An electrical connector

A technology of electrical connectors and electrical connection devices, which is applied in the direction of connections, circuits, and parts of connection devices, etc., which can solve the problems that screws and spring washers do not have electrical characteristics, and achieve the effect of easy assembly and low cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

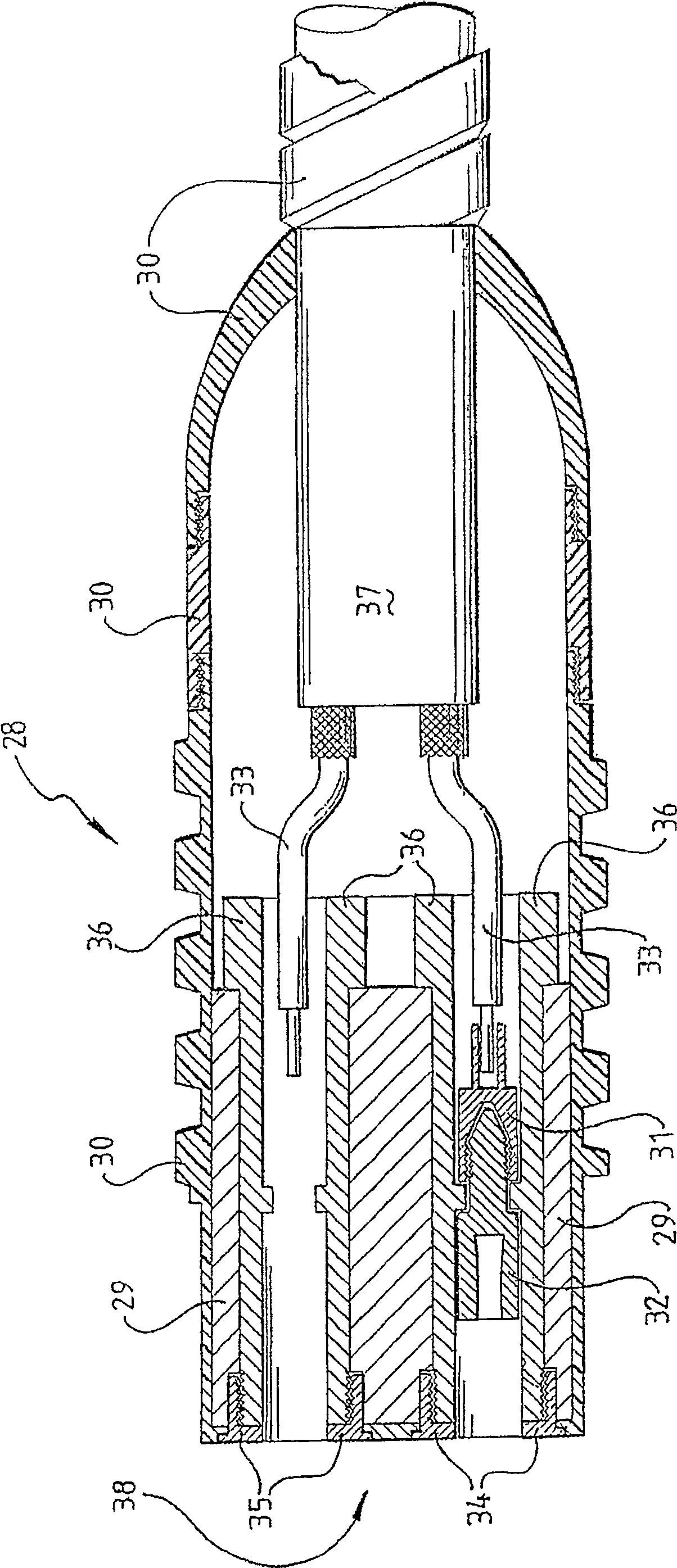

[0033] see image 3 , detailing a socket including an electrical connector according to a specific embodiment. The plug connector 28 includes a socket 32 and a connector 31 . In this embodiment, the socket 32 and the joint 31 are each integrally formed. The connector 31 is connected to the core 33 of the machine cable 37 . The receptacle 32 is adapted to accept a plug (not shown) and has a threaded post portion which interlocks with the threaded hole of the fitting 31 .

[0034] The plug connector 28 includes an approximately cylindrical body 29 and a housing 30 made of metal and / or insulating material. The socket 28 has an end face 38 in which there are three holes defined by nuts such as nuts 34 and 35 . An insulating sleeve 36 protrudes toward the inside of each hole. The joint 31 has a key (not shown), and the sleeve 36 has a corresponding keyway (not shown), thereby restricting the rotation of the joint 31 in the sleeve 36 and simplifying the connection of the soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com