A Back-end Process for Improving the Reliability of Compound Semiconductor Devices

A technology of semiconductors and compounds, which is applied in the field of back section technology, can solve the problems of increasing device grounding resistance, large porosity at the edge of the hole, and process complexity, etc., and achieve the effect of reducing grounding resistance, reducing process cost, and simple equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

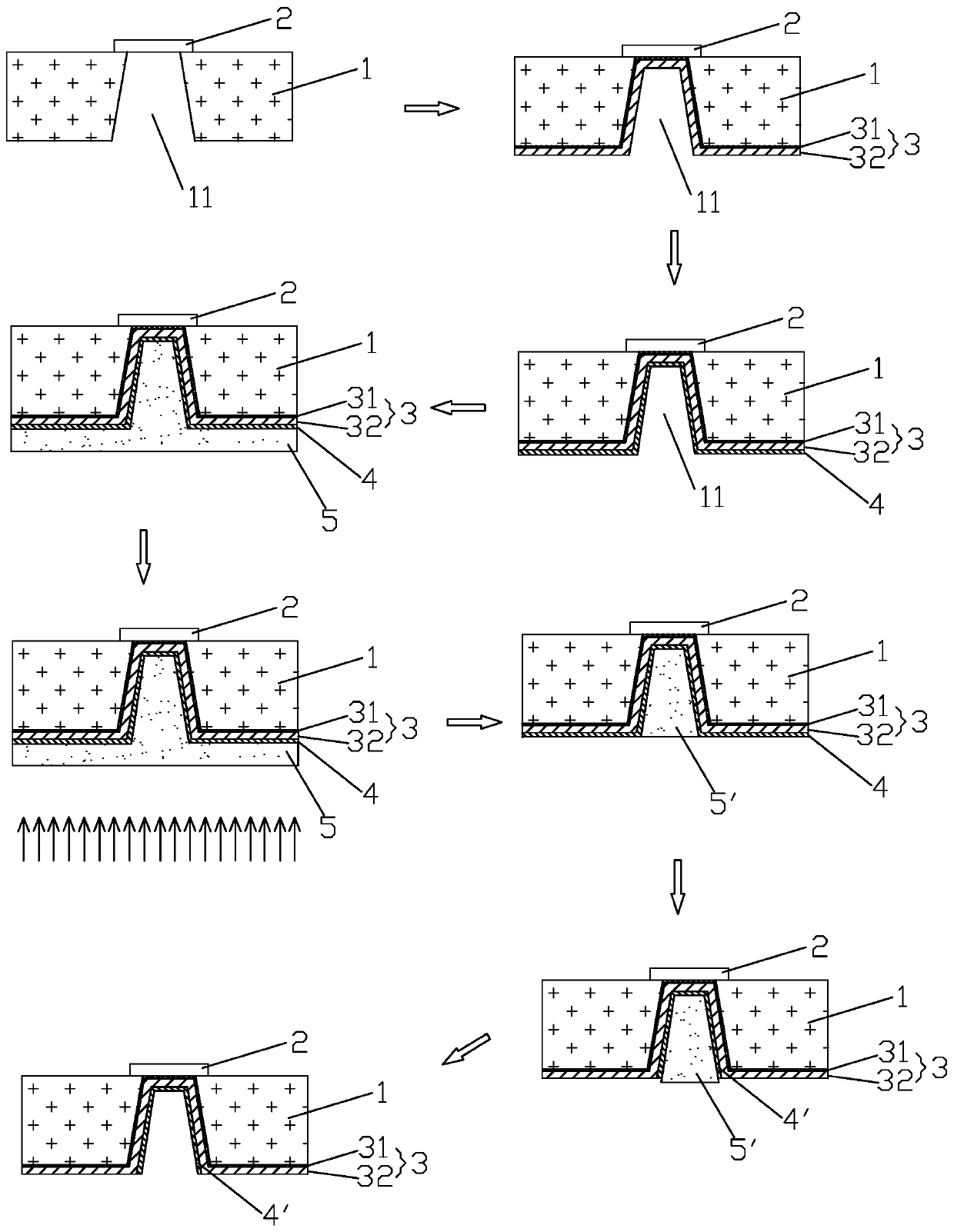

[0029] refer to figure 1 , a back-stage process for improving the reliability performance of a compound semiconductor device includes the following steps:

[0030] Step 1: Provide a compound semiconductor wafer 1 that has completed part of the device manufacturing process. The front side of the wafer 1 is provided with a metal wiring layer 2. The wafer 1 has a back hole 11 that runs through the front side and the back side. The back hole 11 exposes the Metal connection layer 2. Specifically, the wafer 1 can be a GaN or SiC wafer, and the front-side process of the device is completed, including device isolation, ohmic contact, gate metal, interconnection metal, final passivation layer, etc., so that a metal wiring layer 2 is provided on the front side; the back-side process of the device is completed , including bonding, thinning, via etching,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com