Method for processing precision patterns

A pattern and precise technology, applied in the field of manufacturing process, can solve problems such as unreachable, and achieve the effect of simplifying the degree of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

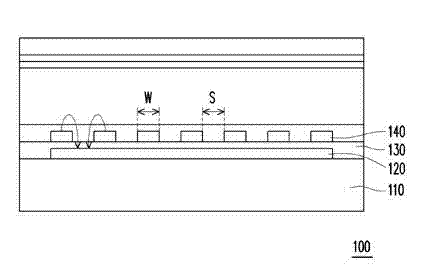

[0022] Generally speaking, when the lithographic etching process is carried out through the exposure machine, it may be limited by the design of the machine itself or the optical limitation of the exposure conditions, so the line width and spacing of the formed pattern will be limited. In this way, if it is desired to design a pattern with higher fineness, it will be difficult, such as the structure and content described in the prior art. Based on this, an embodiment of the present invention proposes a process method, which can still produce patterns with finer line width and spacing under the exposure conditions of the original exposure machine. The description is as follows, wherein this embodiment is based on A plurality of transparent conductive patterns are formed as an example.

[0023] Figures 2A-7A It is a top view of a process flow of a manufacturing method according to an embodiment of the present invention, which is suitable for making a precise pattern, and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com