Fast exchanging mechanism for clamping head

A collet and rotating sleeve technology, applied in the direction of clamping, metal processing mechanical parts, supports, etc., can solve the problems of unreliable prevention of disengagement, easy wear and failure, etc., to achieve reliable connection, convenient installation and disassembly, operation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

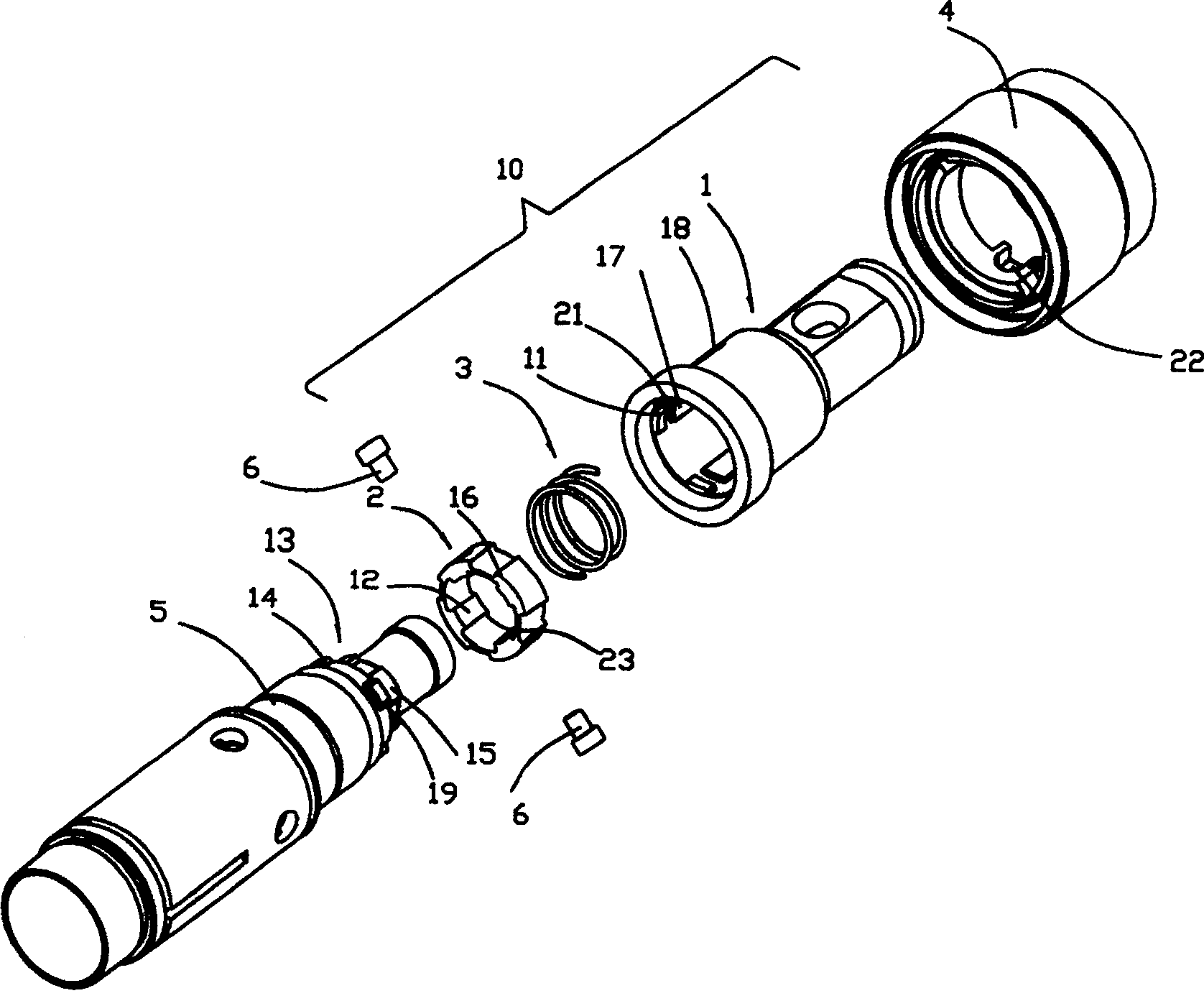

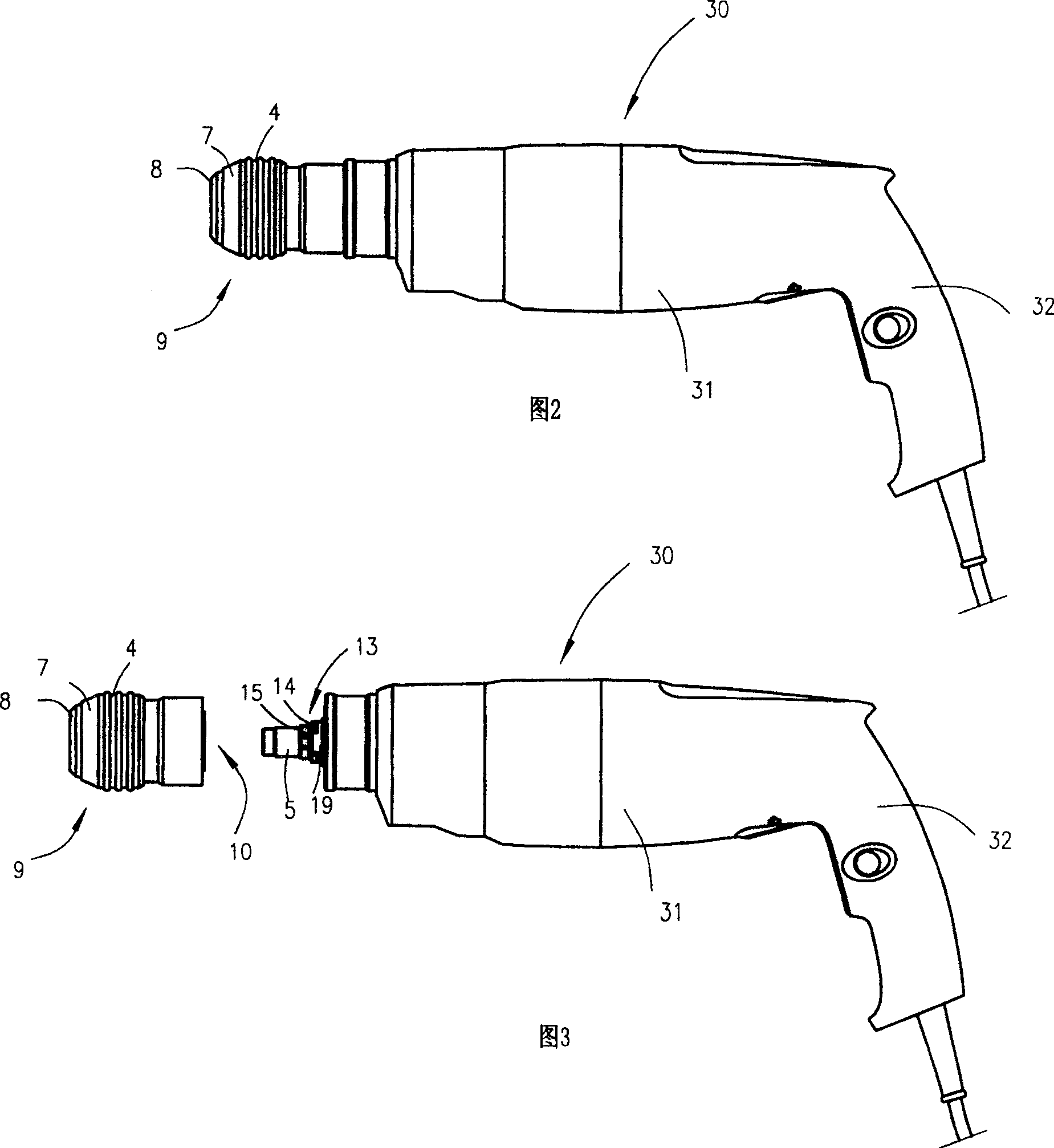

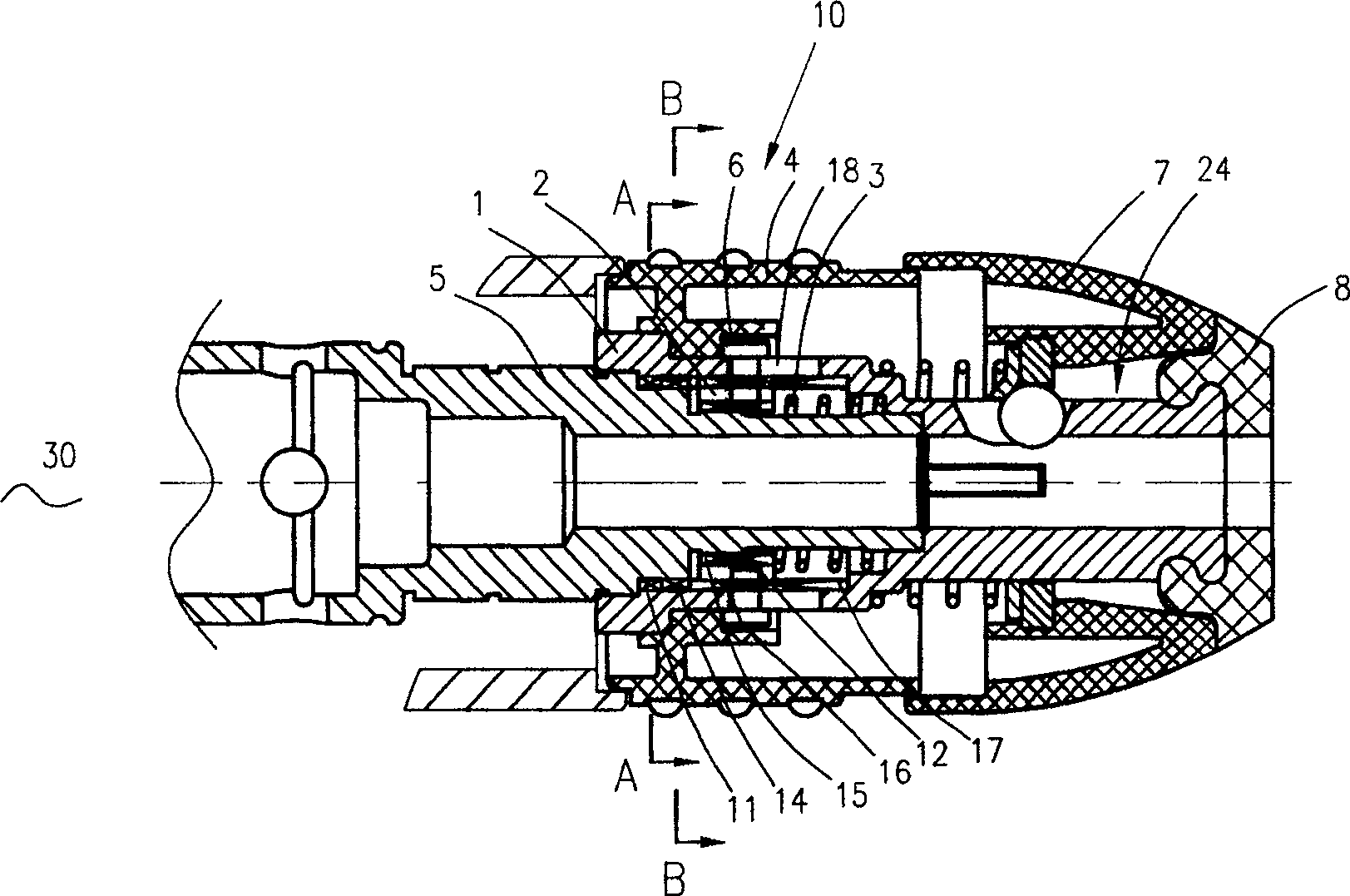

[0021] See attached Figure 1~3 , the present invention discloses a chuck quick change mechanism 10 . The collet quick change mechanism 10 detachably installs the collet 9 on the main shaft 5 of the electric tool 30 . The electric tool 30 includes a tool body 31 , a handle 32 located at the rear of the tool body 31 , a drive unit and a transmission unit (not shown) accommodated inside the tool body 31 , and a spindle 5 connected to the transmission unit. In the present invention, the electric tool 30 is an electric hammer.

[0022] The main shaft 5 includes an inner surface and an outer surface. Wherein the outer surface is provided with a positioning piece 13 and a first groove 19 . In this preferred embodiment, the positioning member 13 includes a first external spline 14 and a second external spline 15 , and the outer diameter of the first external spline 14 is larger than the outer diameter of the second external spline 15 . The first groove 19 is located on the side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com