Diving electric pump with decelerator

A submersible electric pump and technology with a reducer, which is applied to components with teeth, pumps, pump devices, etc., can solve the problems of large motor volume, high cost, affecting the effective water section of the wellbore, and achieve compact structure and low cost. , the effect of significant use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

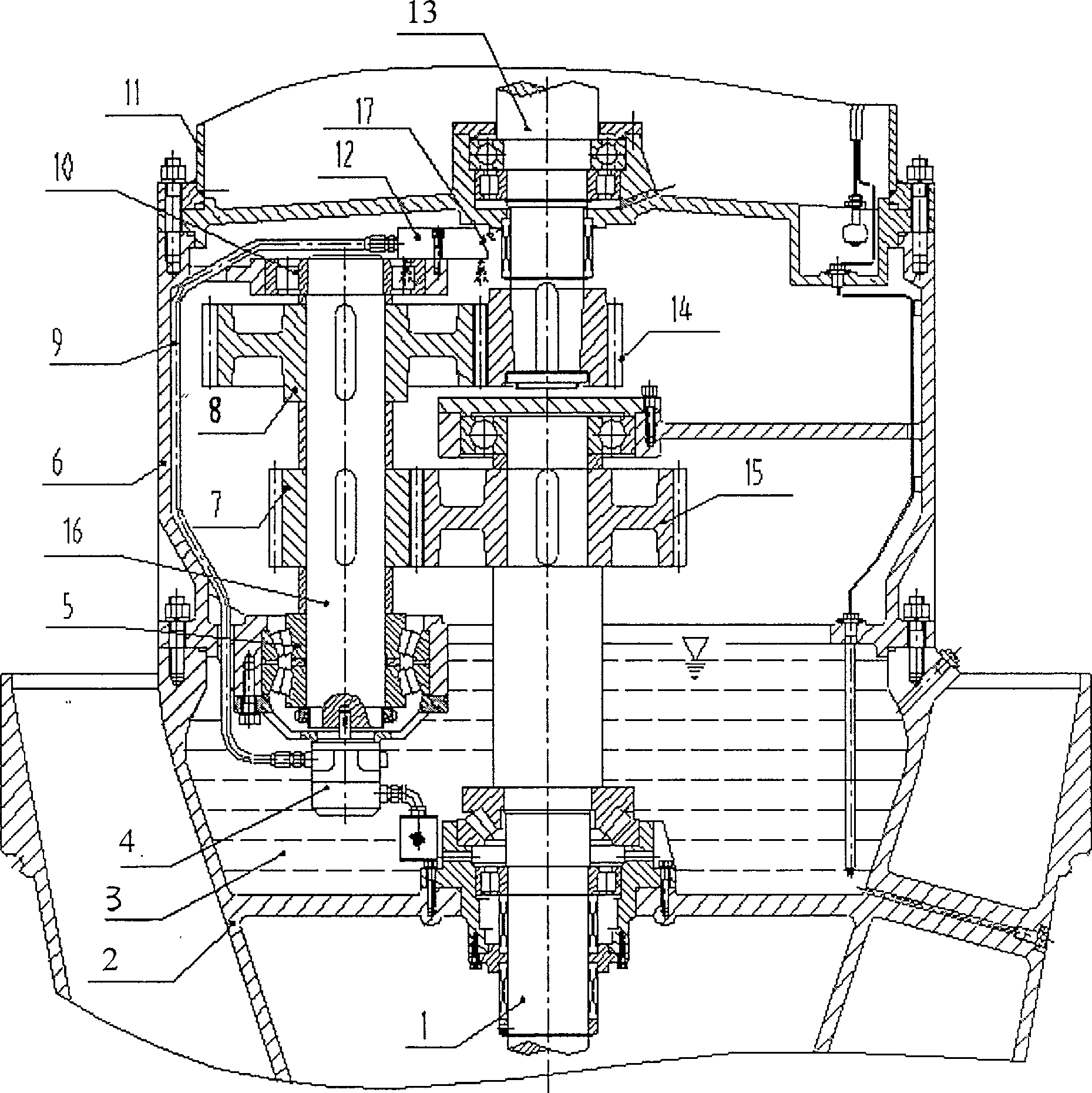

[0012] like figure 1 As shown, a submersible electric pump with a reducer of the present invention is composed of a motor 11, a pump body, a water pump guide vane body 2 and a pump shaft 1, and the water pump guide vane body 2 is arranged inside the pump body, The pump shaft 1 is arranged on the partition plate inside the water pump guide vane body 2 through a bearing, and an oil chamber cavity 3 is arranged on the upper part of the internal partition plate of the water pump guide vane body, wherein, in the water pump guide vane body 2 is also provided with a reduction gearbox 6, the motor 11 is arranged on the top of the gearbox 6, the shaft 13 of the motor 11 is arranged inside the gearbox 6 through a bearing, and the reduction gear Gear box 6 is provided with a speed reduction mechanism, the speed reduction mechanism is composed of the first pinion 14, the second pinion 7, the first bull gear 8, the second bull gear 15 and the transmission shaft 16, the transmission shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com