Device for removing farci flour dough sticker

A technology of sharp objects and dough, applied in the direction of dough forming and cutting equipment, etc., can solve the problems of cumbersome and complex structure, low production efficiency, and inability to enter multiple doughs separately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

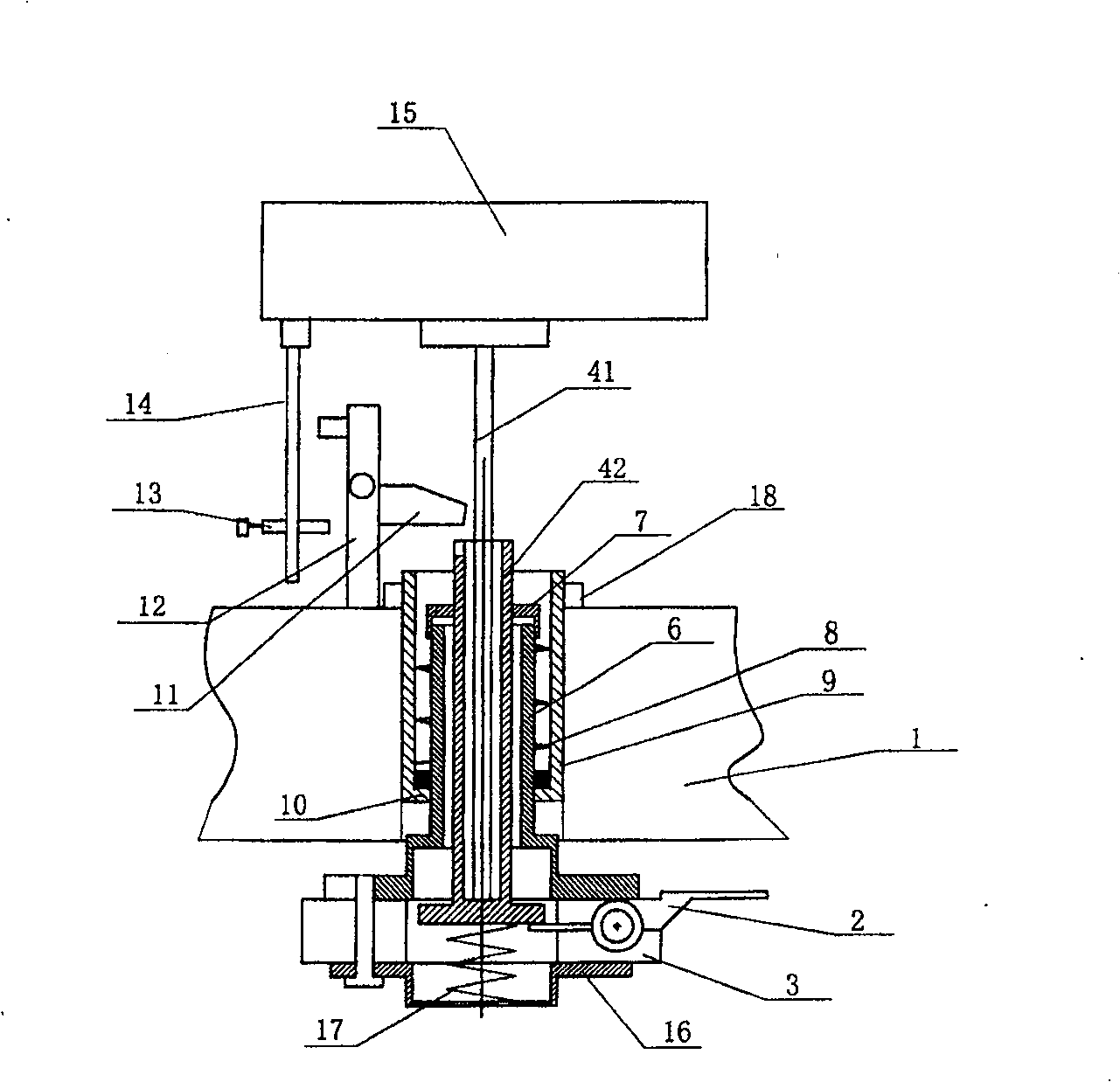

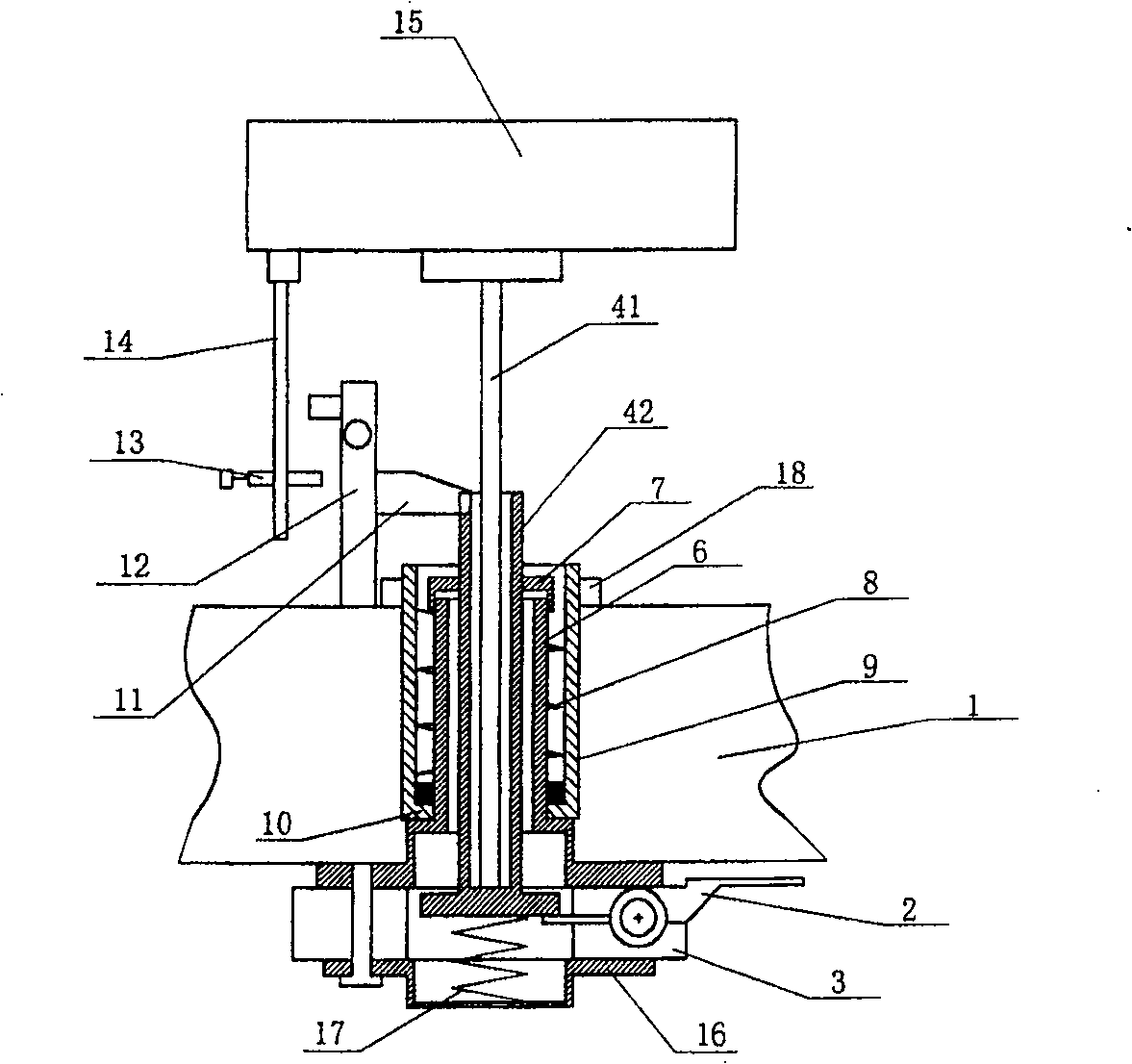

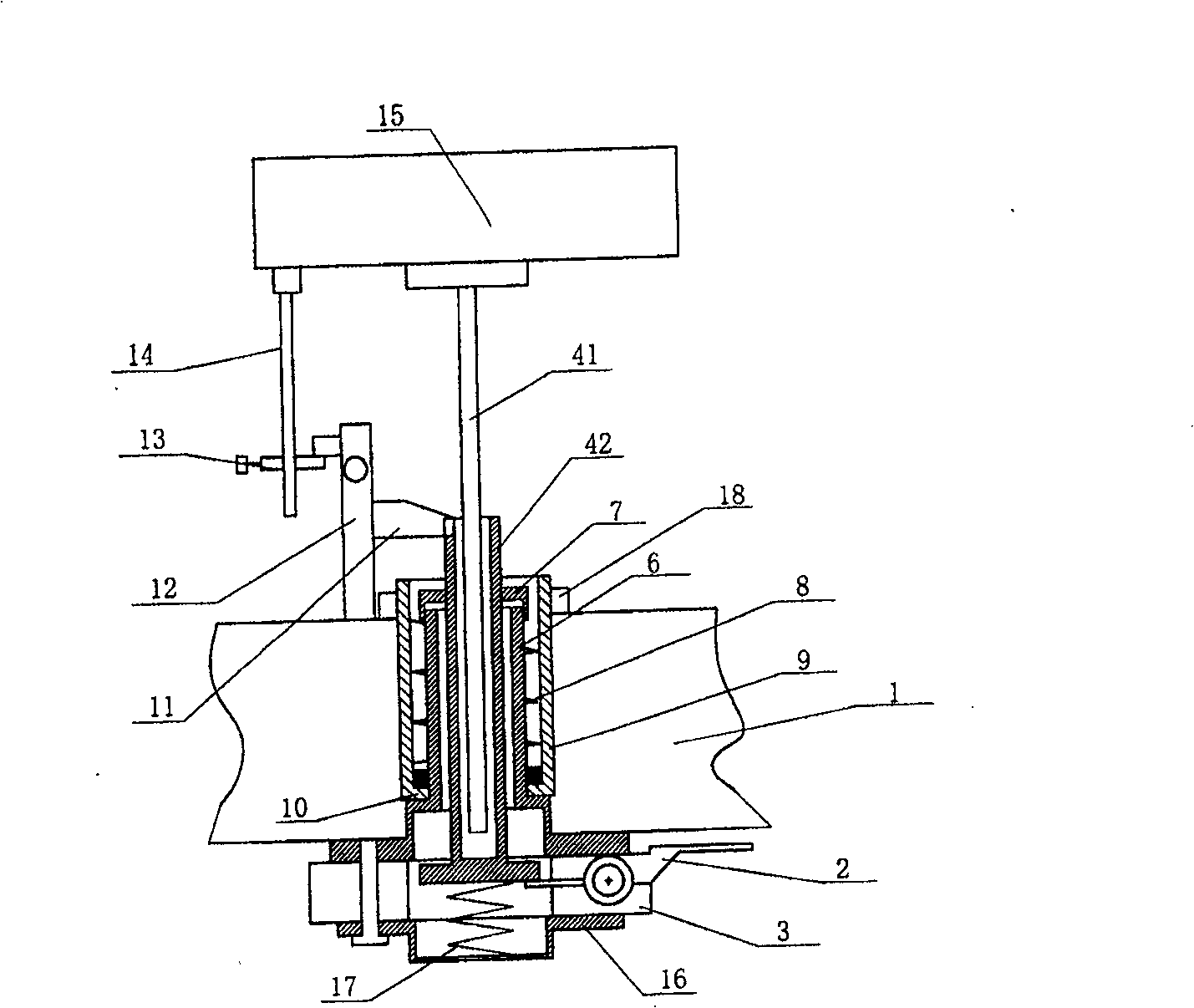

[0030] Figure 1a , 1b, 1c, 1d is a schematic diagram of the action process of the device for eliminating the cutting dough spikes of the present invention. in Figure 1a It is the state diagram when the cutter disc is in the upper stop position, and the cutter disc is separated from the pallet frame at this time; Figure 1b It is the state diagram of the cutter disc in the middle position. At this time, the cutter disc is attached to the pallet frame, and the pressing rod is locked on the movable sleeve rod, but the ejector rod and the movable sleeve rod have not been separated; Figure 1c It is the state diagram when the cutting disc reaches the bottom stop but the pressing rod has not been triggered, and the ejector rod and the movable sleeve rod have been separated at this time; Figure 1d It is the state diagram after the cutter disc has reached the bottom stop and the pressure bar has been triggered. At this time, the movable sleeve lever has been reset, and the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com