Construction method and construction technique for wide cross section beam formwork supporting system

A support system and construction method technology, applied in the preparation of pillars and building components on site, construction, etc., can solve the problems of long occupation time, poor economic benefits, and more turnover materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

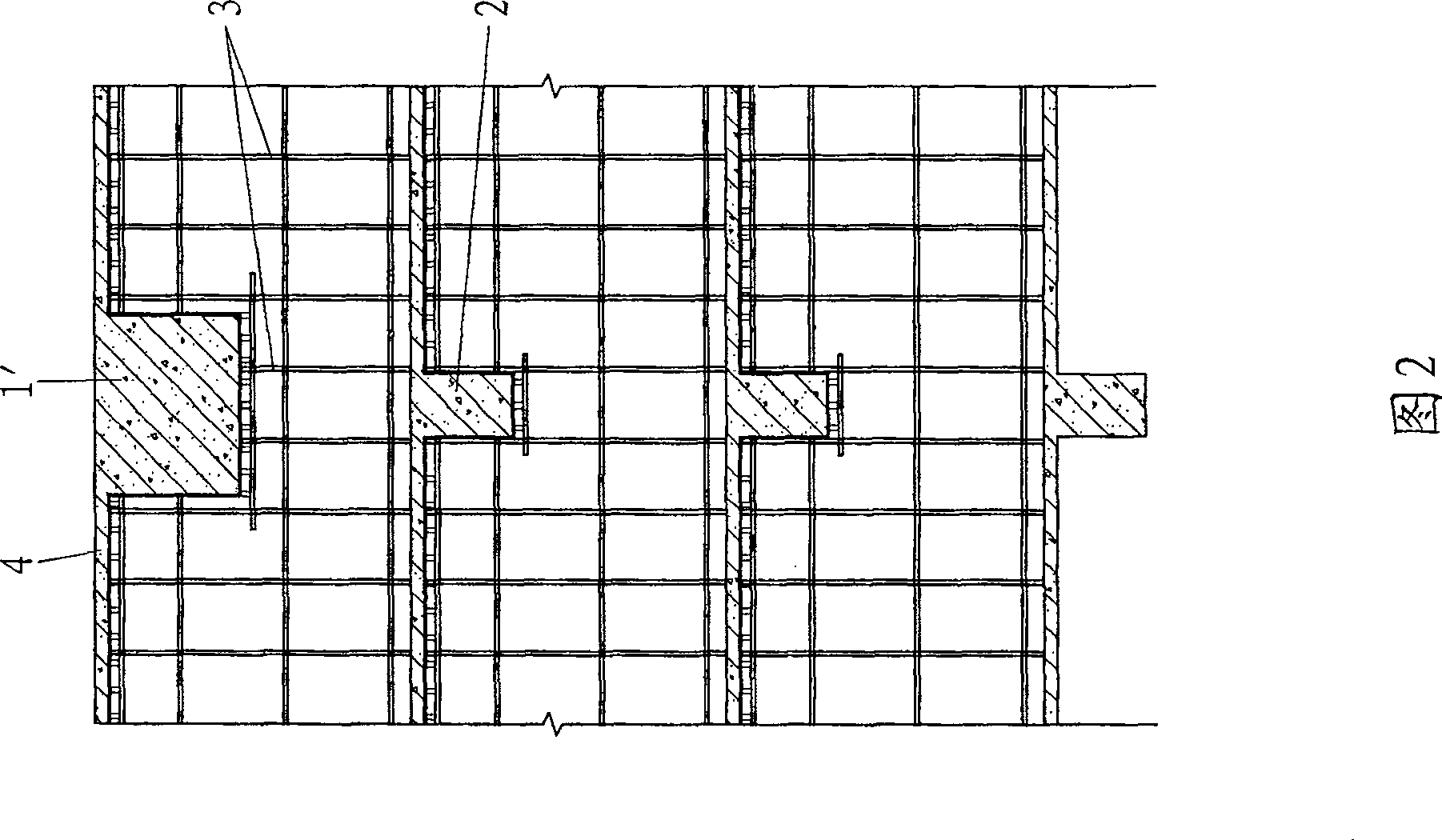

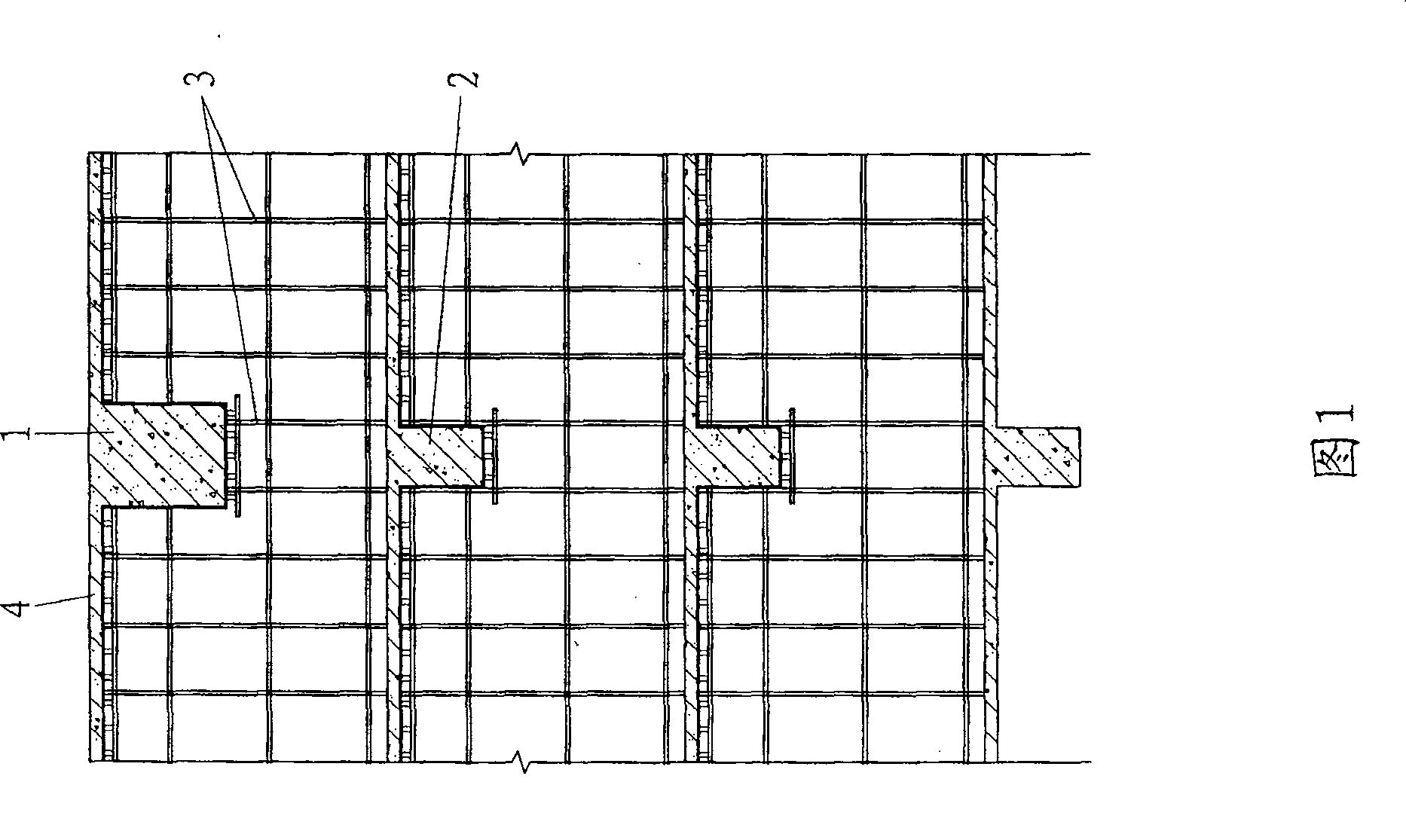

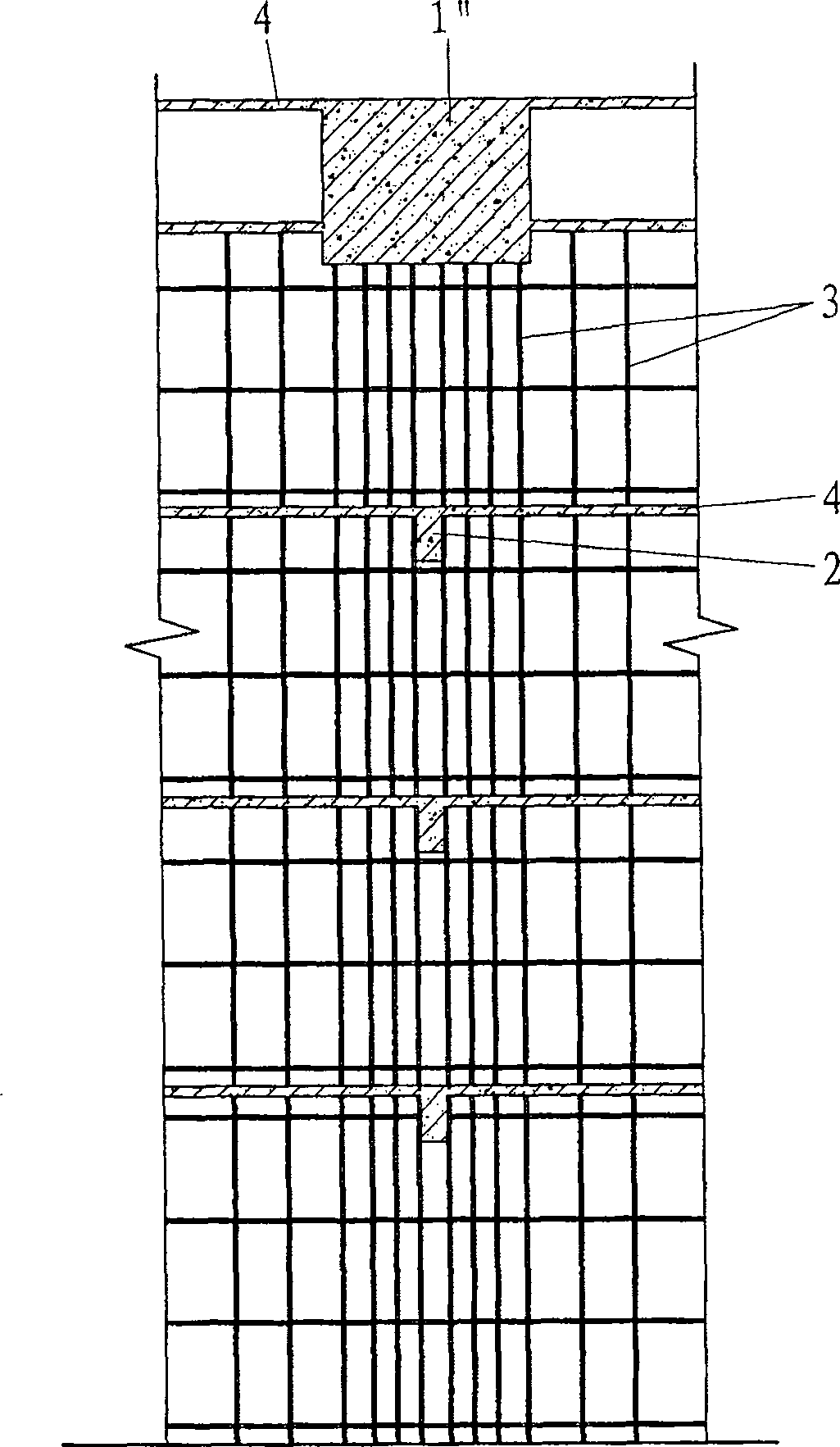

[0025] What the present invention relates to is a kind of reinforced concrete structure, self-weight is relatively large, and the ratio of the section width of the frame beam of the lower layer is more than twice, and the support system of the frame support beam formwork corresponding to the position of the frame beam of the lower layer is:

[0026] 1. The formwork supported by "V" is used to transfer the self-weight and construction load of the frame support beam to the lower structure in an organized way through the inclined vertical rod, and the lower frame beam at the corresponding position is independently borne to fully utilize the frame. beam bearing capacity.

[0027] 2. When the bearing capacity of the lower frame beam is insufficient, the insufficient part can be supplemented by pre-enlarging the section of the frame beam or / and adding reinforcement to meet the bearing capacity requirements.

[0028] Specifically, as shown in Figures 4 and 5, in the transfer layer A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com