High energy vacuum CROWBAR switch based on high permitivity planar flashover

A technology of surface flashover and vacuum, applied in the field of CROWBAR switch, to achieve the effect of small discharge delay and jitter, large current capacity, and enhanced working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

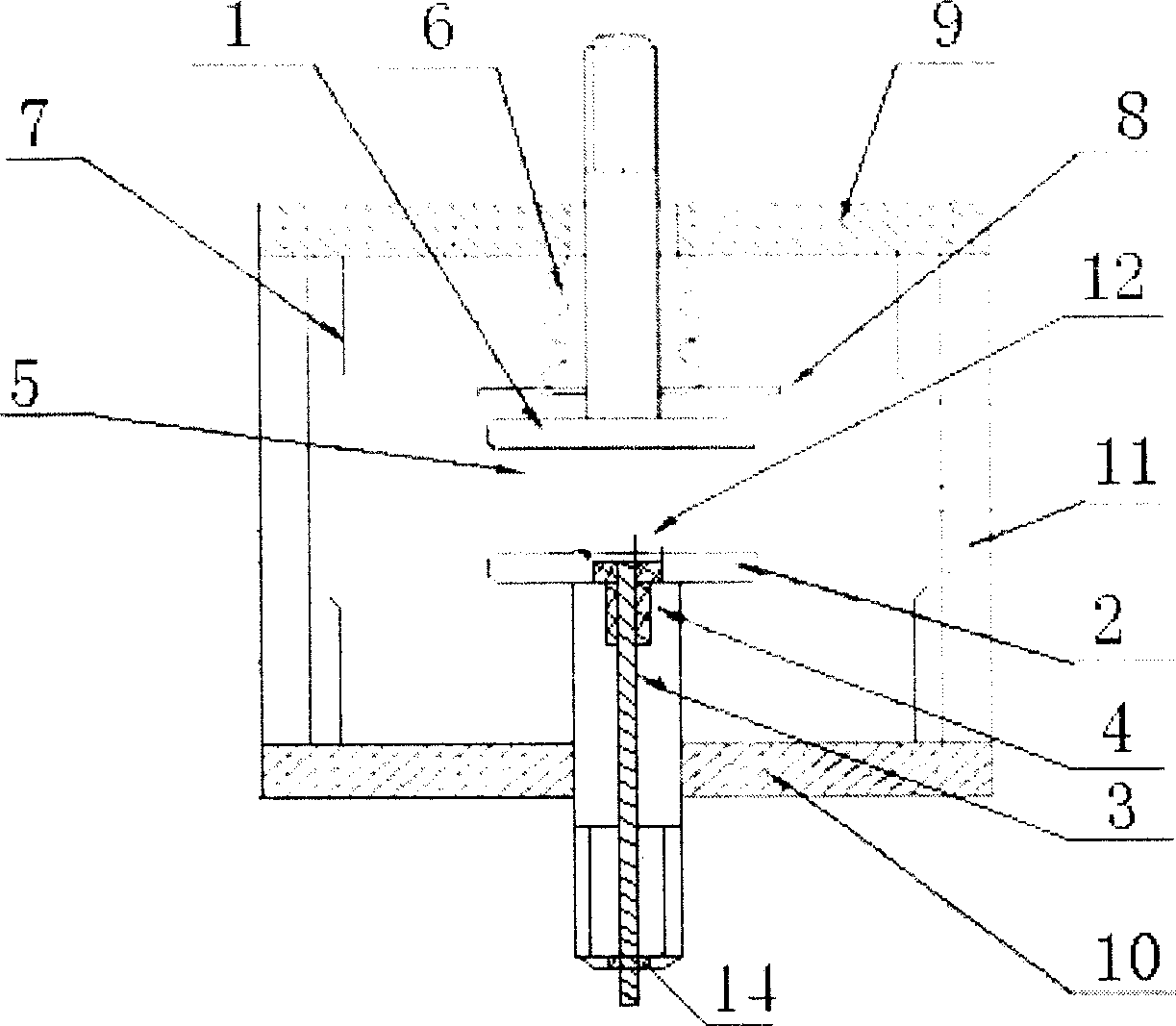

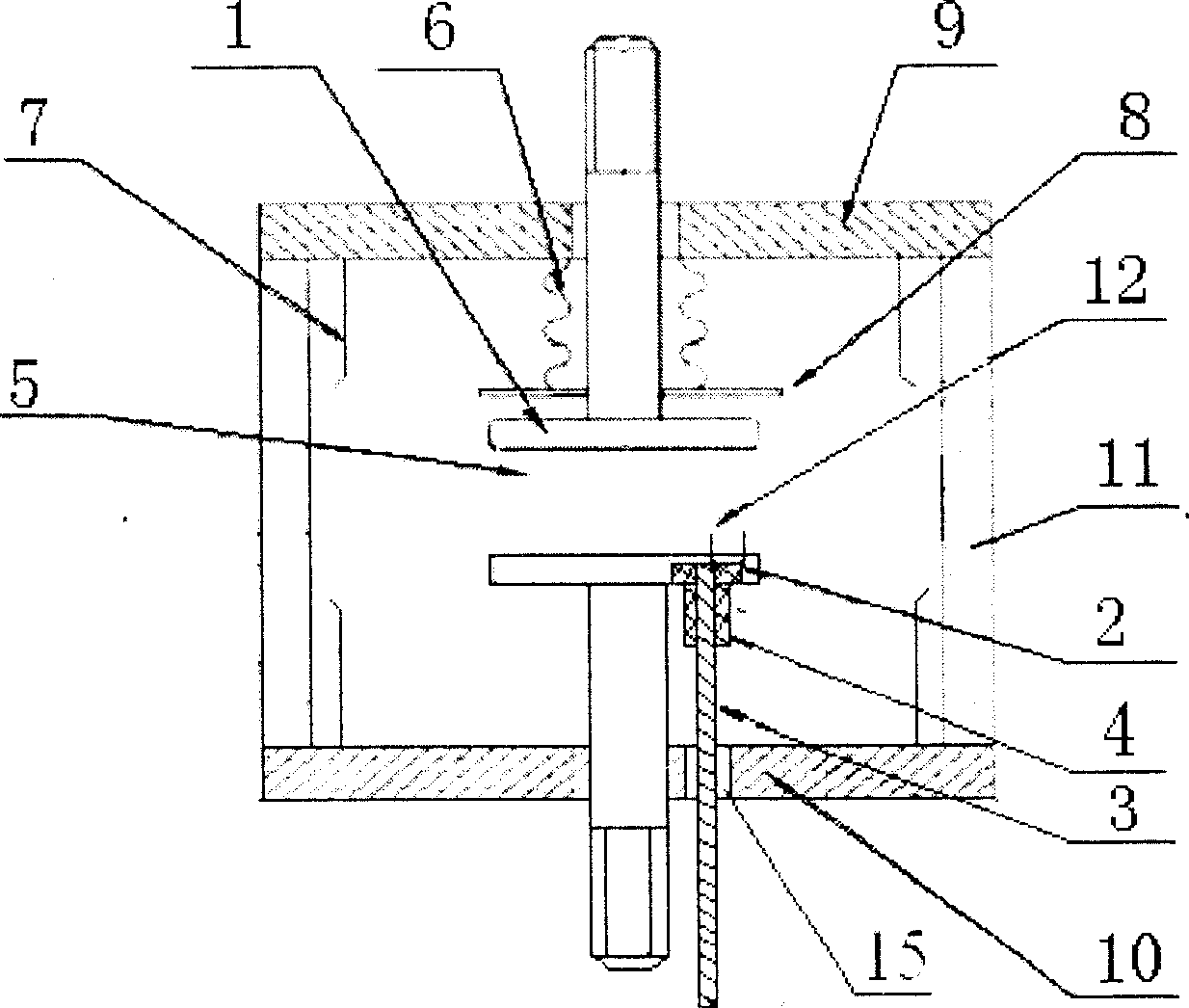

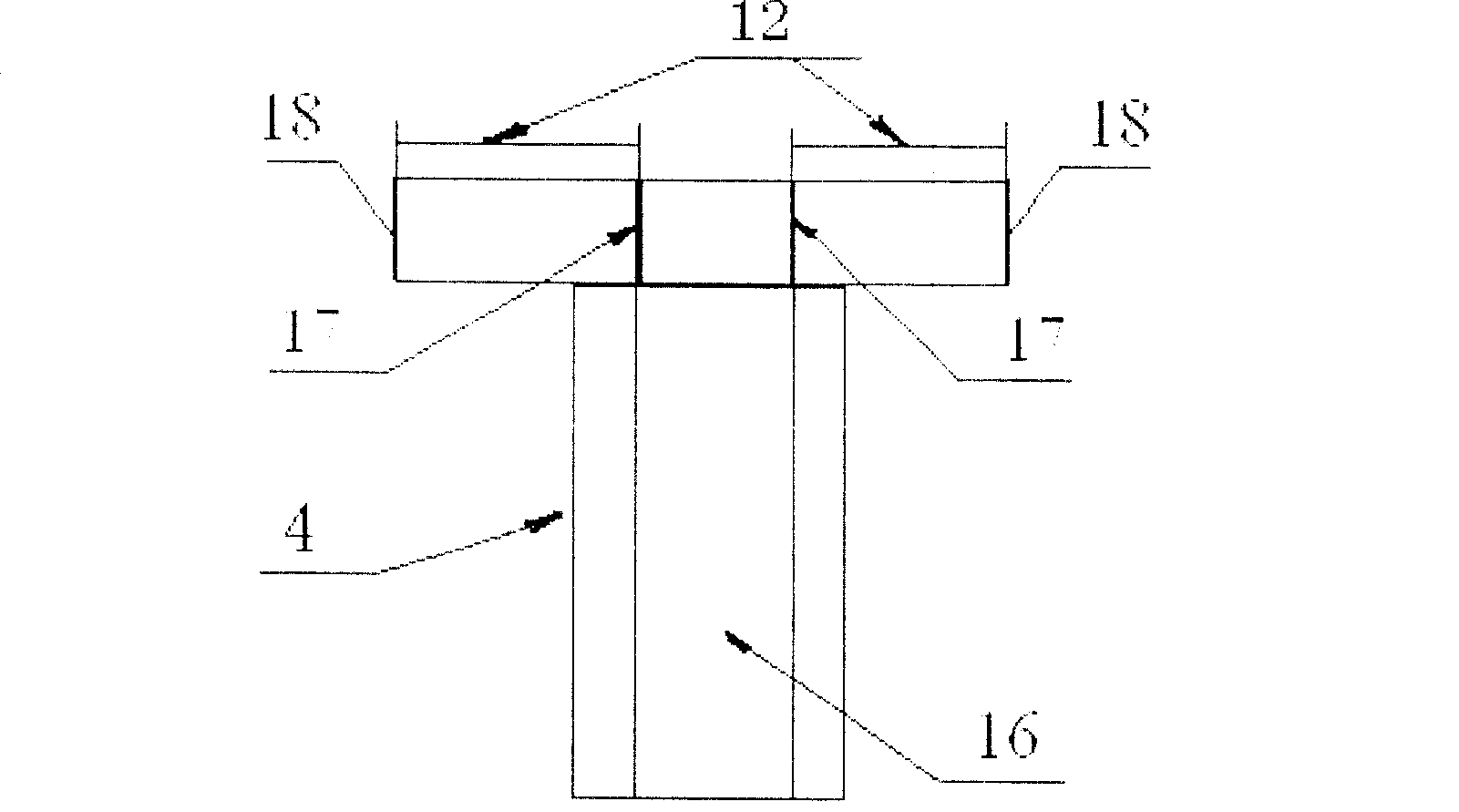

[0014] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] see figure 1 , Embodiment 1, this embodiment includes an insulating casing 11 and an upper electrode 1 and a lower electrode 2 arranged in the insulating casing 11, a main discharge gap 5 is formed between the upper electrode 1 and the lower electrode 2, and the upper electrode 1 and the lower electrode The electrode 2 is set in the insulating shell 11 through the upper end flange 9 and the lower end flange 10, and the pressure in the airtight shell formed by the insulating shell 11 and the upper and lower end flanges 9, 10 arranged at both ends of the insulating shell 11 for 10 -2 ~10 -5 Pa, the upper electrode 1 is a movable electrode, and the lower electrode 2 is a fixed electrode. In the lower electrode 2, there is a creeping flashover dielectric material 4 embedded with a columnar trigger electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com