A kind of preparation method of lithium aluminate/lithium carbonate coating NCA cathode material

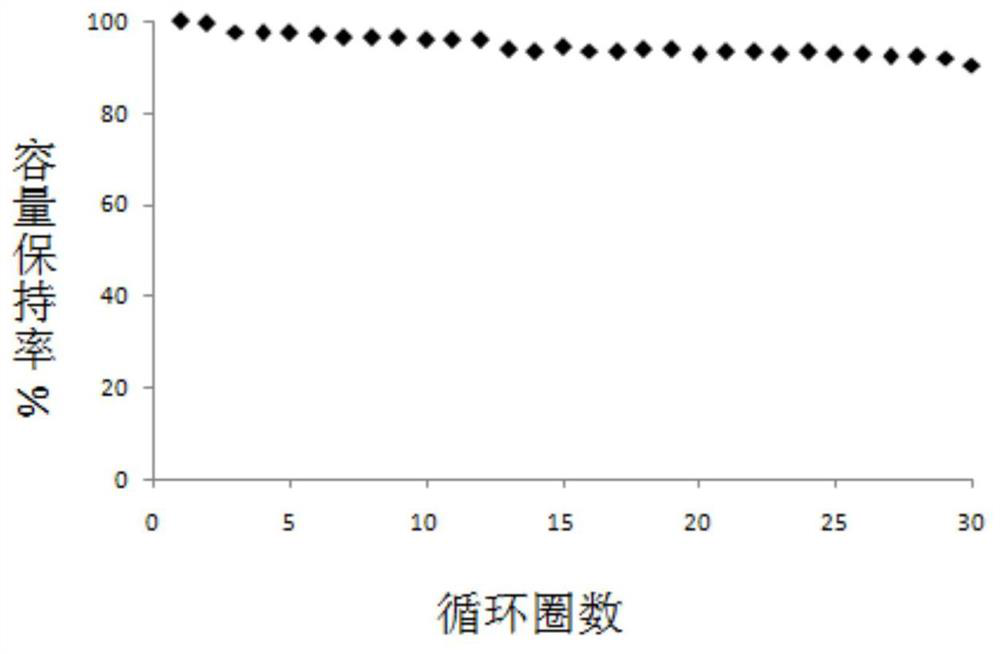

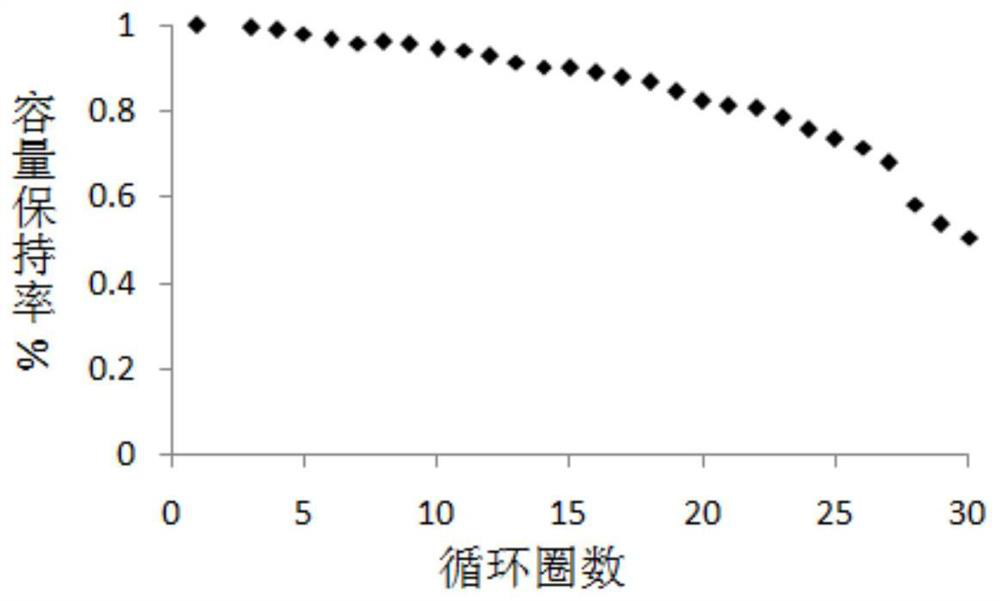

A cathode material and coating technology, which is applied in the field of preparation of lithium aluminate/lithium carbonate coated NCA cathode material, can solve the problems of complex coating process, cumbersome method and high preparation cost, achieve good ion conductivity, improve Rate performance, the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A LiAlO 2 / Li 2 CO 3 The preparation method of coated NCA cathode material comprises the steps:

[0025] (1) Prepare to weigh organic lithium salt and organic aluminum salt, and dissolve the two in ethanol solution to prepare mixed ethanol solution;

[0026] (2) In an argon environment, add the NCA ternary material powder to the mixed ethanol solution obtained in step (1), ultrasonically treat it for 30 minutes, and then dry it in vacuum;

[0027] (3) Heating the product obtained in step (2) to 300°C, calcining at this temperature for 2 hours, and then grinding to obtain;

[0028] The organoaluminum salt is aluminum isopropoxide;

[0029] The organic lithium salt is lithium ethylate;

[0030] The NCA ternary material is LiNi 0.8 co 0.1 5Al 0.05 o 2 ;

[0031] The mass fraction of organoaluminum salt in the mixed ethanol solution is 1%;

[0032] The mass fraction of organolithium salt in the mixed ethanol solution is 1%;

[0033] The heating rate is 1°C / min. ...

Embodiment 2

[0035] A LiAlO 2 / Li 2 CO 3 The preparation method of coated NCA cathode material comprises the steps:

[0036] (1) Prepare to weigh organic lithium salt and organic aluminum salt, and dissolve the two in ethanol solution to prepare mixed ethanol solution;

[0037] (2) In a neon gas environment, add NCA ternary material powder to the mixed ethanol solution obtained in step (1), ultrasonically treat for 180min, and then vacuum dry;

[0038] (3) Heating the product obtained in step (2) to 300°C, calcining at this temperature for 5 hours, and then grinding to obtain;

[0039] The organoaluminum salt is aluminum propoxide;

[0040] The organic lithium salt is lithium propoxide;

[0041] The NCA ternary material is LiNi 0.8 co 0.1 5Al 0.05 o 2 ;

[0042] The mass fraction of organoaluminum salt in the mixed ethanol solution is 10%;

[0043] The mass fraction of organolithium salt in the mixed ethanol solution is 10%;

[0044] The heating rate is 15°C / min.

Embodiment 3

[0046] A LiAlO 2 / Li 2 CO 3 The preparation method of coated NCA cathode material comprises the steps:

[0047] (1) Prepare to weigh organic lithium salt and organic aluminum salt, and dissolve the two in ethanol solution to prepare mixed ethanol solution;

[0048] (2) In a xenon environment, add the NCA ternary material powder to the mixed ethanol solution obtained in step (1), ultrasonically treat it for 90 minutes, and then dry it in vacuum;

[0049] (3) Heating the product obtained in step (2) to 300°C, calcining at this temperature for 3.5 hours, and then grinding to obtain;

[0050] The organoaluminum salt is aluminum ethylate;

[0051] The organic lithium salt is a mixture of lithium ethylate and lithium propoxide;

[0052] The NCA ternary material is LiNi 0.8 co 0.1 5Al 0.05 o2 ;

[0053] The mass fraction of organoaluminum salt in the mixed ethanol solution is 5%;

[0054] The mass fraction of organolithium salt in the mixed ethanol solution is 5%;

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com