Semiconductor device and method of manufacturing the same

A semiconductor and electrode technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as inability to achieve conduction, and achieve the effect of preventing etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

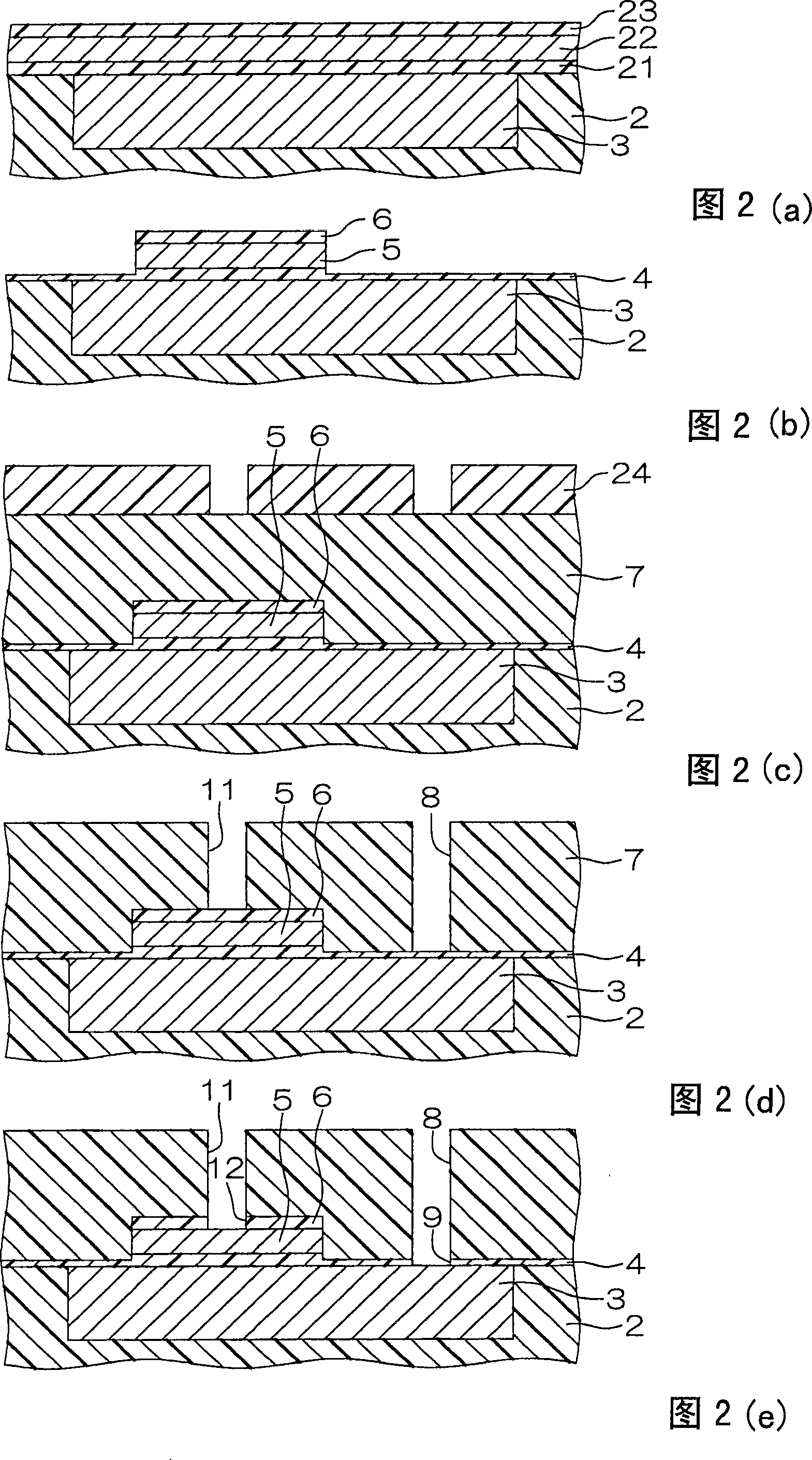

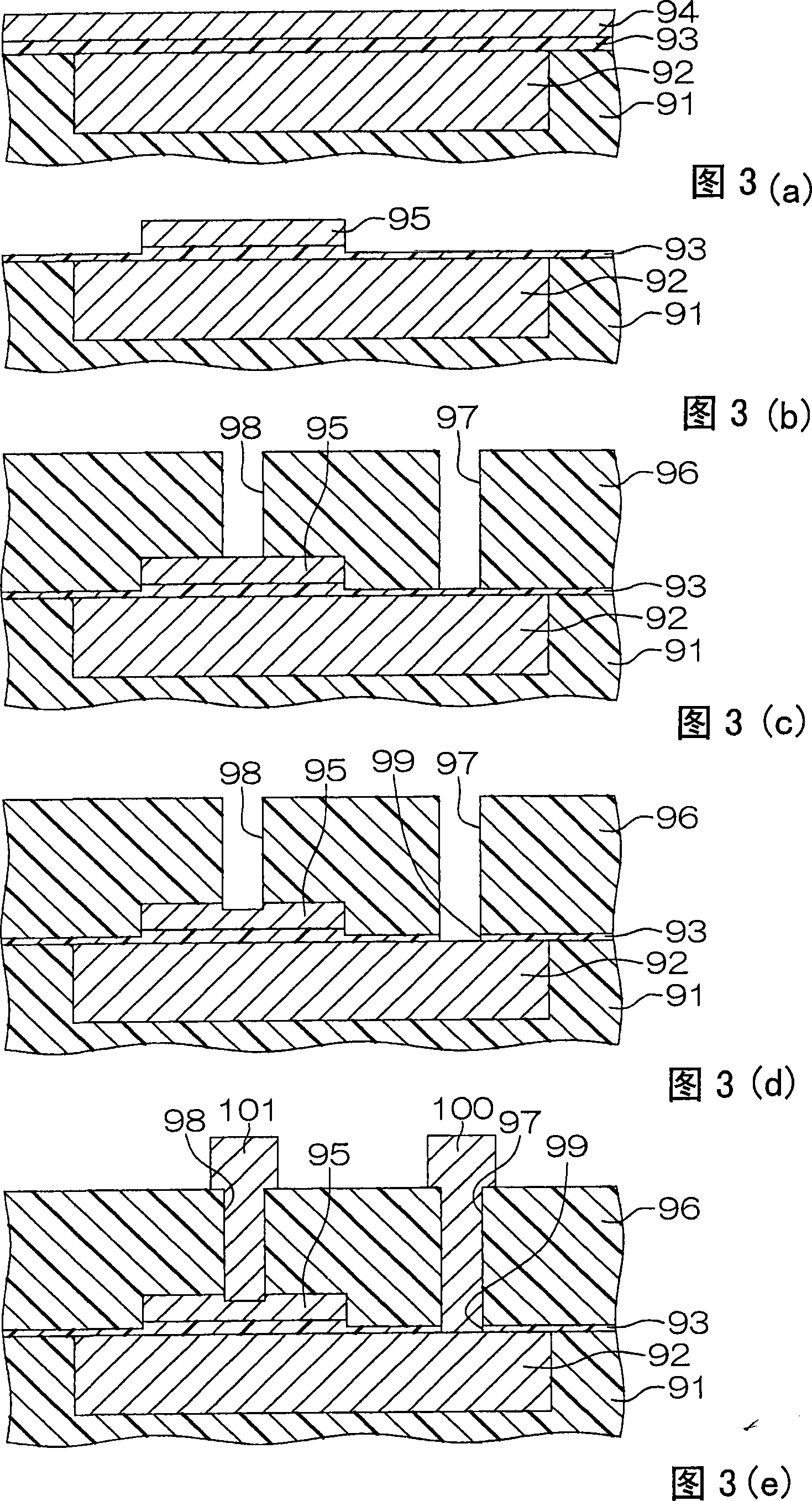

[0041] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

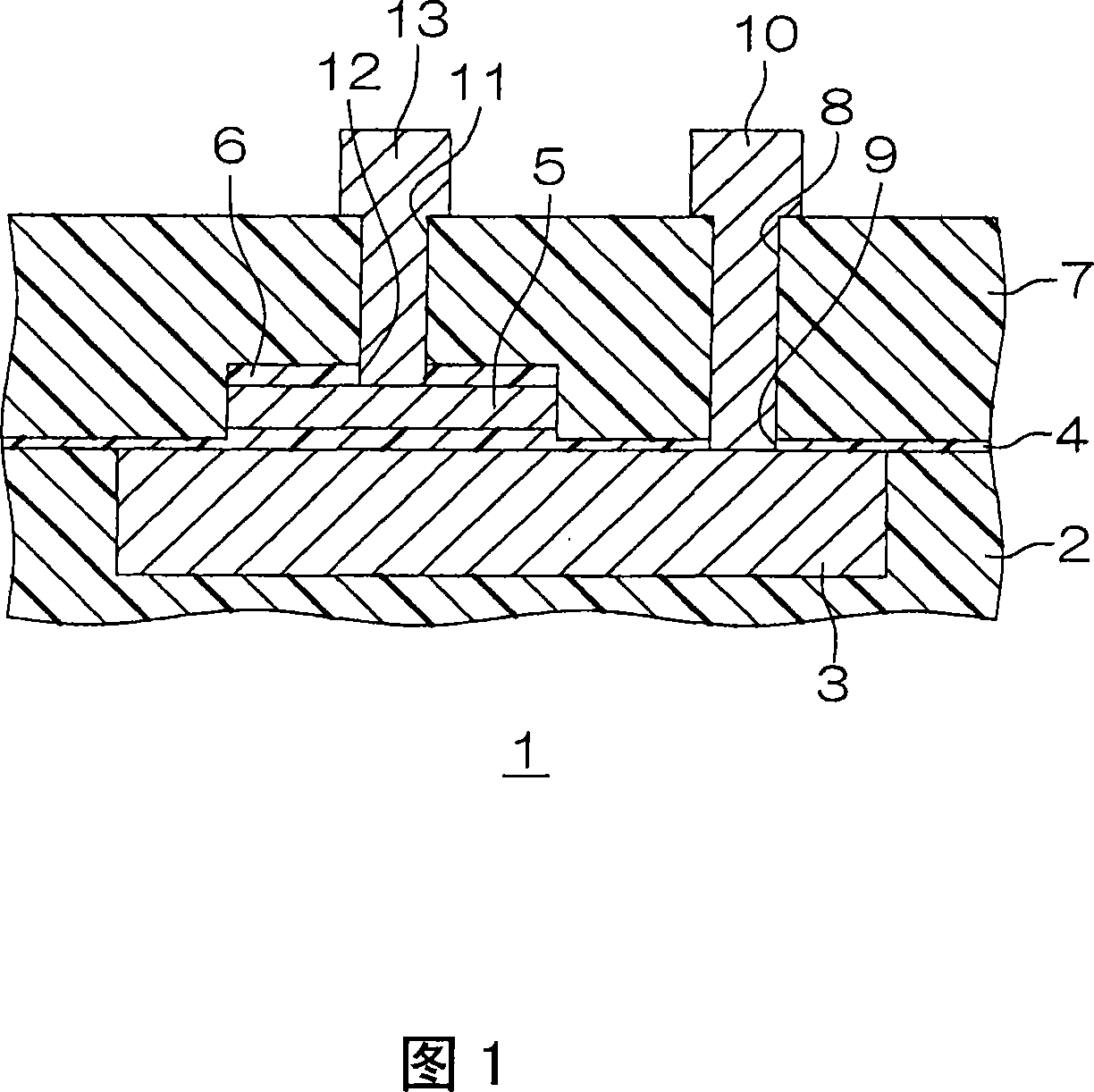

[0042] FIG. 1 is a cross-sectional view schematically showing the structure of a semiconductor device according to an embodiment of the present invention.

[0043] In this semiconductor device 1, a semiconductor substrate (not shown) mounted with a functional element such as a MOSFET (Metal Oxide Semiconductor Field Effect Transistor) made of SiO 2 (silicon oxide) interlayer insulating film 2. As the material of the interlayer insulating film 2 , for example, a Low-k film material such as SiOC (carbon-doped silicon oxide) or SiOF (fluorine-doped silicon oxide) may be used.

[0044] A lower electrode 3 made of Cu is embedded in the surface layer portion of the interlayer insulating film 2 . The surface of the lower electrode 3 is substantially flush with the surface of the interlayer insulating film 2 .

[0045] A capacitive film 4 made of SiN is laminated o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com