Starch-contained biodegradable material and its preparation method

A technology for degrading materials and starch, which can be used in sustainable manufacturing/processing, climate sustainability, sustainable packaging, etc., and can solve problems such as degradation of mechanical properties of materials and changes in starch content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Raw material ratio (parts by weight):

[0032] 20 parts polypropylene

[0033] Starch 30 parts

[0034] 1.5 parts of isopropanol

[0035] Silane coupling agent 0.5 part

[0036] Calcium stearate 0.05 parts

[0037] Mix polypropylene and calcium stearate, heat to 230-250°C, and send it to the supply box connected to nozzle 1; mix starch, isopropanol, silane coupling agent (vinyltriethylsilane) 75-85 ℃ for about 10 minutes, after being ground by a high-speed mixer, put it into the supply box connected to the shower head 2.

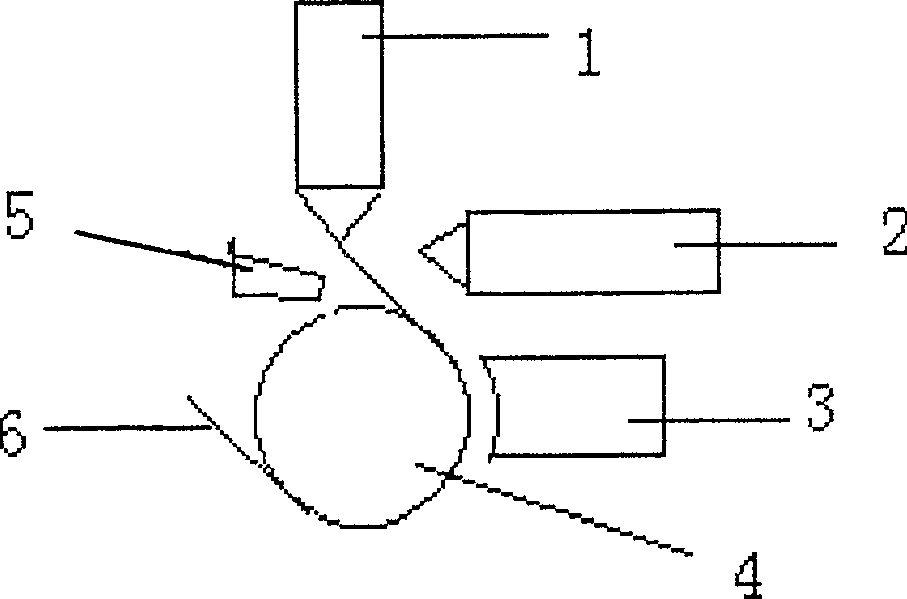

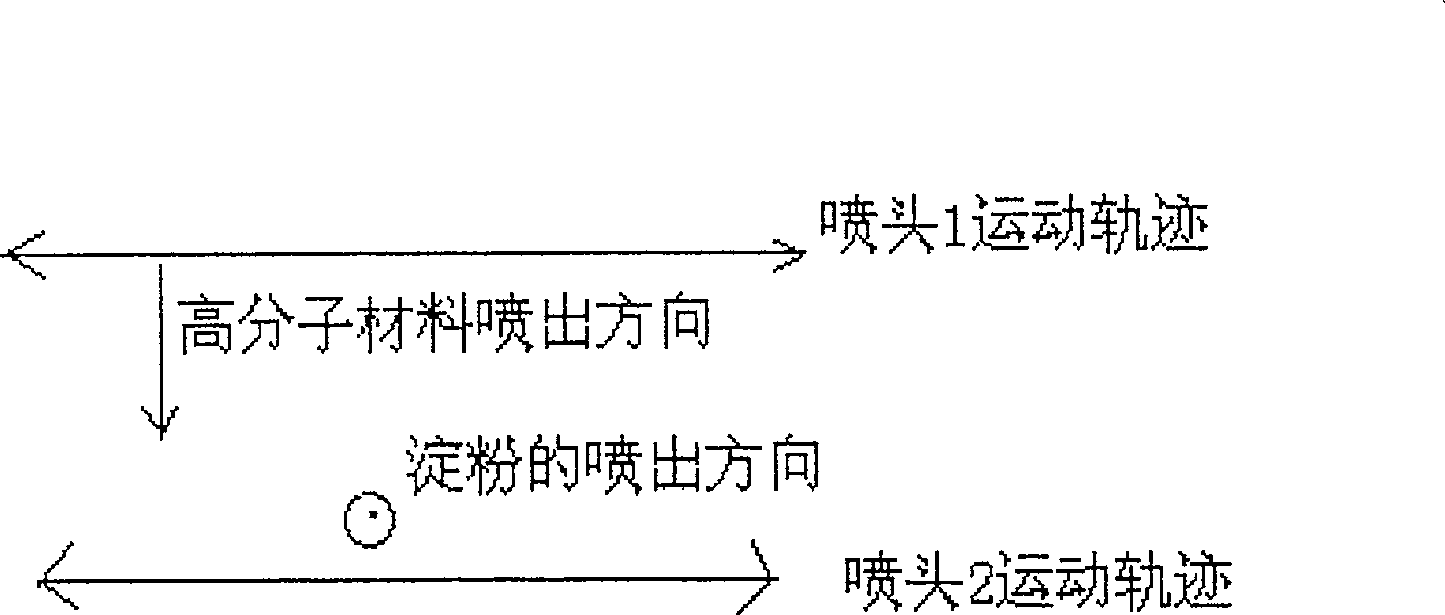

[0038] like figure 1 As shown, the first sprinkler system includes the nozzle 1, the feed box and the control mechanism, and the second sprinkler system includes the nozzle 2, the feed box and the control mechanism, so that the nozzle 1 and the nozzle 2 are arranged in a substantially perpendicular state (Fig. The middle "⊙" indicates that the direction is perpendicular to the surface of the paper, and the materials therein are sprayed on the surf...

Embodiment 2

[0043] Raw material ratio (parts by weight):

[0044] 20 parts polypropylene

[0045] Starch 35 parts

[0046] 1.5 parts of isopropanol

[0047] Silane coupling agent 1.0 parts

[0048] Calcium stearate 0.1 parts

[0049] Mix starch, isopropanol, and silane coupling agent (vinyl trichlorosilane) at 75-85°C for about 10 minutes, grind them and put them into the supply box connected to sprinkler 2; polypropylene and calcium stearate After mixing, it is heated to about 230-250°C and enters the supply box connected to sprinkler 1.

[0050] The setting and operation of spraying system are identical with embodiment 1, make the ejection speed of starch: the ejection speed of polypropylene=7:4, the temperature of cooling roll is about 50 ℃, can make the polypropylene-starch of preforming Mixed material.

[0051] The 2-5 layers of the mixed material are processed into dumbbell-shaped splines through an extruder, and the strength thereof is measured according to GB9341-2000, and t...

Embodiment 3

[0054] Raw material ratio (parts by weight):

[0055] 20 parts polypropylene

[0056] Starch 40 parts

[0057] 3.5 parts of glycerin

[0058] 1.5 parts of silane coupling agent

[0059] Glyceryl stearate 0.15 parts

[0060] Mix starch, glycerin, and silane coupling agent (vinyltrimethylsilane) at 75-85°C for about 10 minutes, grind them and put them into the supply box connected to the spray head 2; polypropylene and glyceryl stearate After mixing, it is heated to about 230-250°C and enters the supply box connected to sprinkler 1.

[0061] The setting and operation of spraying system are identical with embodiment 1, make the ejection speed of starch: the ejection speed of polypropylene=2:1, the temperature of cooling roll is about 60 ℃, can make the polypropylene-starch of preforming Mixed material.

[0062] The 2-5 layers of the mixed material are processed into dumbbell-shaped splines through an extruder, and the strength thereof is measured according to GB9341-2000, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com