A kind of preparation method of cubic silicon carbide coating

A cubic silicon carbide and coating technology, which is applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve the problems of shortening the service life of graphite materials, achieve broad application fields, corrosion-resistant structures, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

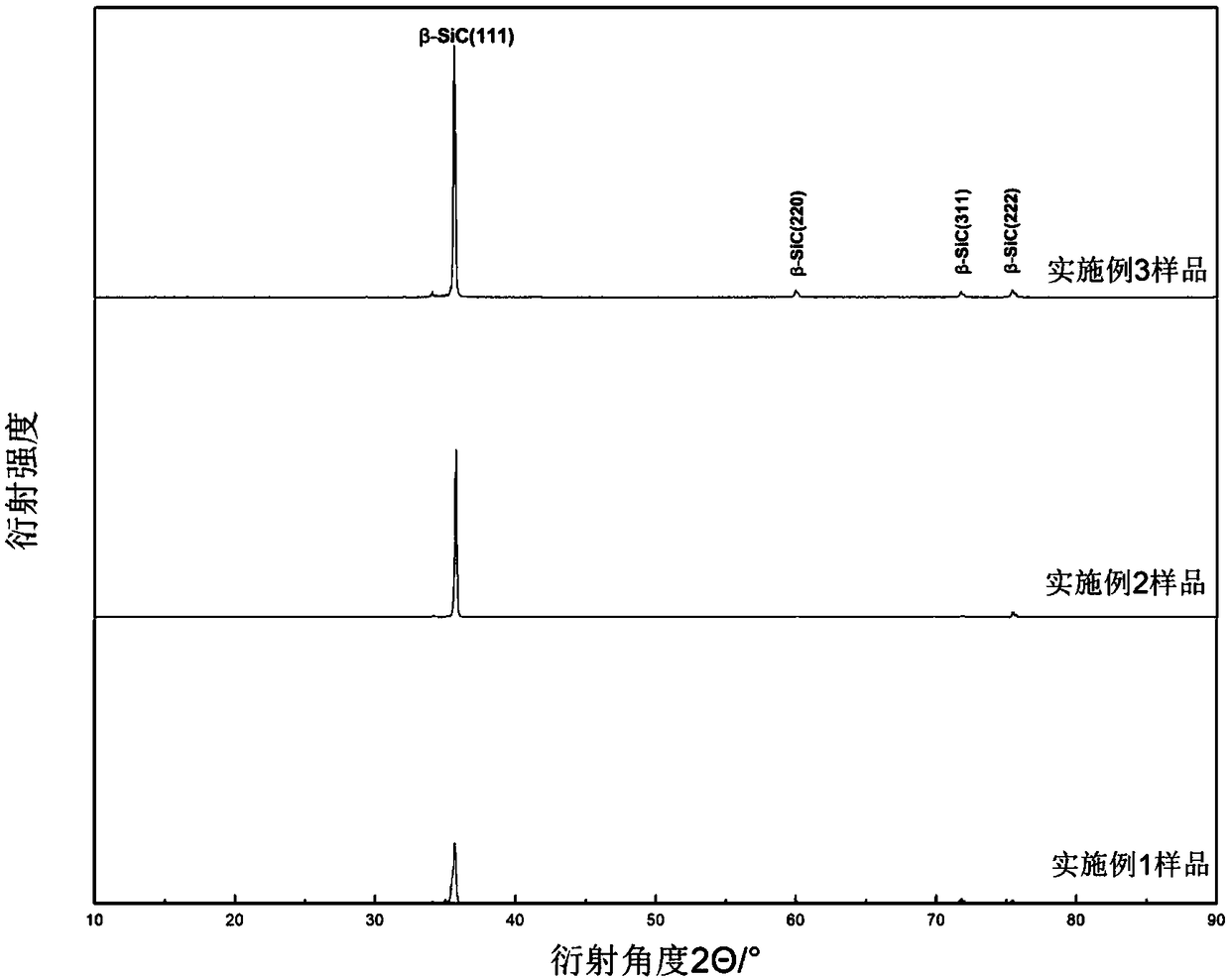

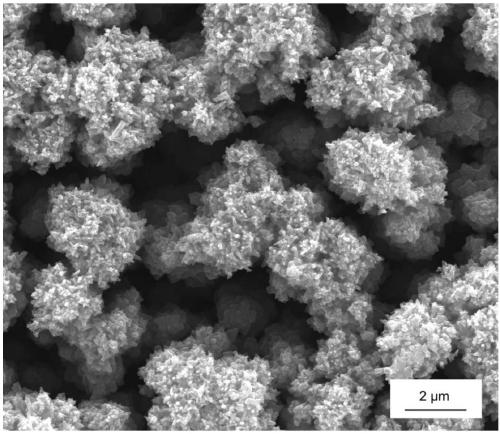

Embodiment 1

[0029] A method for preparing a cubic silicon carbide coating, comprising the steps of

[0030] 1) Put the graphite substrate on the substrate base in the reaction chamber of the cold-wall laser chemical vapor deposition device, and vacuumize to reduce the pressure in the device to 1-10Pa;

[0031] 2) Pass in diluent gas H 2 , H 2 The flow rate is 2500sccm;

[0032] 3) Turn on the laser to irradiate the surface of the graphite substrate, the laser wavelength is 1050nm; adjust the laser power to raise the temperature of the graphite substrate to 1320°C and keep it warm;

[0033] 4) Open the carrier gas containing HMDS, the flow rate of HMDS is 3 sccm;

[0034] 5) Adjust the pressure in the reaction chamber to 3000Pa, and keep it for 20 minutes for deposition reaction;

[0035] 6) Turn off the laser, the carrier gas containing HMDS and the diluent gas, evacuate to below 10Pa, and cool naturally to room temperature, that is, a cubic silicon carbide coating is deposited on the...

Embodiment 2

[0038] A method for preparing a cubic silicon carbide coating, comprising the steps of

[0039] 1) Put the graphite substrate on the substrate base in the reaction chamber of the cold-wall laser chemical vapor deposition device, and vacuumize to reduce the pressure in the device to 1-10Pa;

[0040] 2) Pass in diluent gas H 2 , H 2 The flow rate is 2000sccm;

[0041] 3) Turn on the laser to irradiate the surface of the graphite substrate, the laser wavelength is 1050nm; adjust the laser power to raise the temperature of the graphite substrate to 1250°C and keep it warm;

[0042] 4) Open the carrier gas containing HMDS, the flow rate of HMDS is 5 sccm;

[0043] 5) Adjust the pressure in the reaction chamber to 4500Pa, and keep it for 10 minutes for deposition reaction;

[0044] 6) Turn off the laser, the carrier gas containing HMDS and the diluent gas, evacuate to below 10Pa, and cool naturally to room temperature, that is, a cubic silicon carbide coating is deposited on the...

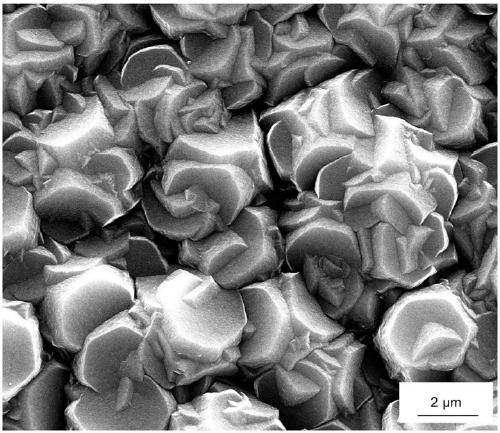

Embodiment 3

[0047] A method for preparing a cubic silicon carbide coating, comprising the steps of

[0048] 1) Put the graphite substrate on the substrate base in the reaction chamber of the cold-wall laser chemical vapor deposition device, and vacuumize to reduce the pressure in the device to 1-10Pa;

[0049] 2) Pass in diluent gas H 2 , H 2 The flow rate is 3000sccm;

[0050] 3) Turn on the laser to irradiate the surface of the graphite substrate, the laser wavelength is 1050nm; adjust the laser power to raise the temperature of the graphite substrate to 1450°C and keep it warm;

[0051] 4) Open the carrier gas containing HMDS, the flow rate of HMDS is 1 sccm;

[0052] 5) Adjust the pressure in the reaction chamber to 2500Pa, and keep it for 30 minutes for deposition reaction;

[0053] 6) Turn off the laser, the carrier gas containing HMDS and the diluent gas, evacuate to below 10Pa, and cool naturally to room temperature, that is, a cubic silicon carbide coating is deposited on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com