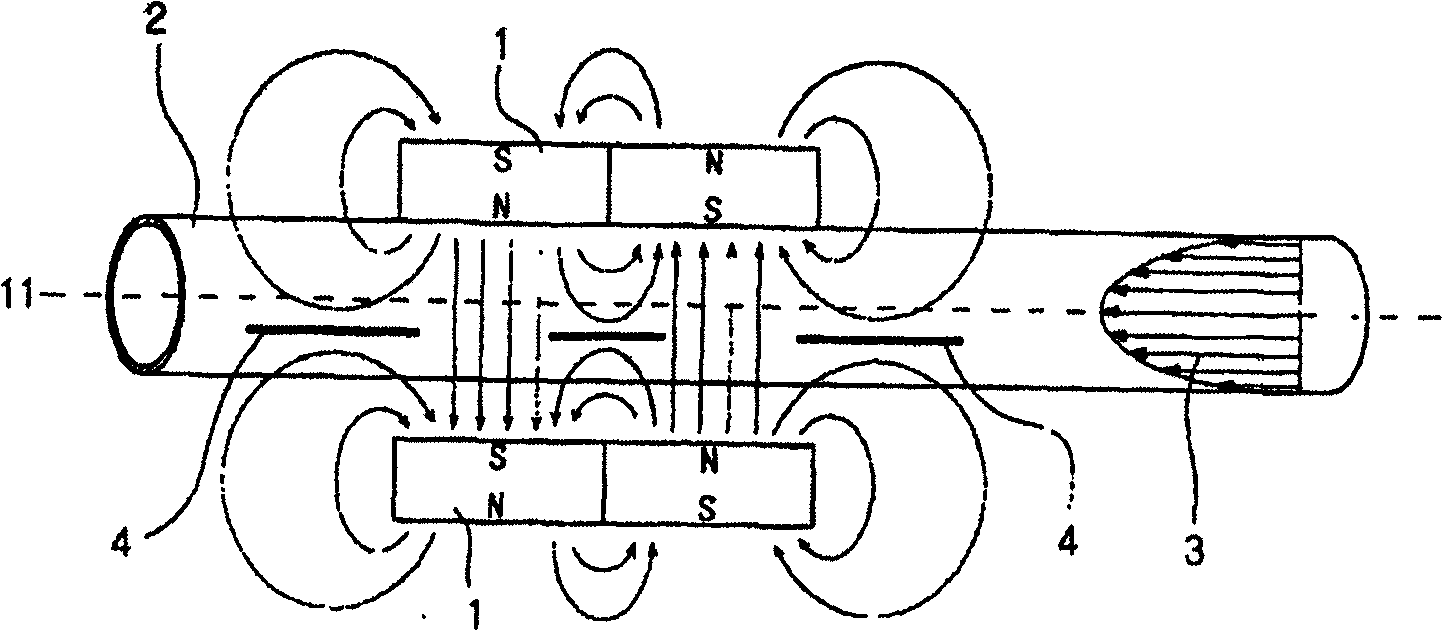

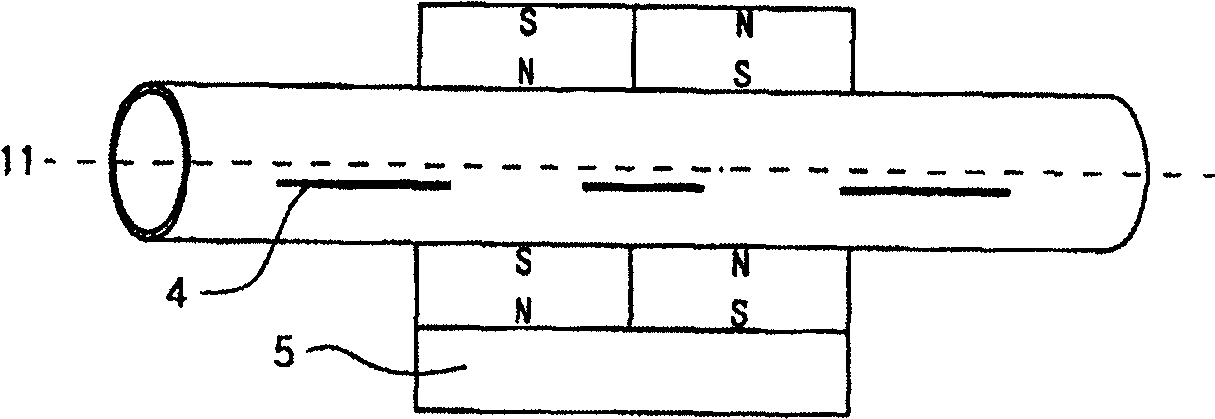

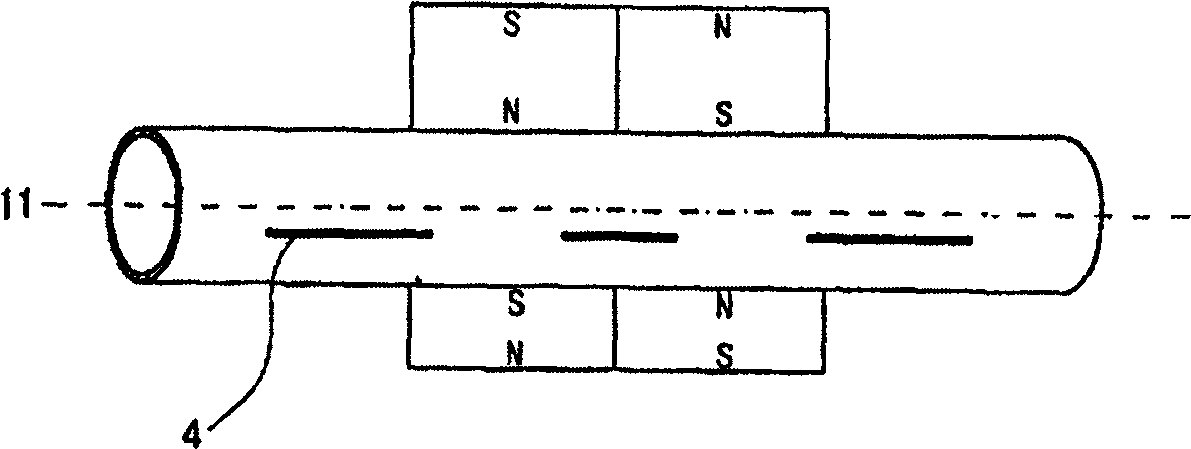

Apparatus for fluid or gas magnetization

A magnetization device and liquid technology, which is applied in the direction of charging system, combustion air/combustion-air treatment, engine components, etc., can solve the problem of leakage of liquid or gas from magnetization devices and liquid or gas pipelines, difficulty in installing magnetization devices, and Gauss intensity Growth and other issues, to achieve the effect of increasing fuel mileage, reducing air pollution, and reducing particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] For the Sonata III type car (engine displacement: 1,836cc; fuel: gasoline; automatic transmission) manufactured by Hyundai Engine Company of South Korea, under the condition that no magnetization device is installed and the driving mileage is 45,617km, the exhaust gas concentration and fuel consumption rate are measured; Under the same model and the same method, under the condition that the magnetization device is installed and the travel distance is 100km, the exhaust gas concentration and fuel consumption rate are measured. The test results are shown in Table 1 below

[0045] Table 1: Exhaust concentration and fuel consumption rate tested under test item CVS-75 (FTP-75) mode

[0046]

example 2

[0048] Measure the particulate matter and Output power: Under the same vehicle model and the same method, under the condition of installing a magnetization device and traveling from 10,000km to 128,770km, the particulate matter in the exhaust gas and the output power are measured. The results are shown in Table 2 below

[0049] Table 2: Testing of Exhaust Loads in Automotive Precision Tests

[0050]

[0051] It can be seen from the above table that in diesel locomotives, due to the magnetization of liquid or gas, the fuel consumption rate is reduced and the particulate matter is also significantly reduced, and from the values in Table 2, it can be seen that under the first mode and the second mode Particulate matter is reduced by almost 50%, and in third mode it is reduced by almost 30%, so there is a significant reduction in particulate matter unevenness, and the output power of the car is also increased by almost 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com