Lens centering machine

A core-adjusting machine and lens technology, applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of larger installation space and inability to carry workpieces, and reduce the installation area of the machine , save the trouble of moving pallets, and increase the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

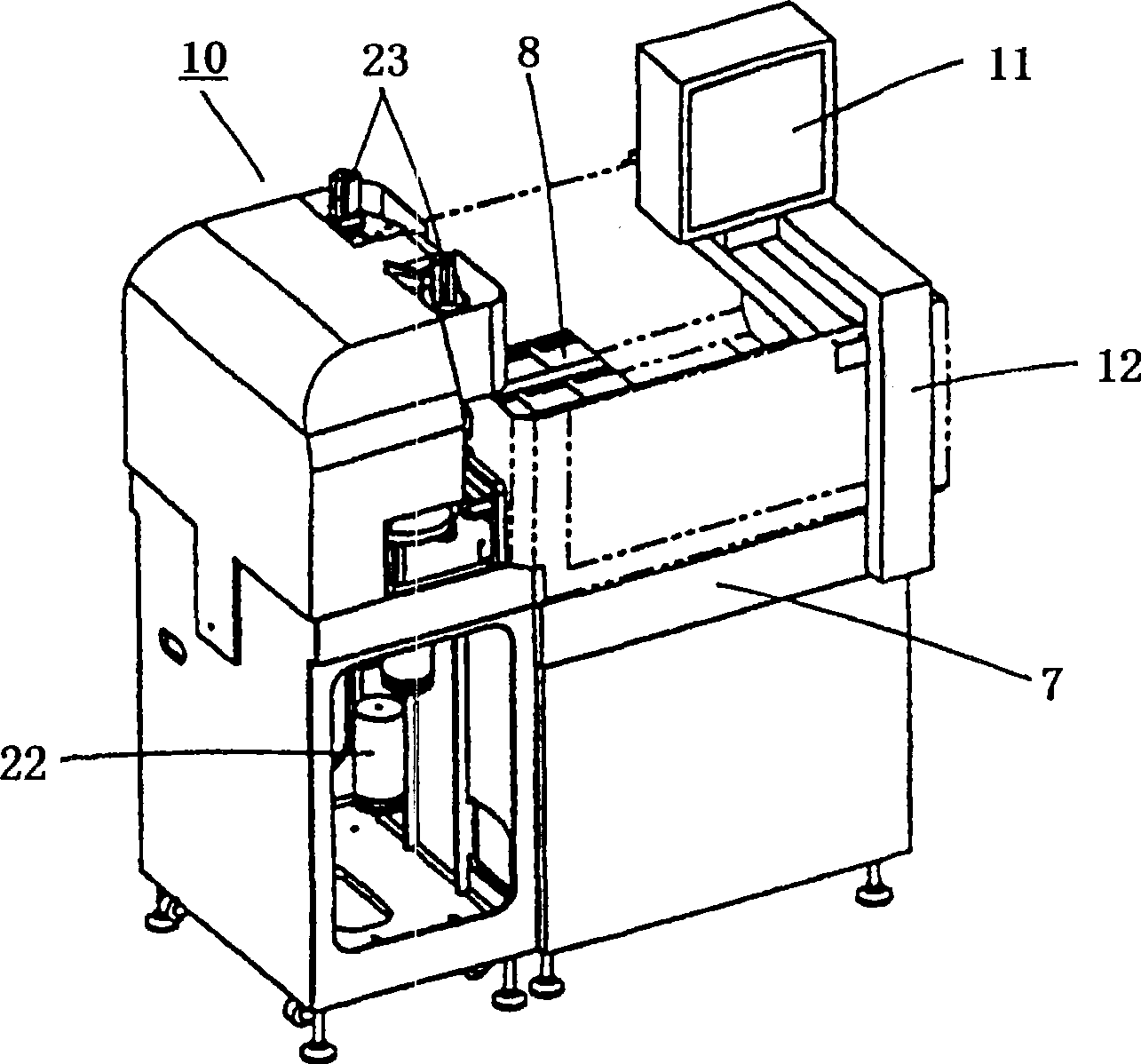

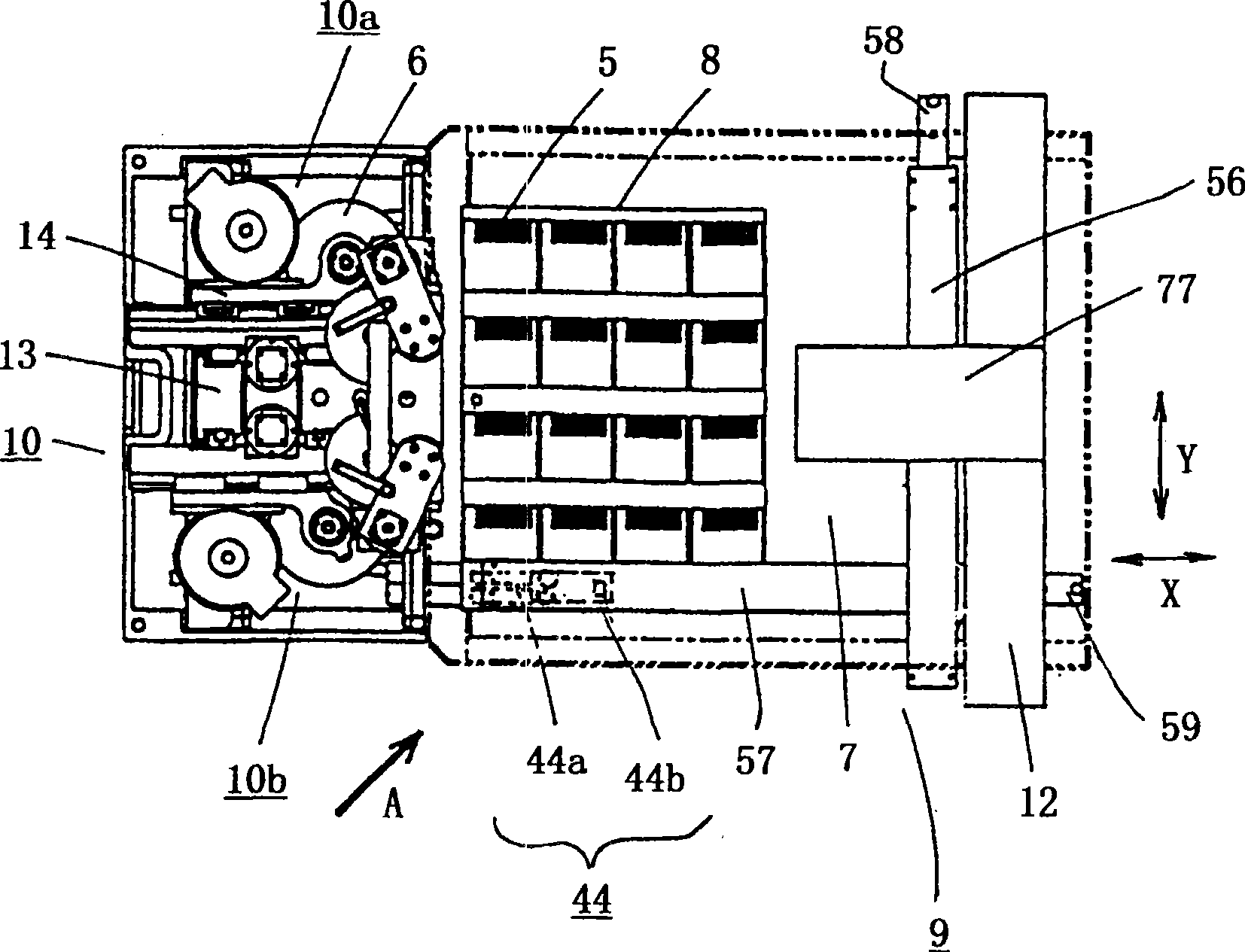

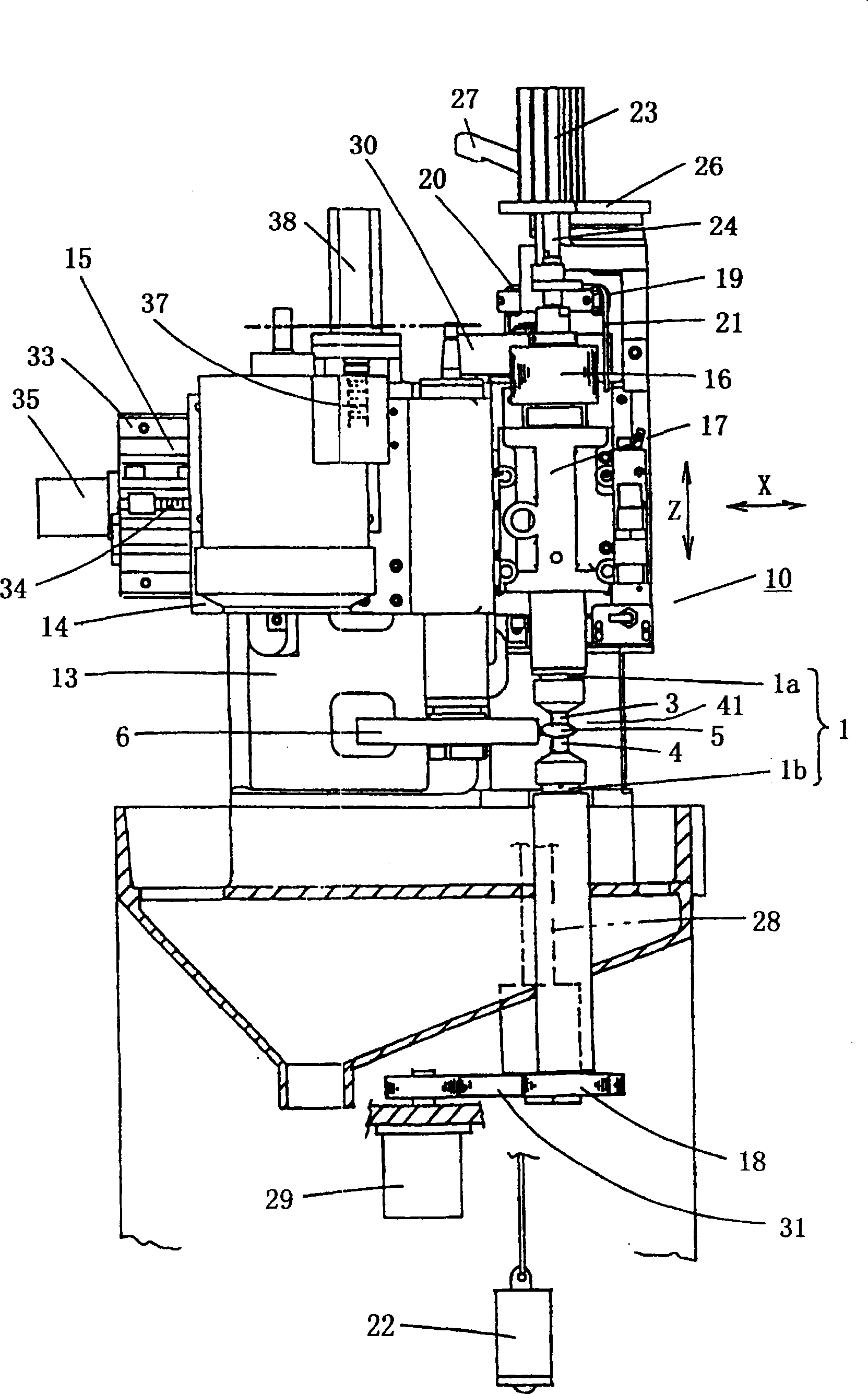

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 is from the front left side ( figure 2 Arrow A direction) to see the overall perspective view of the machine of the embodiment device, figure 2 It is a schematic top view of the whole machine, image 3 is the side view of the processing unit, Figure 4 It is the top view of two groups of processing units.

[0045] exist figure 1 , figure 2 Among them, 7 is a work table, 8 is a pallet mounted on the work table 7, and the lenses 5 before and after processing are held on receiving tables provided in matrix on each pallet. 57 is the arm of the loader, which is used by the workpiece table 7 figure 2 The guide beam 56 in the up and down direction (Y direction) guides and runs directly above the workpiece table 7 . On the loader arm 57 there is an edge figure 2 The conveying head 44 that travels in the left and right direction (X direction). On the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com