Armrest for a vehicle

A technology for handrails and vehicles, which is applied in the direction of handrails, special positions of vehicles, vehicle components, etc., and can solve the problems of no longer guaranteeing the intact function of the handrails and wear of the stop bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

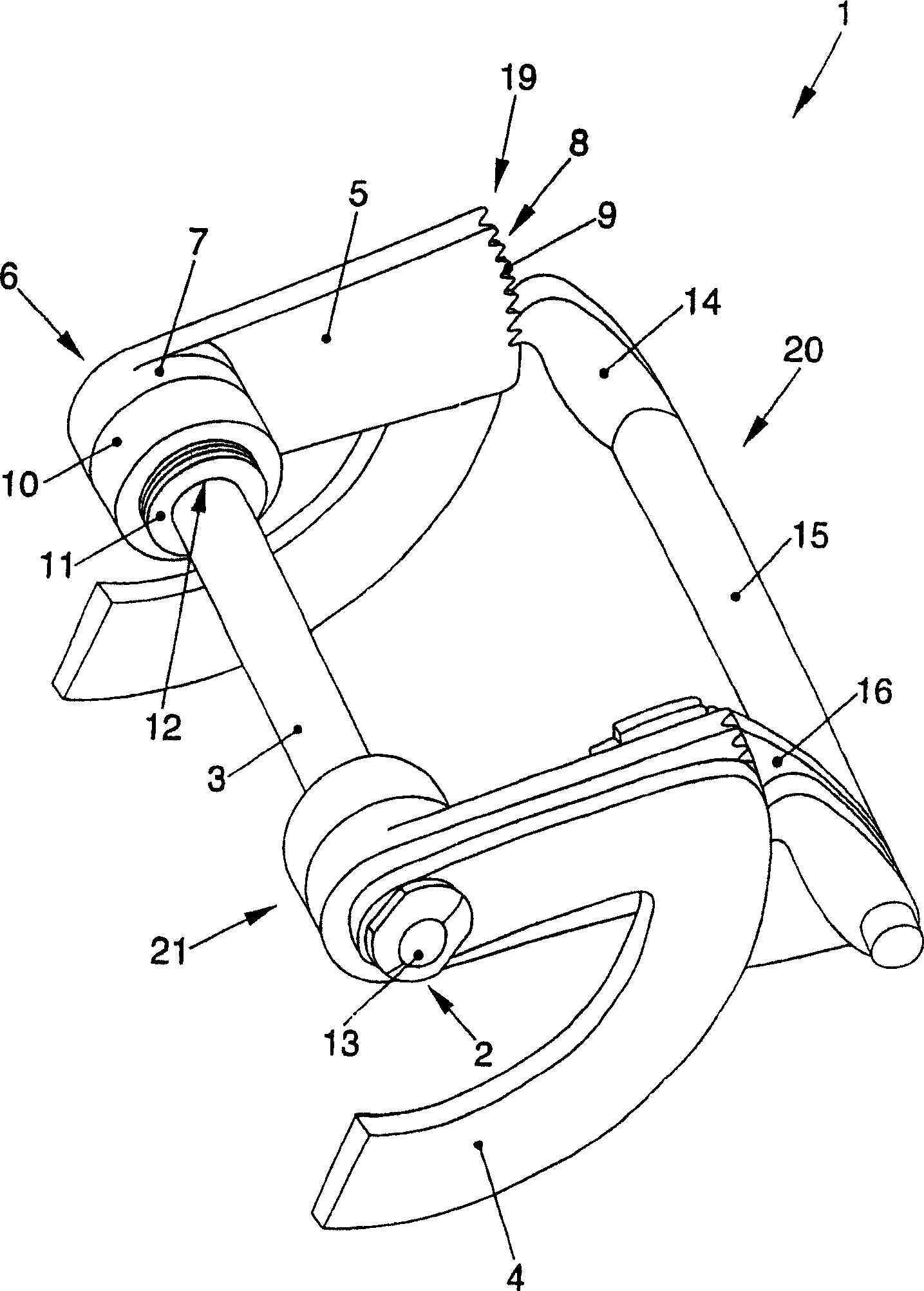

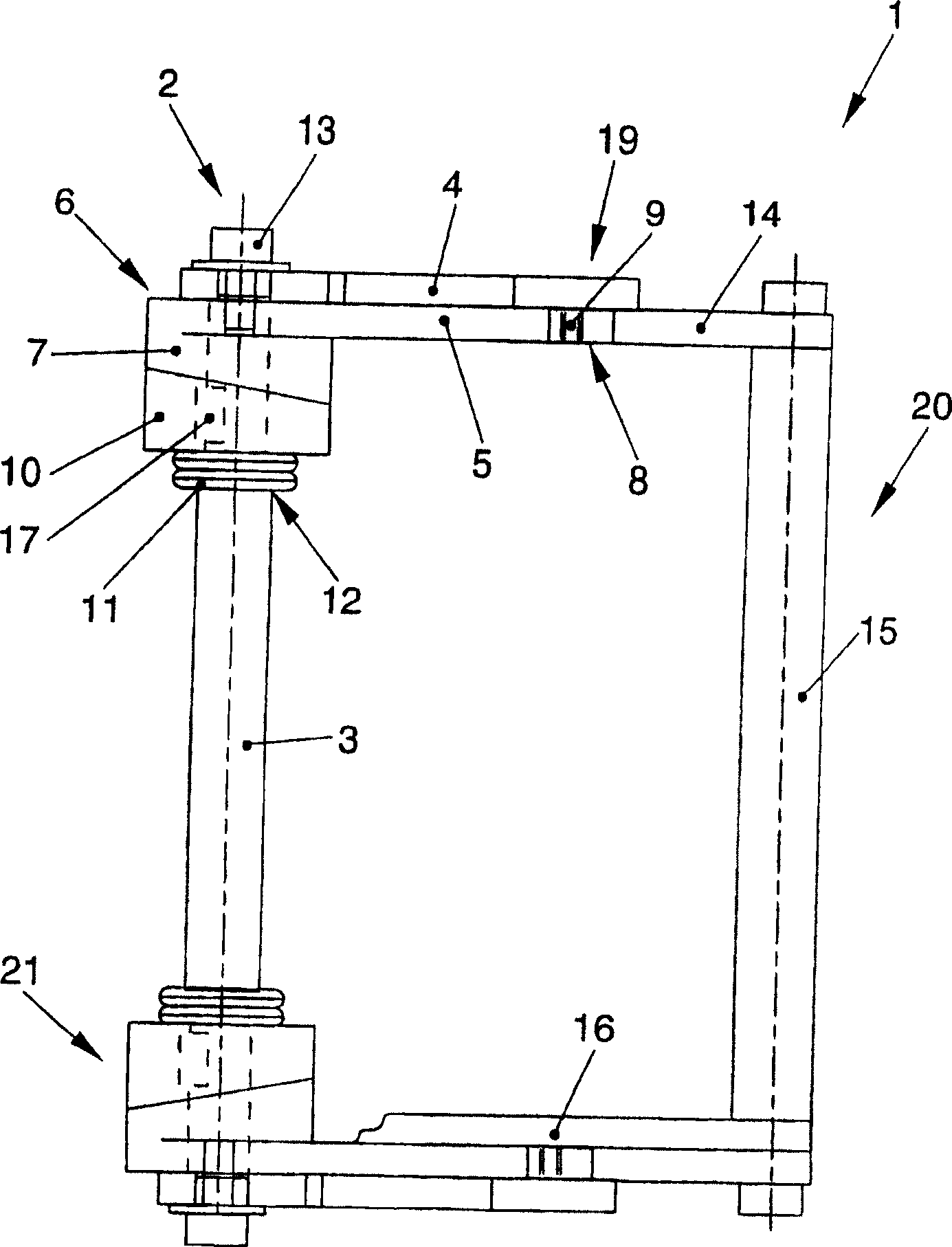

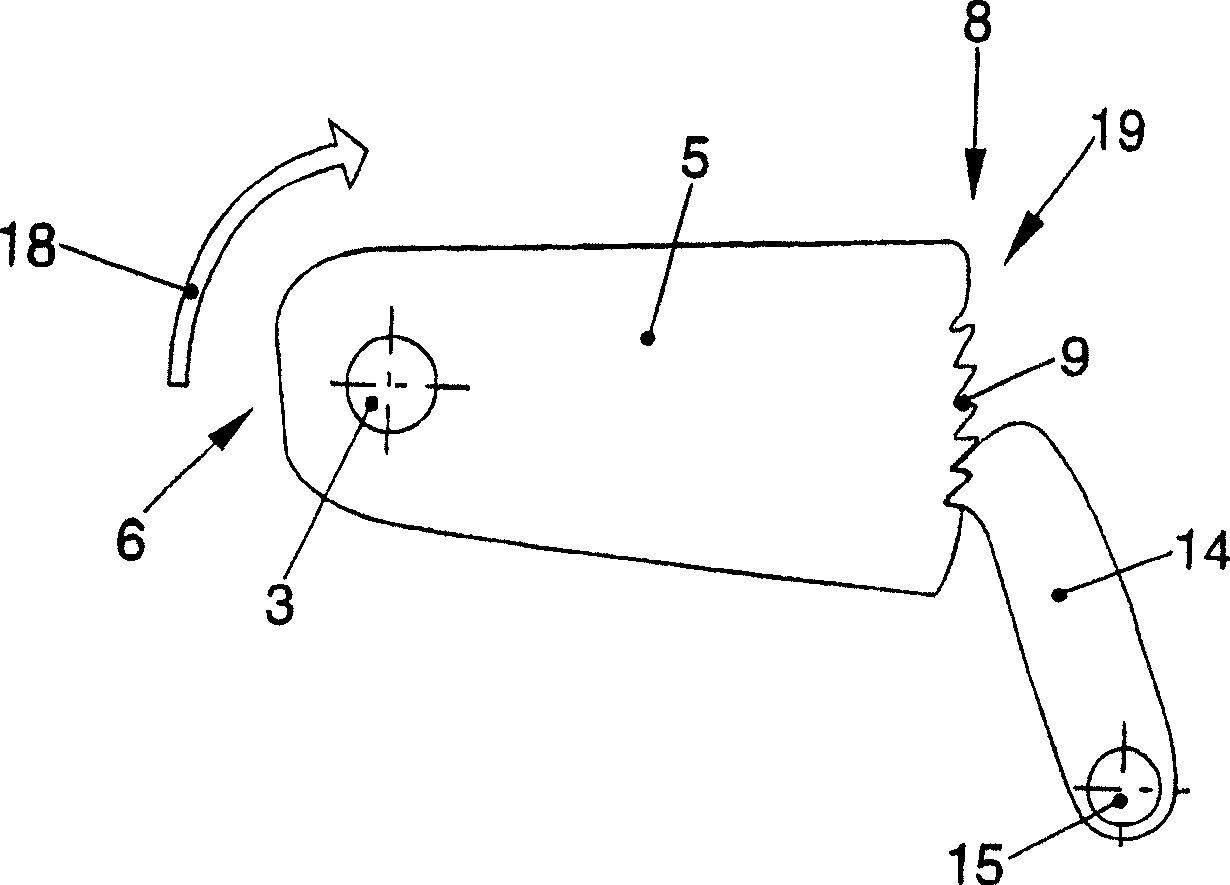

[0029] figure 1 The main body diagram of an armrest 1 is briefly shown. For the sake of clarity, the actual support for the arm and armrest 1 is not shown together. An armrest bracket 4 is provided at both ends 2 of a rotating shaft 3 in a non-rotatable manner. The armrest bracket 4 is screwed on the end of the rotary shaft 2 with a screw 13 respectively, which simultaneously realizes the prevention of rotation. The support body of the armrest 1 not shown can be connected with the armrest bracket 4. A stop / overload bracket 5 is provided directly adjacent to the armrest bracket 4, which is rotatably supported on the rotating shaft with a clamping end 6. A clamping element 7 is provided on the clamping end 6 of the stop / overload bracket 5. A stop end 8 is provided on the stop / overload bracket 5 in an arcuate and radial direction with respect to the rotating shaft 3. Many positioning protrusions 9 are provided on the stop end 8.

[0030] Corresponding to the clamping element 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com