Method for preventing etching or corrosion of metallic titanium in screen layer

A technology of metal titanium and barrier layer, which is applied in the field of semiconductor integrated circuit technology, can solve problems such as reduction of contact surface, influence on yield rate, reliability problems, etc., and achieve the effect of preventing etching and improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

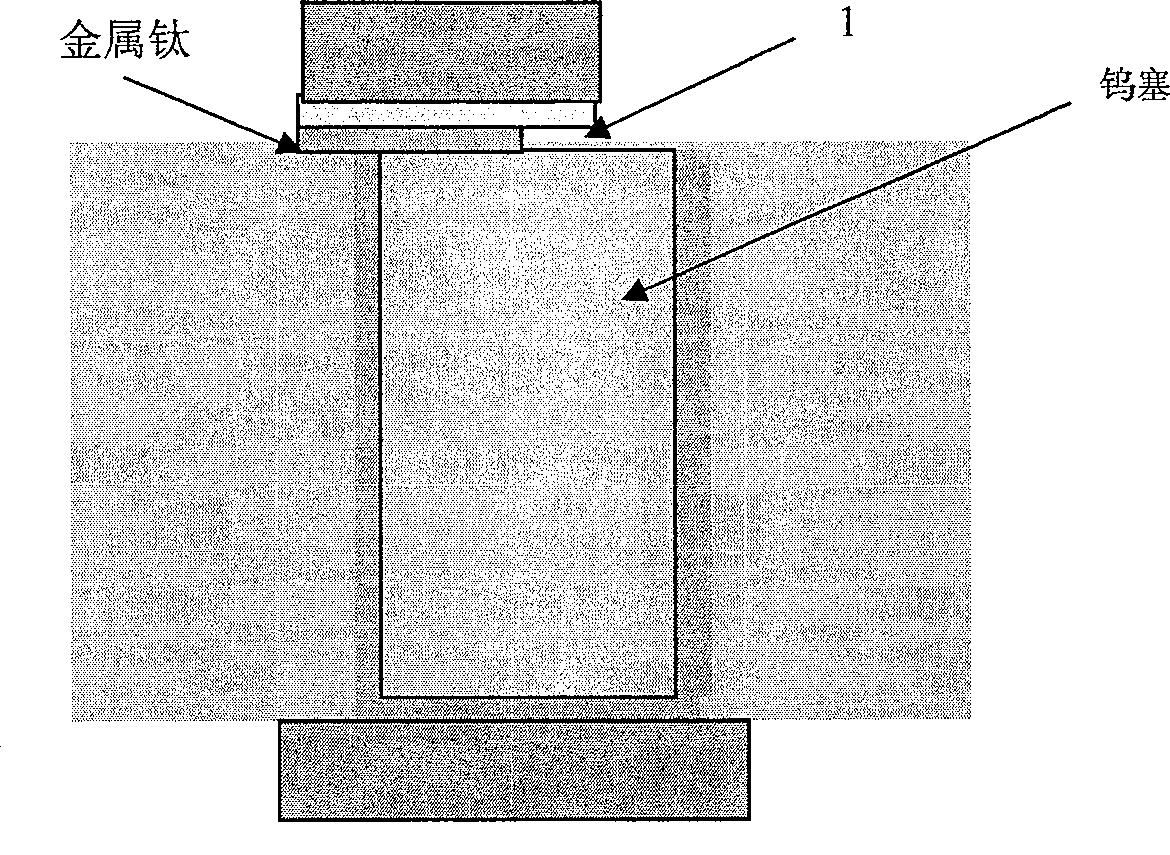

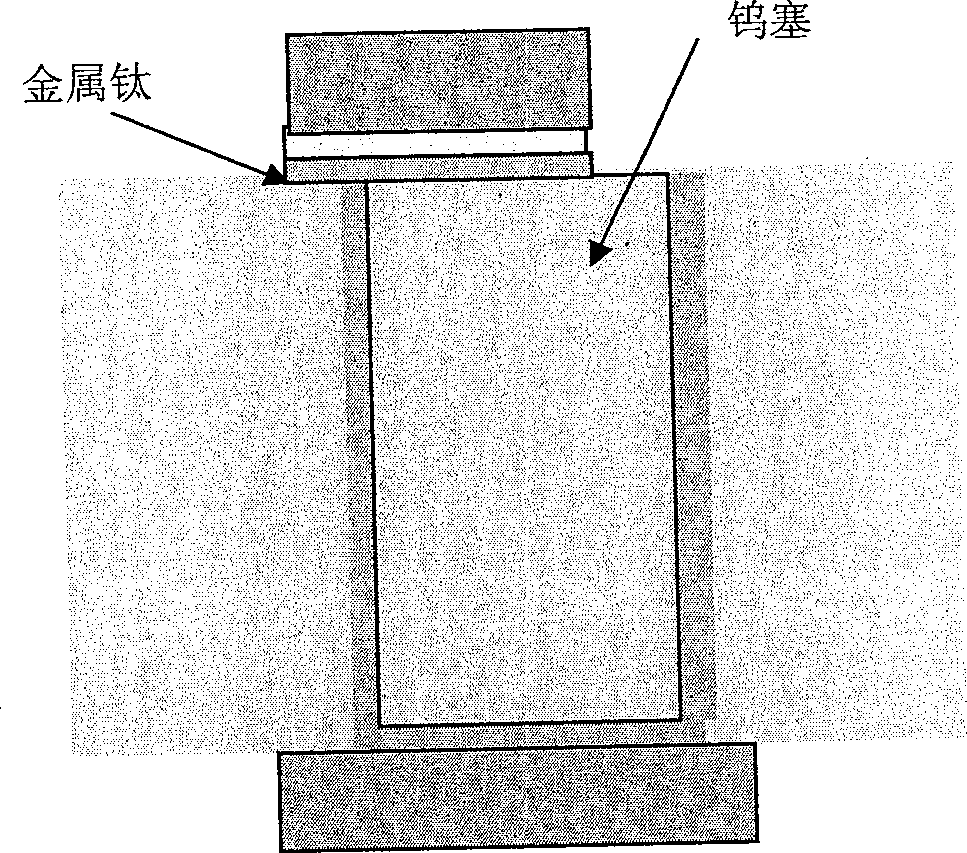

[0023] The study found that the plasma radio frequency (RF) treatment process before sputtering of titanium in the barrier layer has a significant impact on the surface roughness of the tungsten plug, thus affecting the adhesion between titanium and tungsten plug. If the method of optimizing the RF treatment process can effectively improve the adhesion performance of titanium and tungsten plugs, and then achieve the purpose of preventing etching. Just based on the above design, the method of the present invention proposes to optimize the RF processing technology.

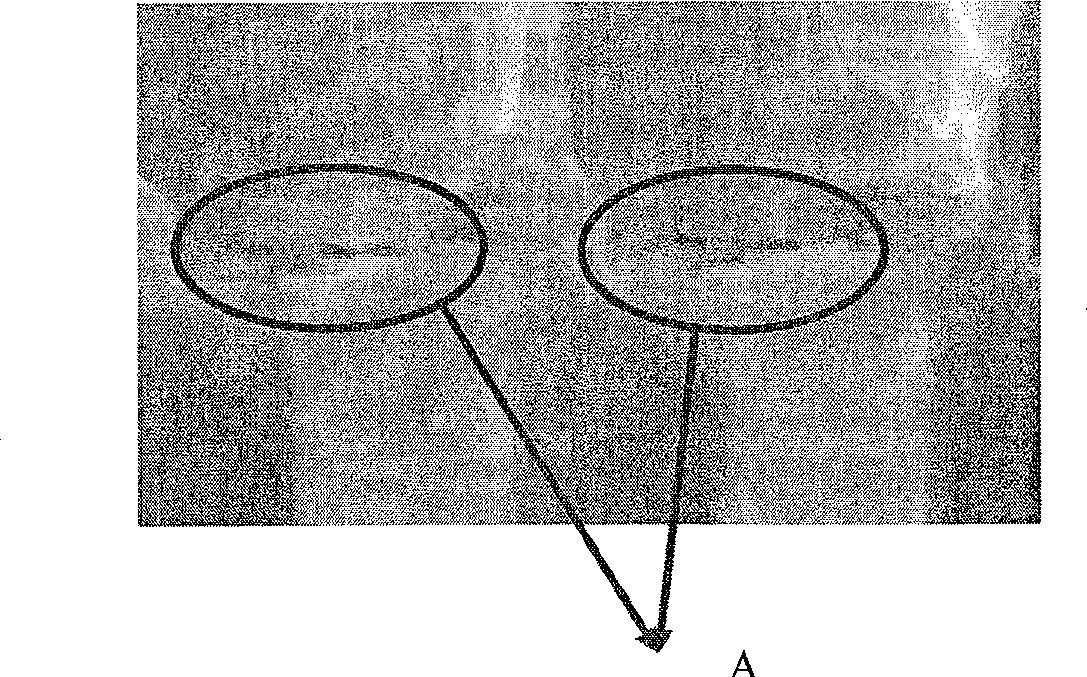

[0024] First, the RF treatment process before TI sputtering can be removed. At this time, it is available from the attached image 3 It can be seen that the titanium metal is intact at this time.

[0025] Secondly, in the RF treatment before TI's sputtering, the process conditions in the RF treatment can be controlled in the following range: SiO 2 The loss is 0-60 angstroms, the temperature is 260°C-320°C, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com