Distributed automatic lubricating system

An automatic lubrication, distributed technology, applied in the direction of engine lubrication, lubricating parts, engine components, etc., can solve the problems of difficult control of the amount of fuel, laborious, unable to monitor the lubrication state of the oil replenishment point in real time, etc., to achieve the best practicability and Economical, broad market application prospects, and the effect of significant technological advancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

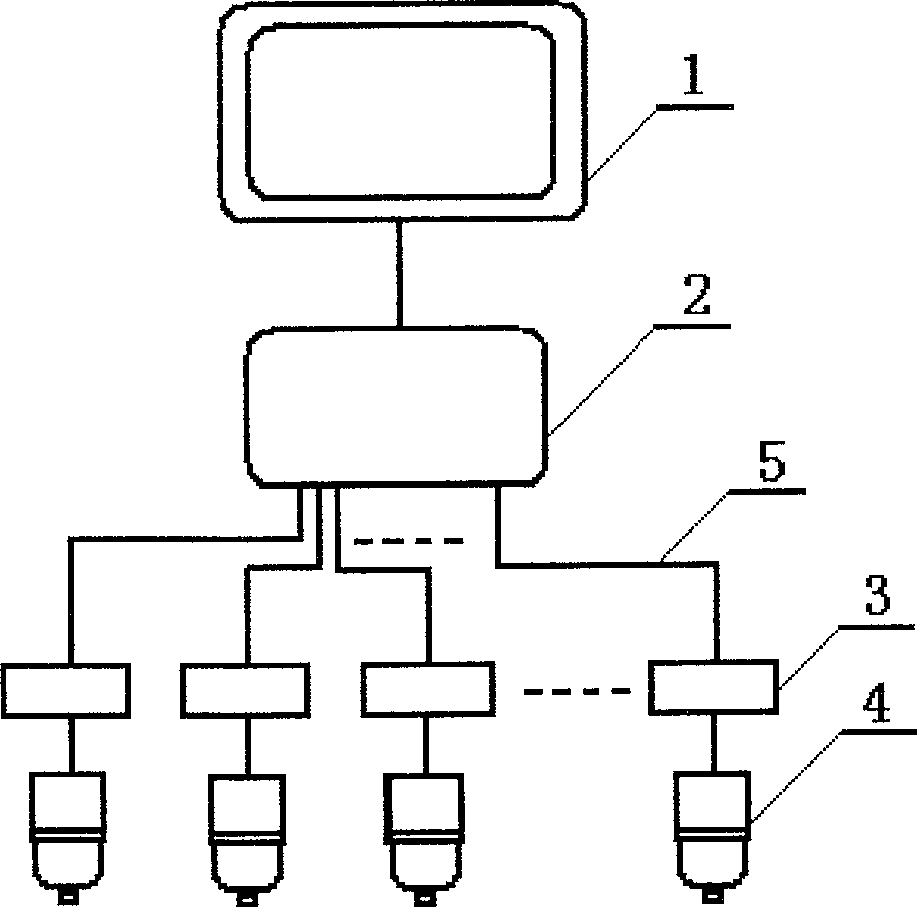

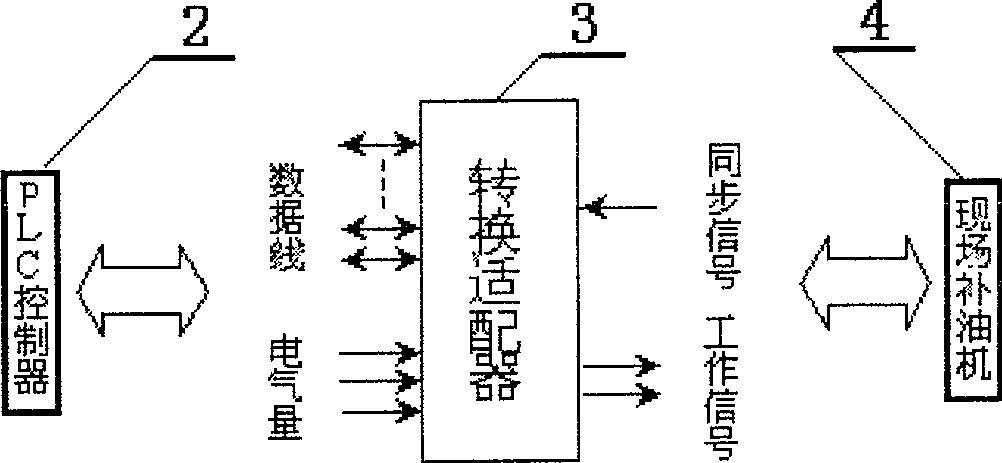

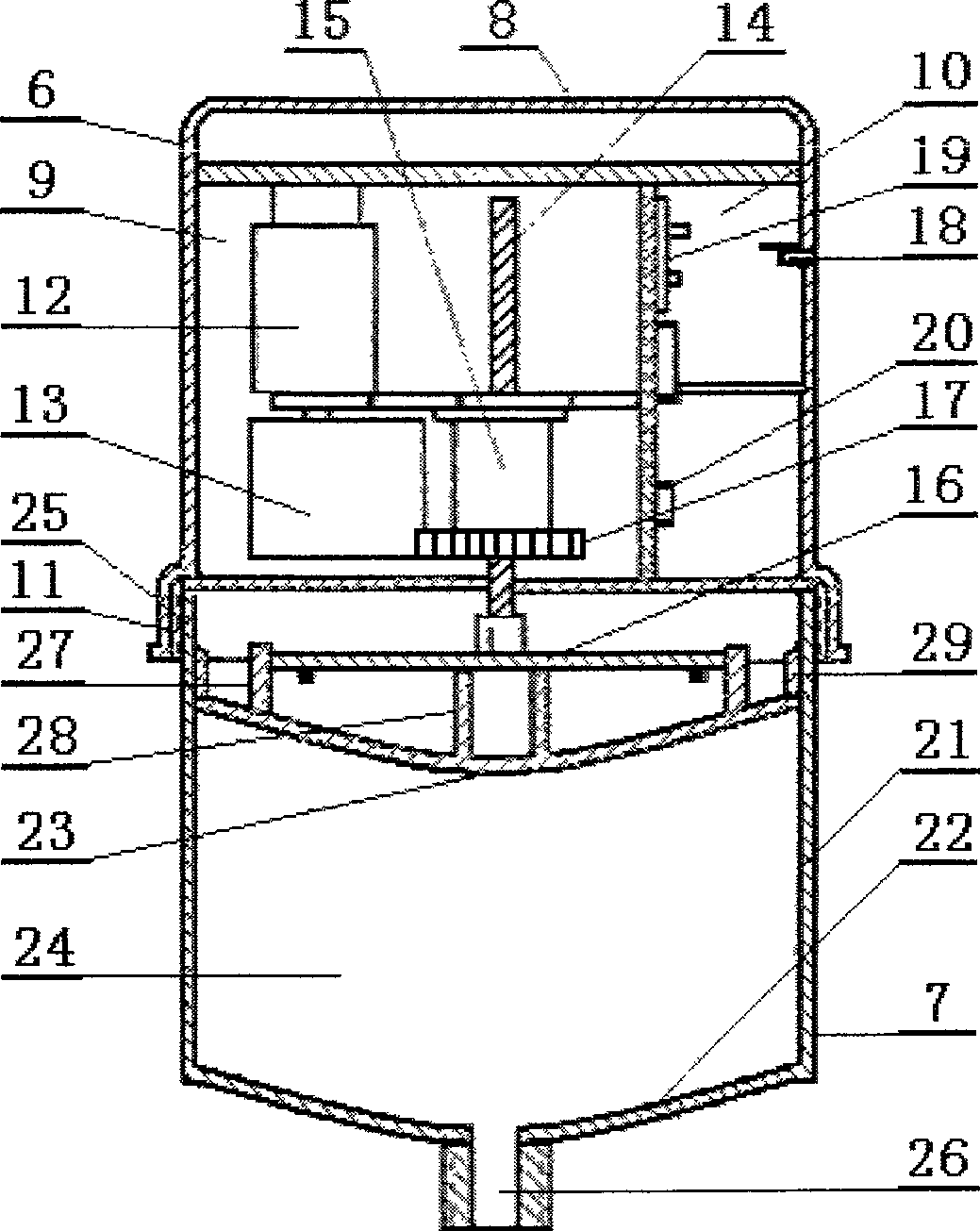

[0048] exist figure 1 and figure 2 Among them, the distributed automatic lubrication system of the present invention is mainly composed of the upper HMI human-machine interface 1, the controller 2, the conversion adapter 3, the on-site oil replenishment machine 4 and the communication system 5. Among them: the upper HMI human-machine interface 1 is mainly composed of industrial computer or integrated workstation, system software, and application program; the controller 2 is set between the upper HMI human-machine interface 1 and the conversion adapter 3, and the main body is composed of a programmable controller PLC , and the upper HMI human-machine interface 1 are connected by industrial Ethernet or field bus, and the conversion adapter 3 is directly connected by field bus point-to-point; the conversion adapter 3 is set between the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com