Outer pin-free wire holder packaging structure

A technology of lead frame and external pins, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve the problems of increasing packaging steps and production costs, pollution, uneven surfaces, etc., and achieve reduction of packaging steps and The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

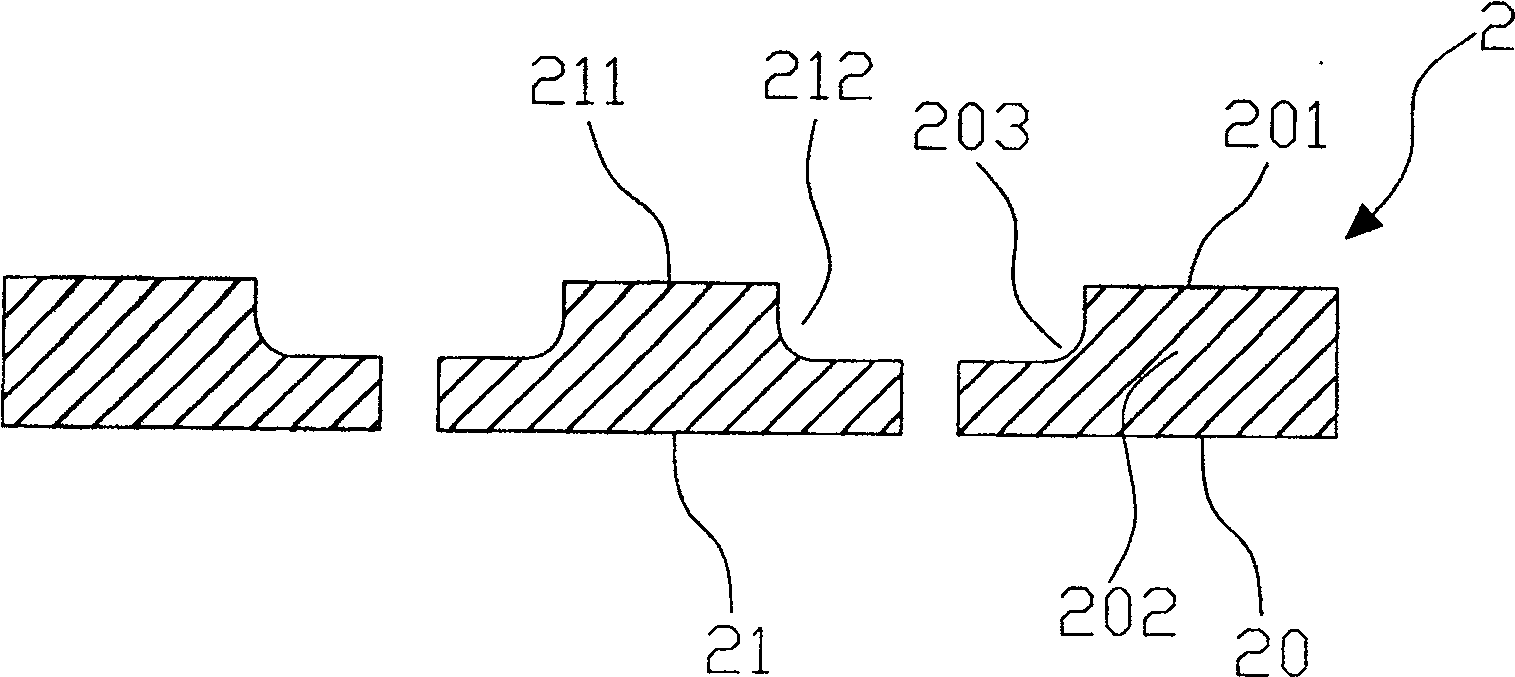

[0013] refer to figure 2 , which shows a schematic view of the first embodiment of the lead frame without outer leads of the present invention. The lead frame 2 of the first embodiment includes a frame 20 and a chip holder 21 . The frame 20 has a first surface 201 and a plurality of connecting portions 202 . The inner portion of the connecting portions 202 has a first concave portion 203 , and the first concave portion 203 is an arc angle. In this embodiment, the lead frame 2 is a four-sided flat lead frame without pins. In other applications, the lead frame 2 may also be a two-sided flat lead frame without pins.

[0014] The chip holder 21 is disposed in the frame 20 , the chip holder 21 has a crystal mounting surface 211 and a second concave portion 212 , and the second concave portion 212 is an arc angle. The die mounting surface 211 is located on the same plane as the first surface 201 of the frame 20 , and the second concave portion 212 is formed on a periphery of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com