Heating device

A technology of heating device and object to be heated, applied in lighting and heating equipment, electrography, optics, etc., can solve the problems of thermal deformation of resin layer 3, incorrect mechanical dimensions, deviation of heating temperature, etc., so as to improve heating stability. performance, improve production efficiency, and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Hereinafter, the embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the following embodiments, although various limitations are made to the constituent elements, types, combinations, shapes, relative arrangements, etc., these are merely examples, and the present invention is not intended to limited to this.

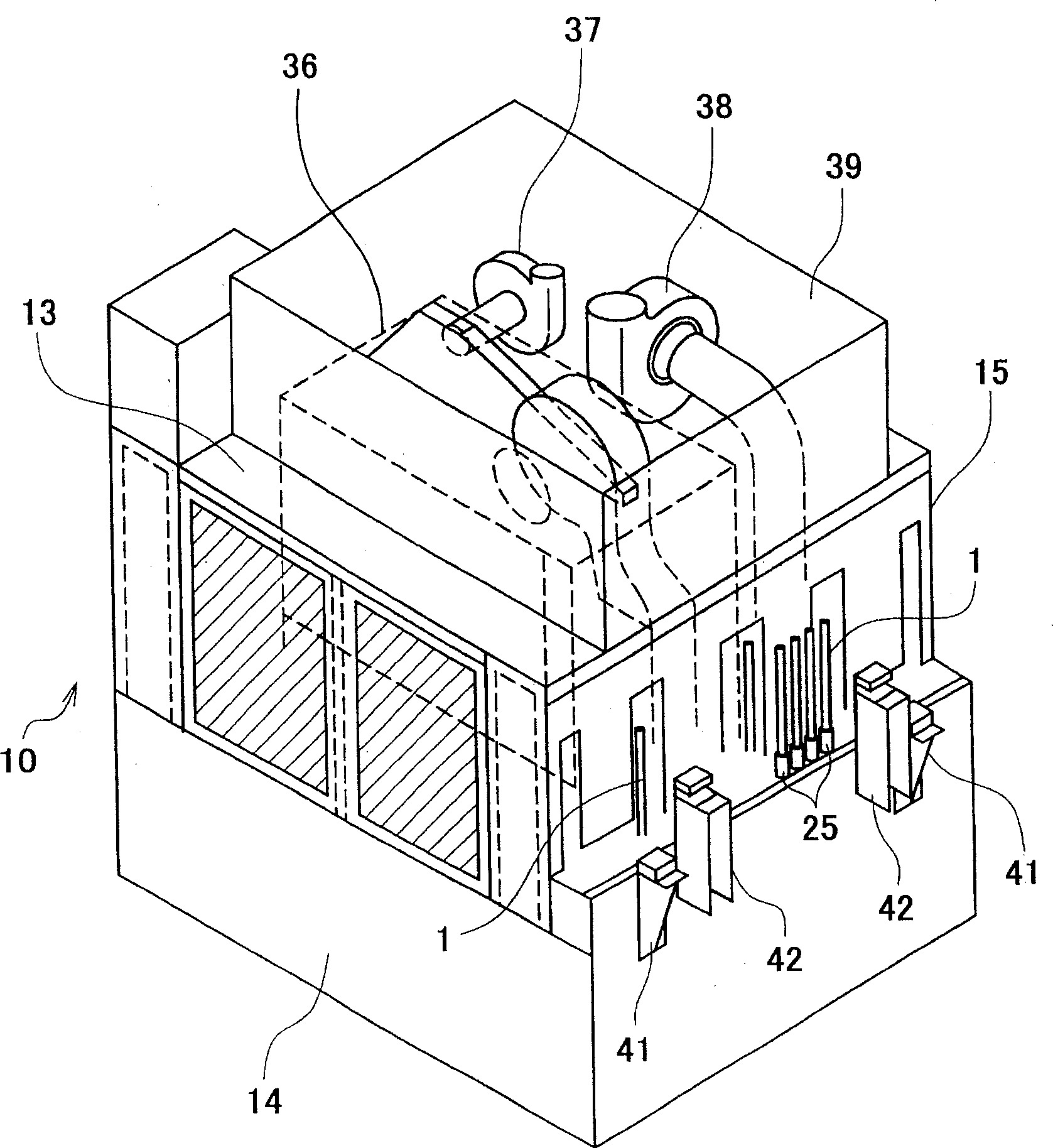

[0067] image 3 is a schematic appearance diagram of the heating device according to the present invention, in image 3 Among them, 10 represents the device body, and the device body 10 is as Figure 4 , Figure 5 As shown, a lower loading plate 11, an intermediate loading plate 12, and an upper loading plate 13 are provided.

[0068] Between the lower loading plate 11 and the middle loading plate 12, a cover plate 14 is provided to cover these loading plates from the side, and between the middle loading plate 12 and the upper loading plate 13, a cover plate 14 is provided to cover these loading plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com