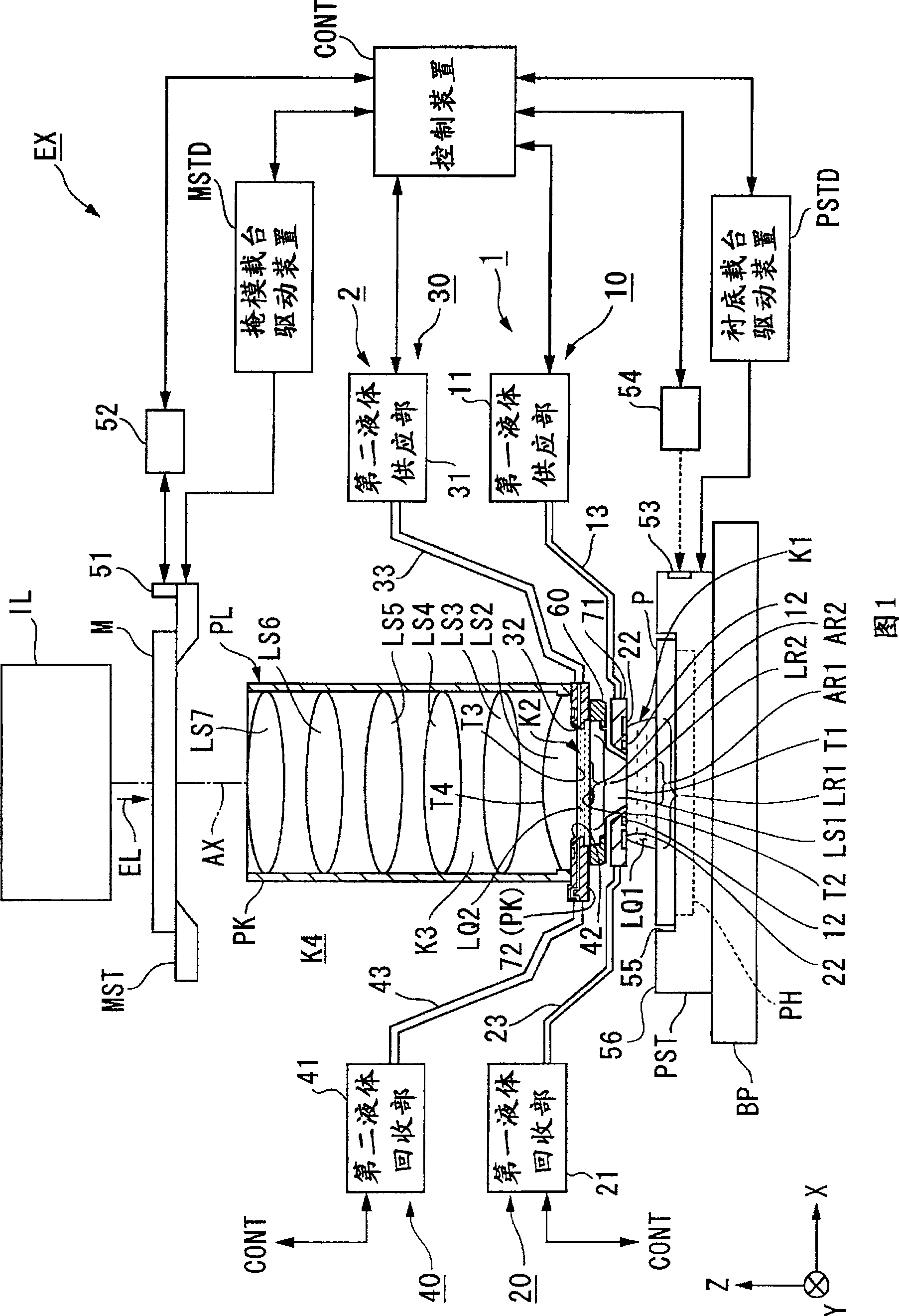

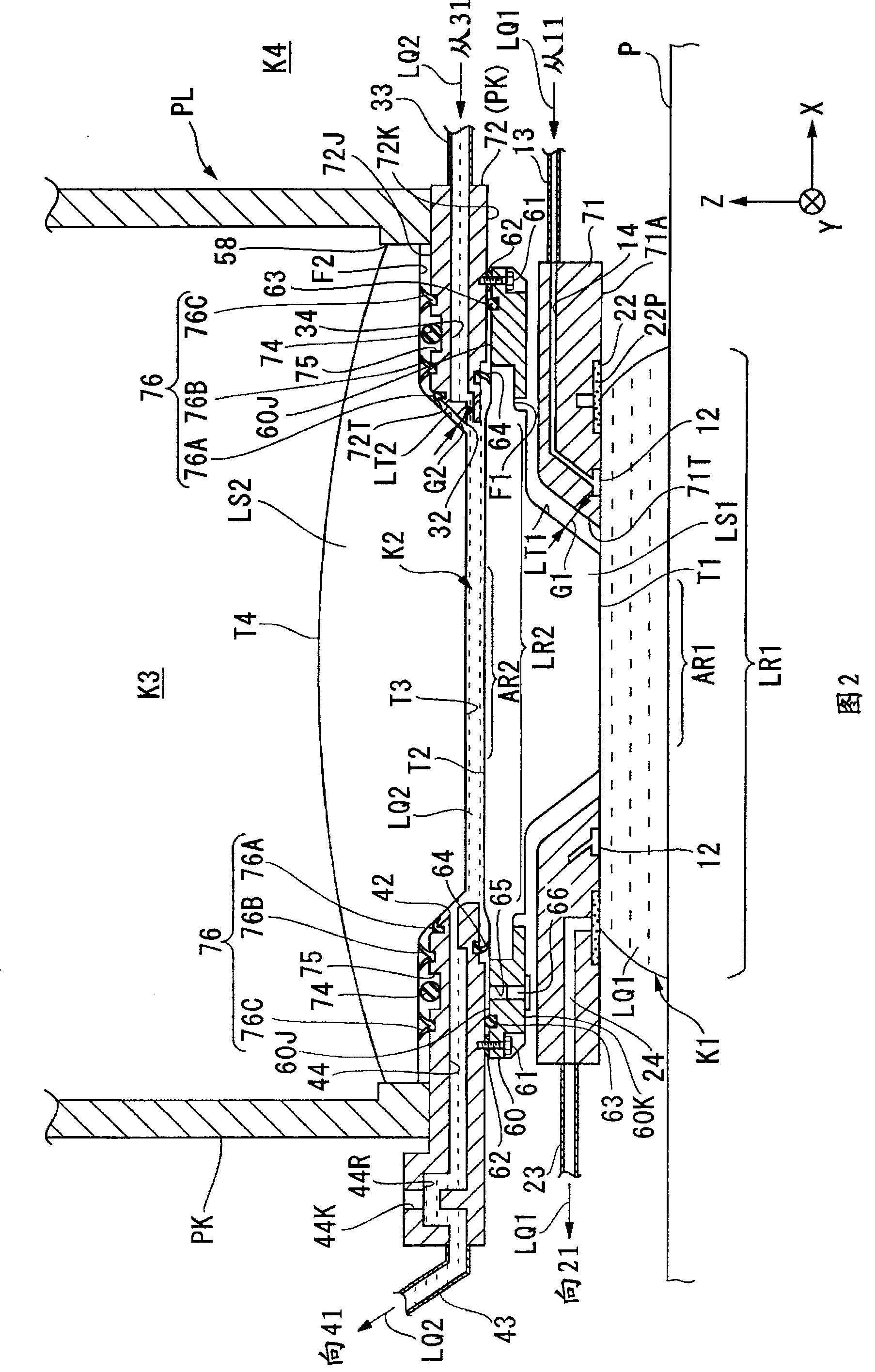

[0067] FIG. 1 is a schematic configuration diagram showing an exposure apparatus EX according to a first embodiment. In FIG. 1 , the exposure apparatus EX includes: a movable mask stage MST that holds a mask M; a substrate stage PST that includes a substrate holder PH that holds a substrate P; and a mask to be held by the mask stage MST. Illumination optical system IL for illuminating M with exposure light EL; projection optical system PL for projecting and exposing a pattern image of mask M illuminated by exposure light EL onto substrate P held by substrate stage PST; collectively controlling exposure A control device CONT for the overall operation of the device EX.

[0068] The exposure apparatus main body EX of the present embodiment is a liquid immersion exposure apparatus to which a liquid immersion method is applied in order to substantially shorten the exposure wavelength to improve the resolution, and to substantially increase the depth of focus. The first liquid imme...

no. 2 approach

[0144] Next, as a second embodiment, the procedure for replacing the first optical element LS1 will be described.

[0145] In the first liquid LQ1 of the first liquid immersion region LR1 (the first space K1), foreign matters caused by, for example, a photosensitive agent (photoresist), impurities etc. generated from the substrate P, etc. are mixed, so there is This first liquid LQ1 may be contaminated. Since the first liquid LQ1 in the first liquid immersion region LR1 is also in contact with the bottom surface T1 of the first optical element LS1 , the contaminated first liquid LQ1 may contaminate the bottom surface T1 of the first optical element LS1 . In addition, impurities suspended in the air may also adhere to the bottom surface T1 of the first optical element LS1 exposed on the image plane side of the projection optical system PL. Therefore, the contaminated first optical element LS1 is replaced at the prescribed time.

[0146] Before replacing the first optical elem...

no. 3 approach

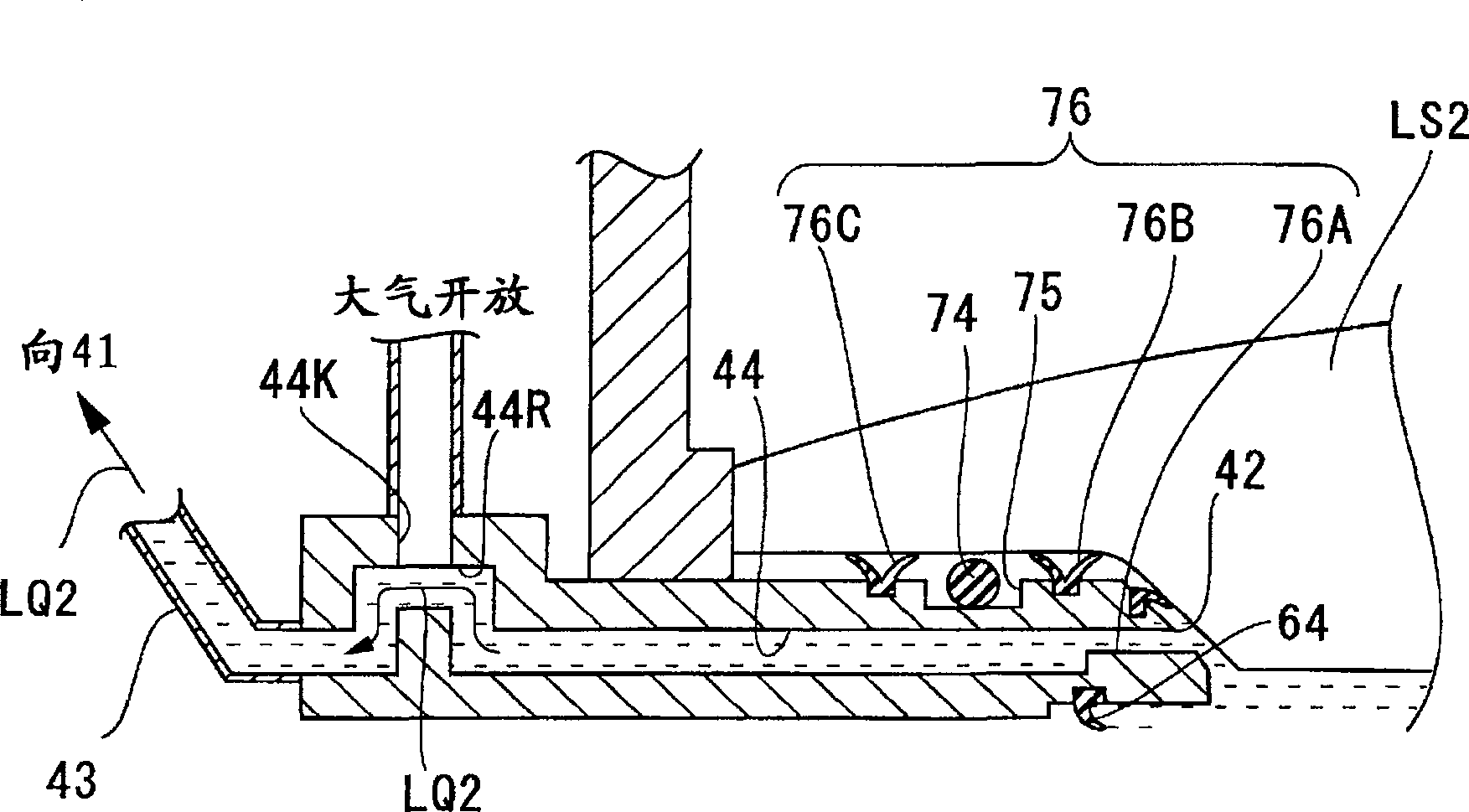

[0155] Below, refer to Figure 18 A third embodiment will be described. A characteristic part of this embodiment is that the second nozzle member 72 vacuum-adsorbs and holds the first optical element LS1 . Figure 18 Among them, the second nozzle member 72 includes a holding portion 100 for holding the first optical element LS1 by vacuum suction. The holding portion 100 is provided on the bottom surface 72K of the second nozzle member 72 opposite to the top surface T2 of the first optical element LS1 . The bottom surface 72K of the second nozzle member 72 faces a region different from the region through which the exposure light EL passes of the top surface T2 of the first optical element LS1. The holding portion 100 includes a vacuum suction groove 101 annularly formed on the bottom surface 72K of the second nozzle member 72 . In a part of the vacuum suction tank 101, suction holes connected to a vacuum system not shown are formed. By driving the vacuum system with the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com