Electric machine and baring structure thereof

A bearing and cushioning structure technology, applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of inner diameter reduction, contact with the rotating shaft 101, variation, etc., to reduce gap errors and overcome assembly errors , reduce the possible effects of shaking and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

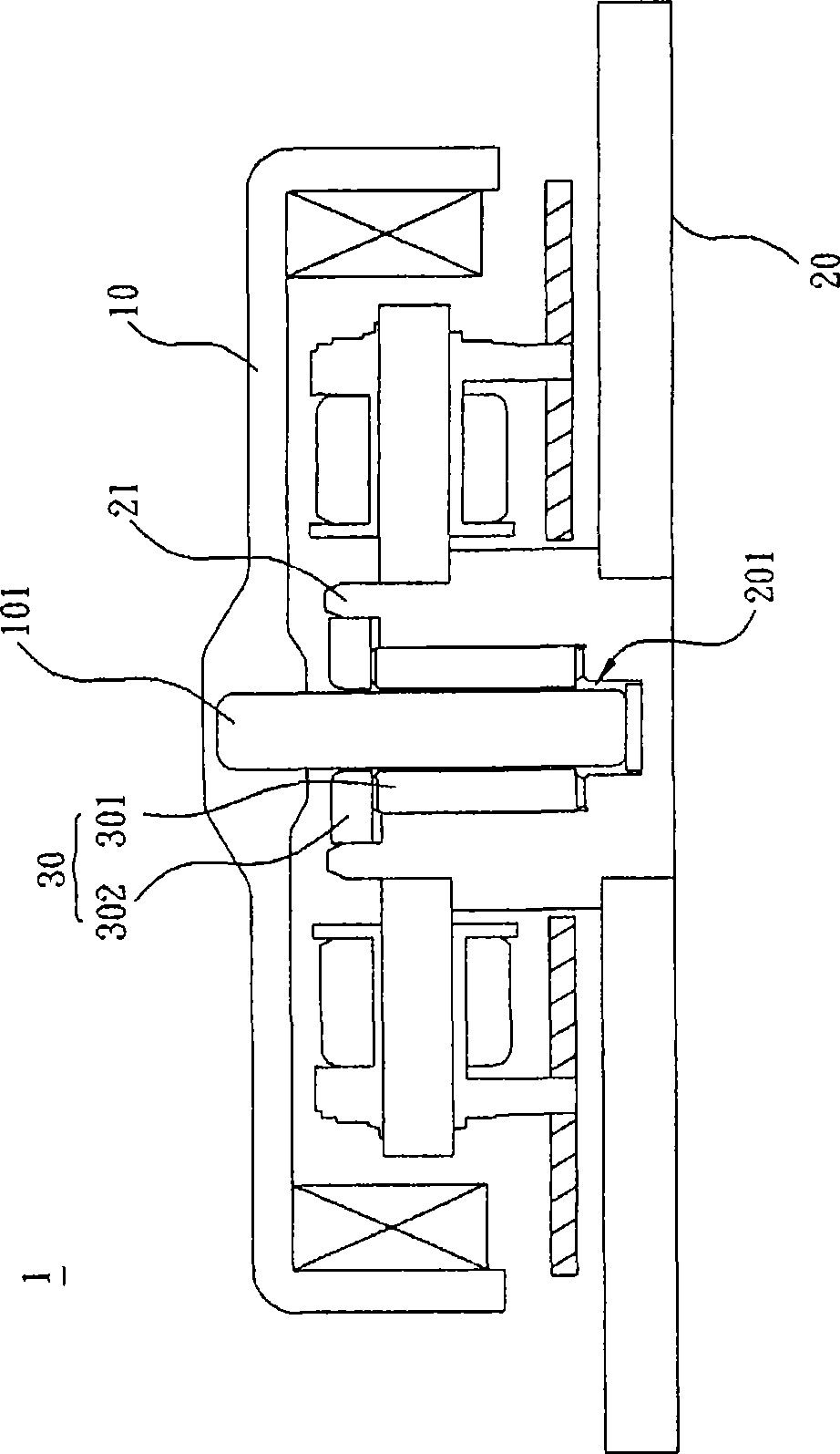

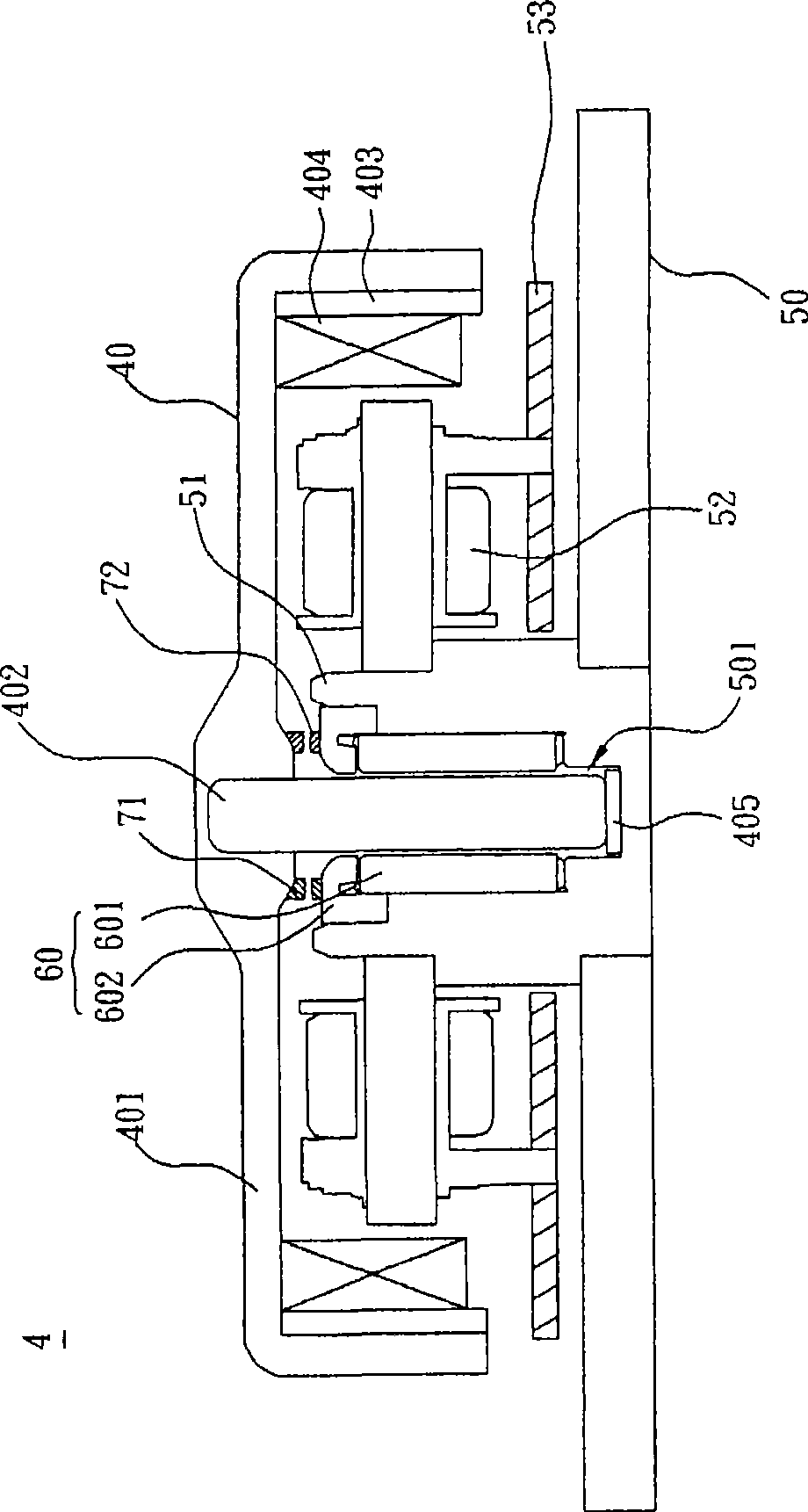

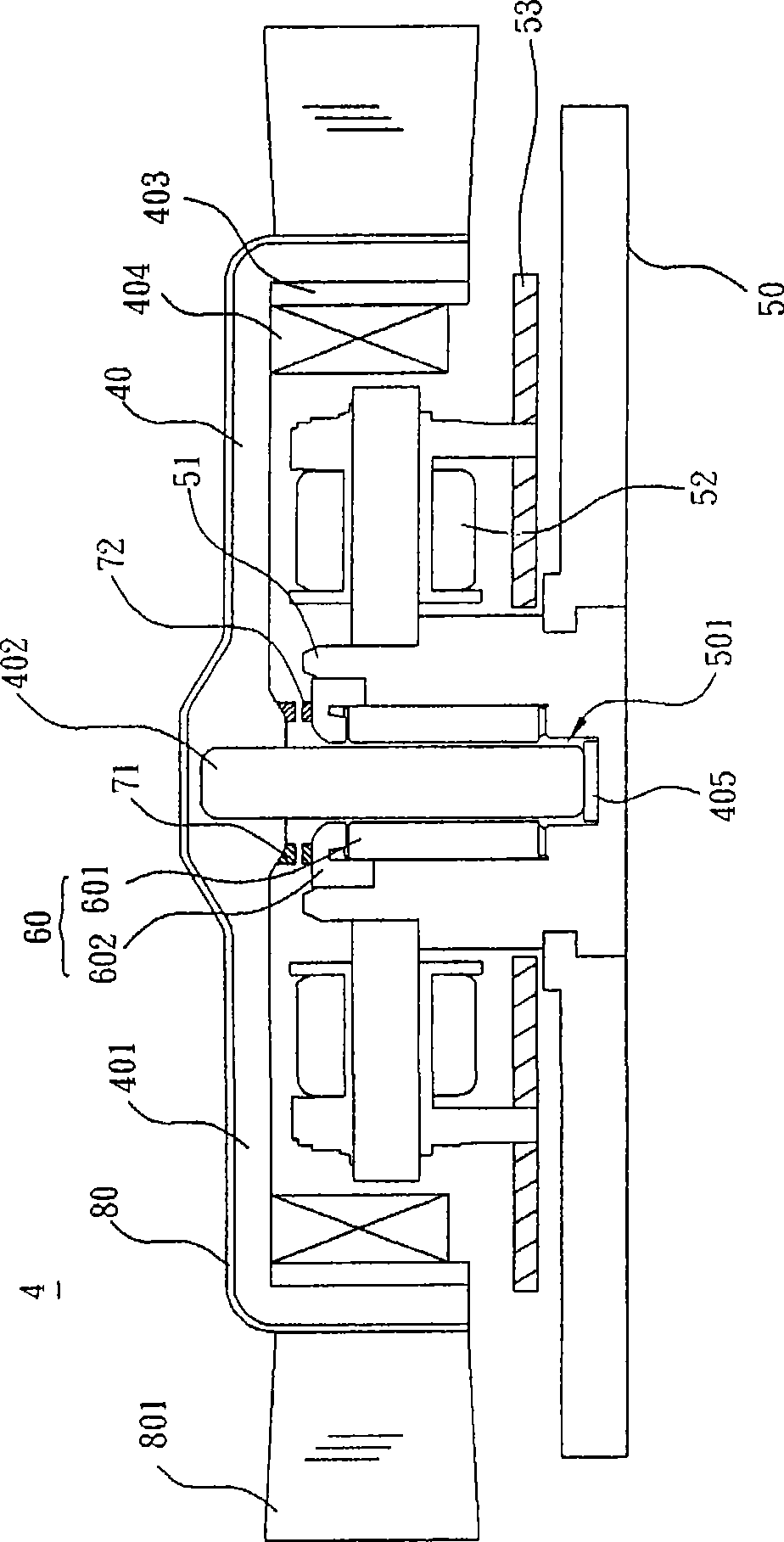

[0035] The motor and its bearing structure according to preferred embodiments of the present invention will be described below with reference to the relevant drawings, wherein the same elements will be described with the same reference symbols.

[0036] Please refer to figure 2 and image 3 As shown, the motor 4 according to the preferred embodiment of the present invention includes a rotor structure 40 , a stator structure 50 and a bearing structure 60 .

[0037] The rotor structure 40 includes a hub 401 and a shaft 402 , and the shaft 402 is connected to the hub 401 . Such as figure 2 As shown, the rotating shaft 402 is embedded in the hub 401 . In addition, the rotating shaft 402 and the hub 401 can also be integrally formed, that is, the rotating shaft 402 and the hub 401 form a single body.

[0038] As mentioned above, the inner surface of the hub 401 is sequentially fixed with a magnetically conductive shell 403 and a magnet 404 . Wherein, the magnetically conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com