Toner

A technology of toner and toner particles, applied in the field of toner, can solve the problem of not mentioning addition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

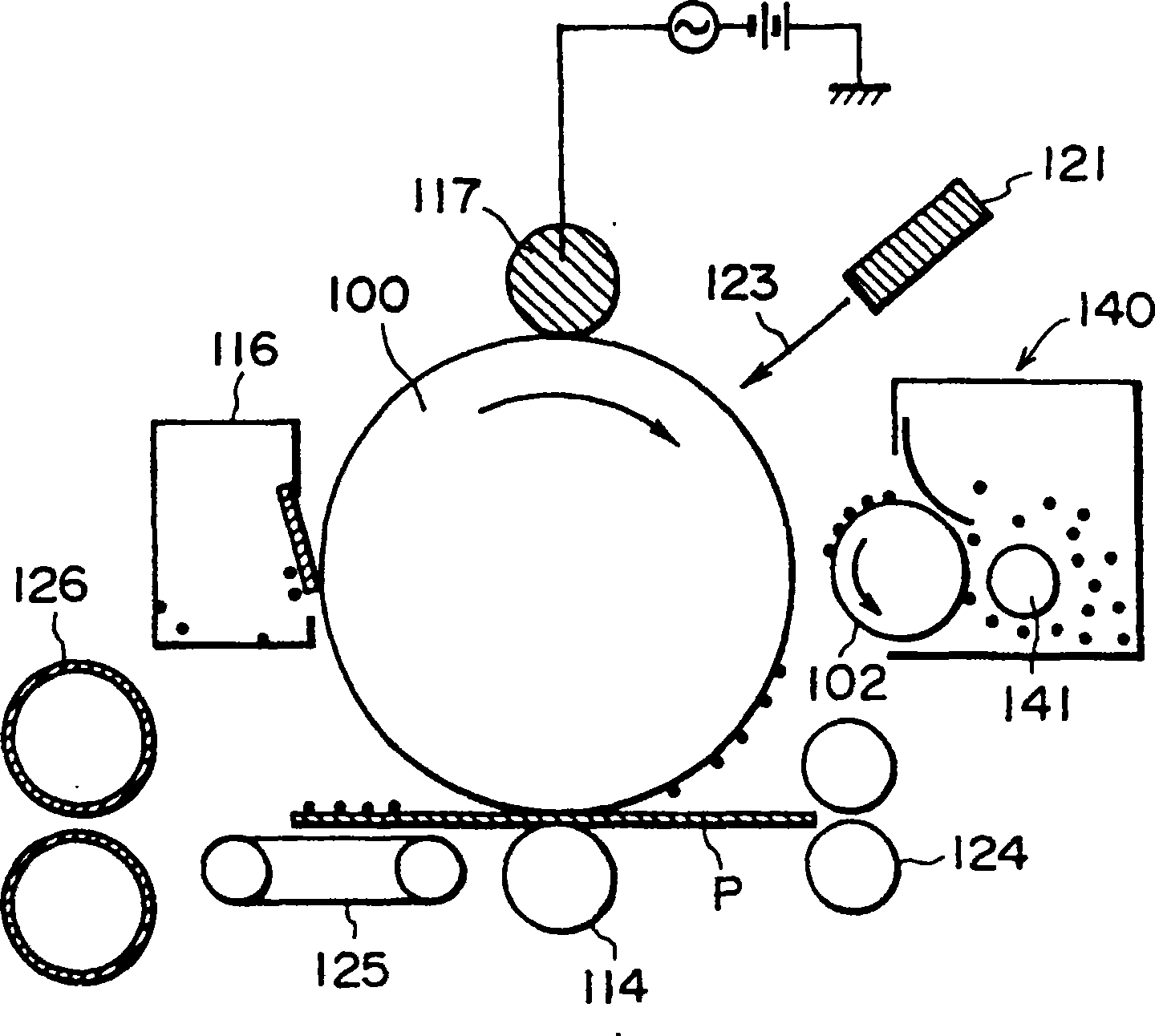

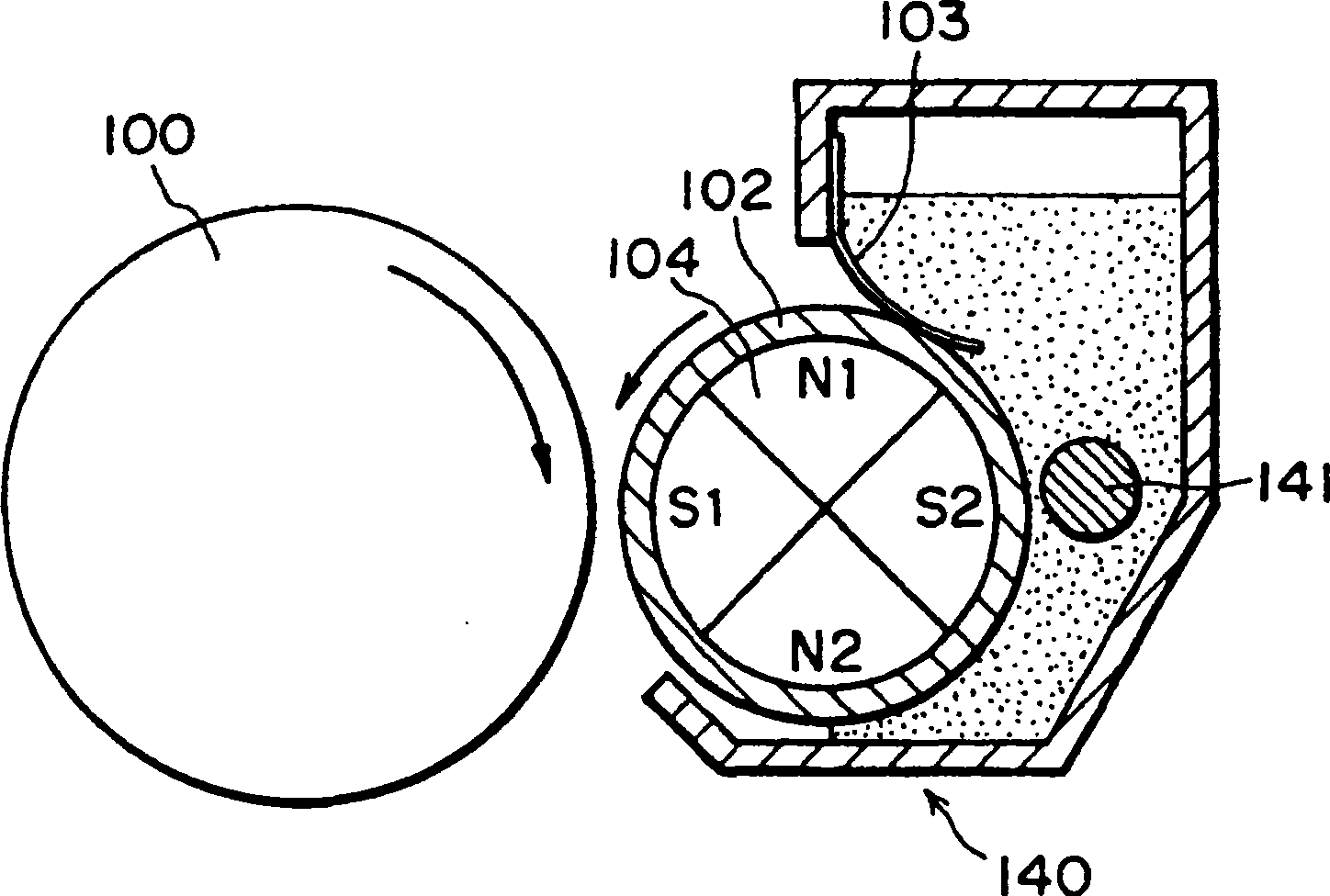

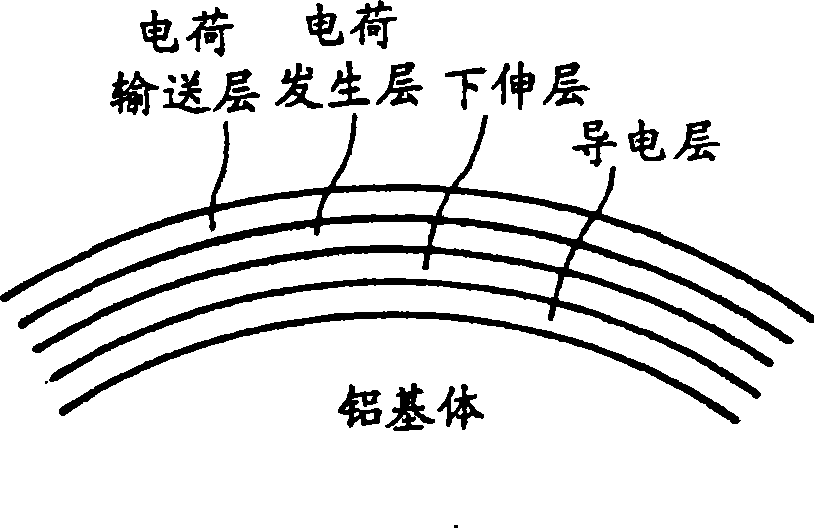

Method used

Image

Examples

Embodiment

[0362] The following describes the present invention in more detail through manufacturing examples and embodiments, but this description does not constitute a limitation to the present invention. In addition, the parts in the following compounding ratios are all parts by mass.

[0363] (A-1) Manufacturing of fine particles

[0364] ① Manufacturing of fine particles A-1

[0365] According to the way that the molar ratio of tungsten (W) to tin (Sn) (W / Sn) is 0.05, tin chloride (SnCl 4 ·5H 2 O) and tungstic acid (H 2 WO 4 ) In aqueous solution. According to the mass ratio of tin element: titanium oxide of 2.2:1, while stirring the above mixed aqueous solution at a temperature of 90°C, the mixed aqueous solution was dropped to disperse 200 parts by mass of the titanium oxide forming the matrix particles in Then, hydrochloric acid was added to the suspension solution formed in 2000 parts by mass of water, and the generated coprecipitate was filtered and dried.

[0366] In an electric f...

Embodiment A-1

[0383] (1) Production of toner A-1

[0384] To the toner particles A-1 (100 parts by mass), add hydrophobic silica fine powder (1.2 parts by mass) treated with fine particles A-1 (1.5 parts by mass) and dimethyl silicone oil, and add it to In the Henschel mixer, toner A-1 was prepared. The ratio of fine particles present on the toner surface was 5.0 per toner particle, and the particle diameter ratio of the fine particles to the average diameter of the toner was 0.09.

[0385] (2) Manufacturing of carrier A-1

[0386] As a developing carrier for a two-component developer, the following developing carrier A-1 was produced, in which 0.8 parts by mass of acrylic resin was coated with respect to 100 parts by mass of 45 μm ferrite particles.

[0387] (3) Preparation of two-component developer A-1

[0388] With respect to the developer carrier A-1: 100 parts by mass, 7 parts by mass of the toner A-1 were mixed to obtain a two-component system developer A-1.

[0389] Using the obtained...

Embodiment A-2

[0411] In the production of the toner A-1, the toner particles A-2 and the fine particles A-2 were used for the change, and the addition amount of the fine particles was changed to 1.0 part by mass, except for this, the same method was used. , Toner A-2 was prepared. The ratio of fine particles present on the surface of the toner was 2.2 per toner particle, and the particle size ratio of the fine particles to the average diameter of the toner was 0.07.

[0412] A two-component developer A-2 was prepared in the same manner as in Example A-1 except that the toner A-2 was used, and the evaluation was performed in the same manner. In Example A-2, a high-quality image was obtained. The evaluation results related to the above items are given in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com