Manufacturing procedure control method and system

A control method and technology of a control system, which are applied in the field of manufacturing process control, can solve the problem of no obvious improvement in process control, and achieve the effects of reducing waiting time and improving process efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical features of the present invention easy to understand, different embodiments and examples are proposed in the following disclosure, supplemented by drawings and specific text descriptions, to illustrate the present invention, but not to limit the present invention. If there are any modifications or changes related to the present invention in the described embodiments or examples, which can be naturally deduced by those skilled in the art, the present invention can be modified or changed accordingly to meet different requirements.

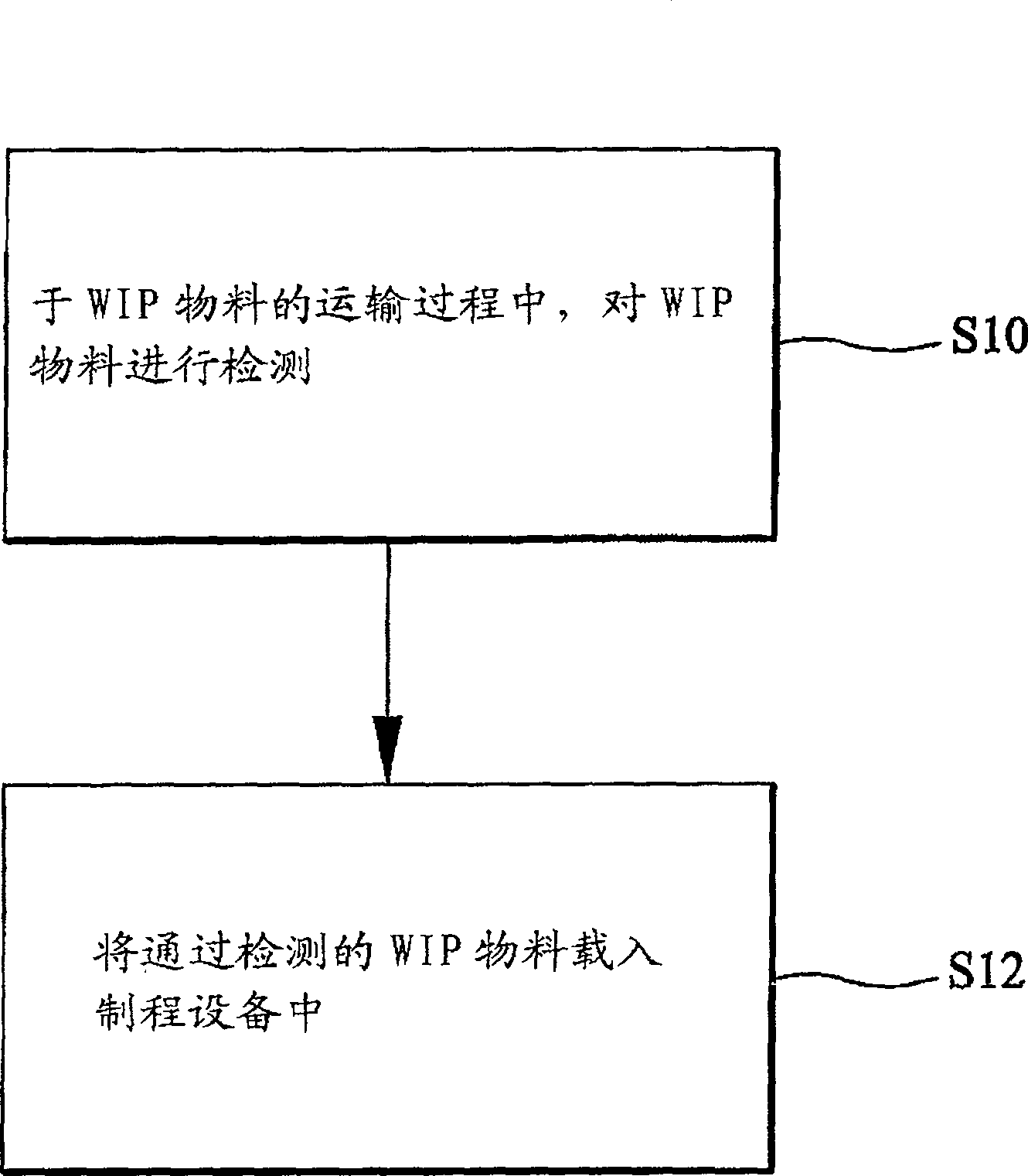

[0021] Please refer to figure 1 , figure 1 It is an execution flowchart showing an embodiment of the process control method disclosed in the present invention. As shown in the figure, firstly, the WIP material is detected during the transportation process of the WIP material, as shown in step S10. For example, if the method proposed by the present invention is applied to a semiconductor product manufacturing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com