Method and system for detecting medicament of liquid in bottles

A detection method and a technology for bottled liquids, which are applied in the direction of optical detection of defects/defects, sorting, etc., can solve the problems of slow detection speed, low detection quality, and small application range, and achieve fast detection speed, high detection quality, and reasonable settings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

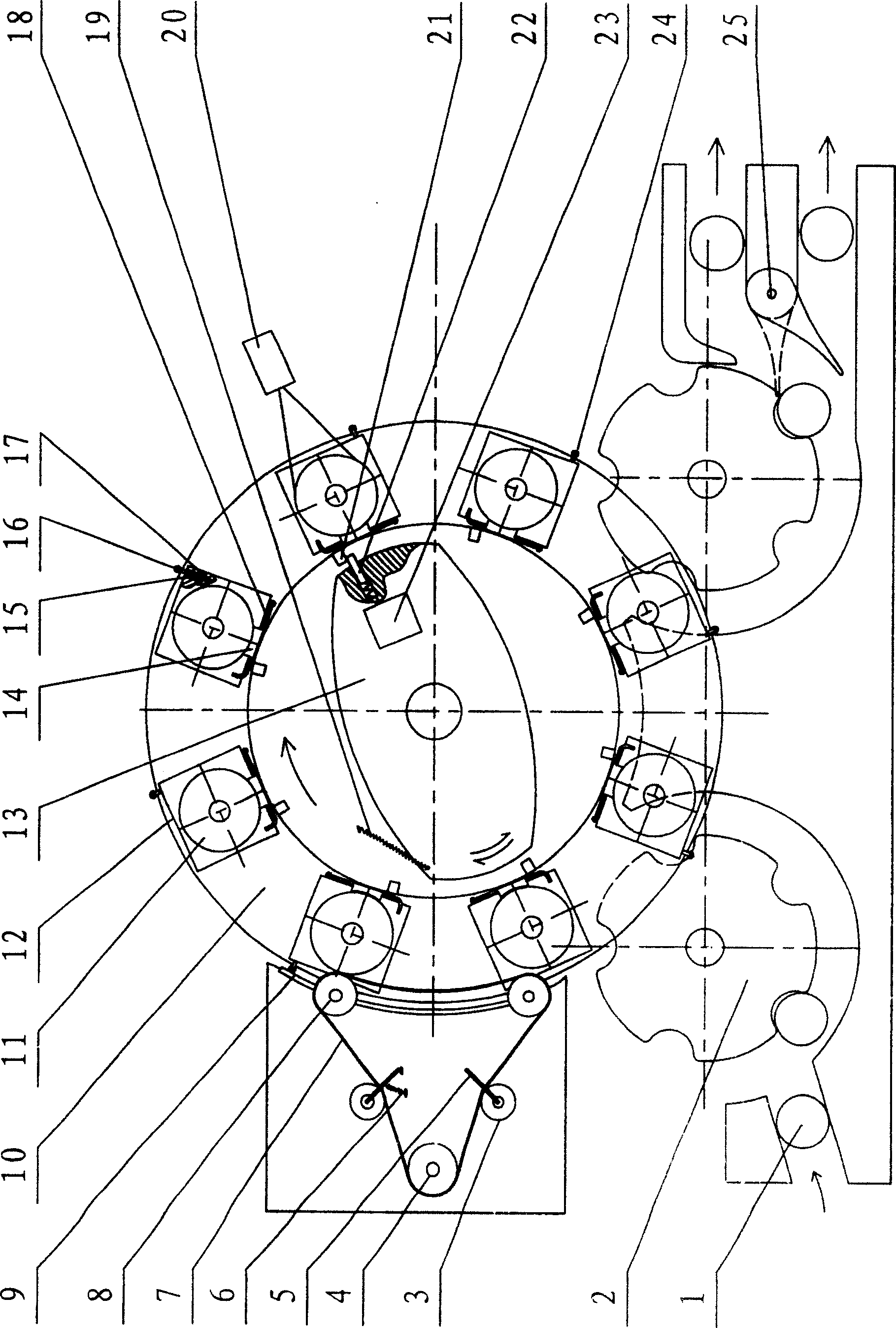

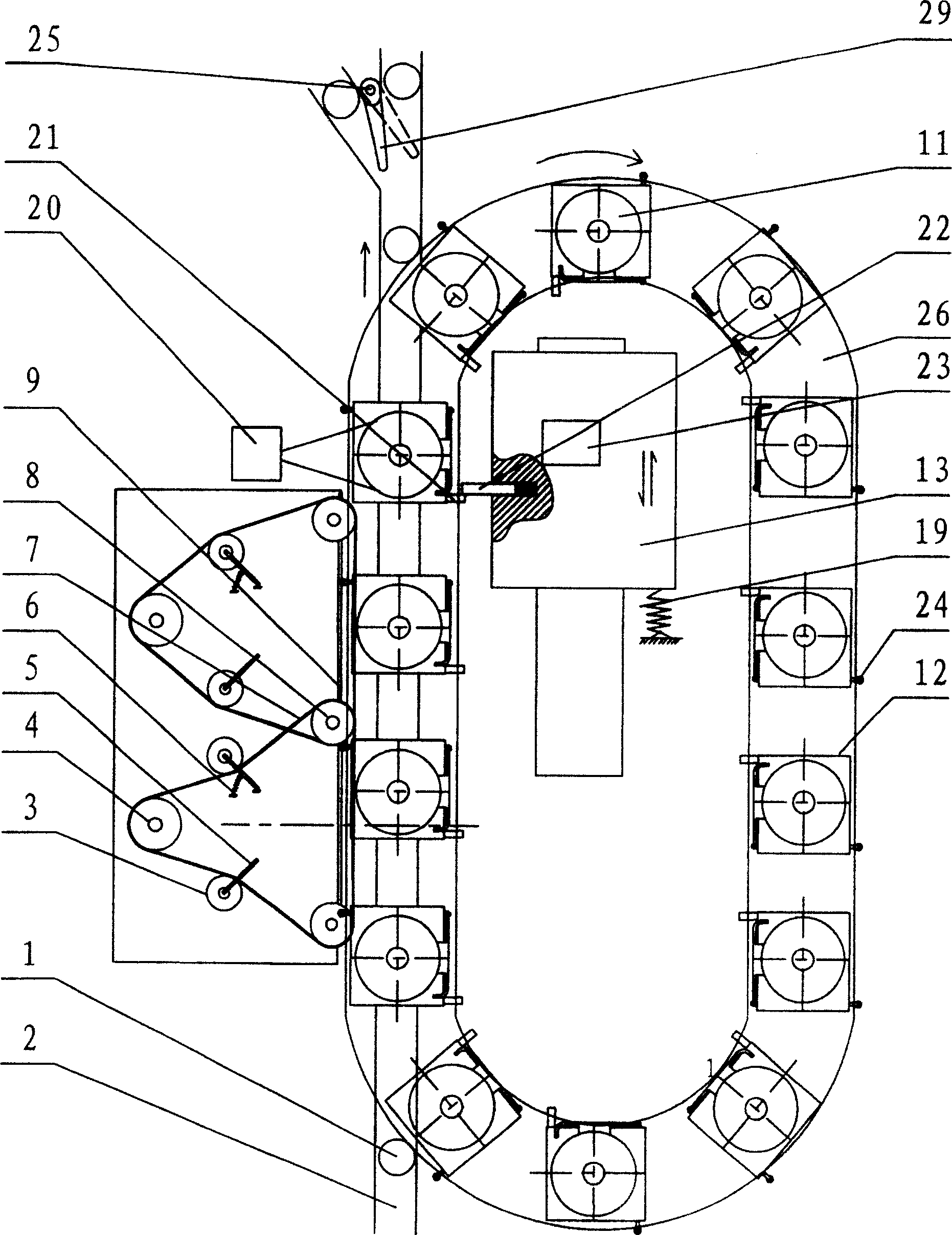

[0040] A specific detection method for bottled liquid medicine of the present invention comprises: the clamping device clamps a measured bottle from the bottle feeding device and rotates around the axis of the rotary table at a reasonable speed at a constant speed until the measured bottle passes through the belt friction drive device 1. The detection device reaches the bottle output device; the belt friction drive device drives the bottle body to rotate at a uniform acceleration around its own axis for 0.8 seconds until the speed reaches the set 300 rpm; the drive bottle body maintains the set speed and continues to rotate at a constant speed for 0.8 seconds ; The braking device quickly brakes the rotating bottle within 0.02 seconds and brakes until the bottle reaches the bottle outlet device; emits low-temperature visible light beams from the bottom of the bottle to the bottle, around the axis of the rotary table and the detection An ordinary camera that rotates the bottle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com