Method for locally highly doped and connected semiconductor structures that are solar cells or precursors to solar cells

A technology of solar cells and semiconductors, applied in semiconductor devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as high cost and impracticality, and achieve the effects of improving light efficiency, reducing total contact resistance, and reducing surface recombination speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

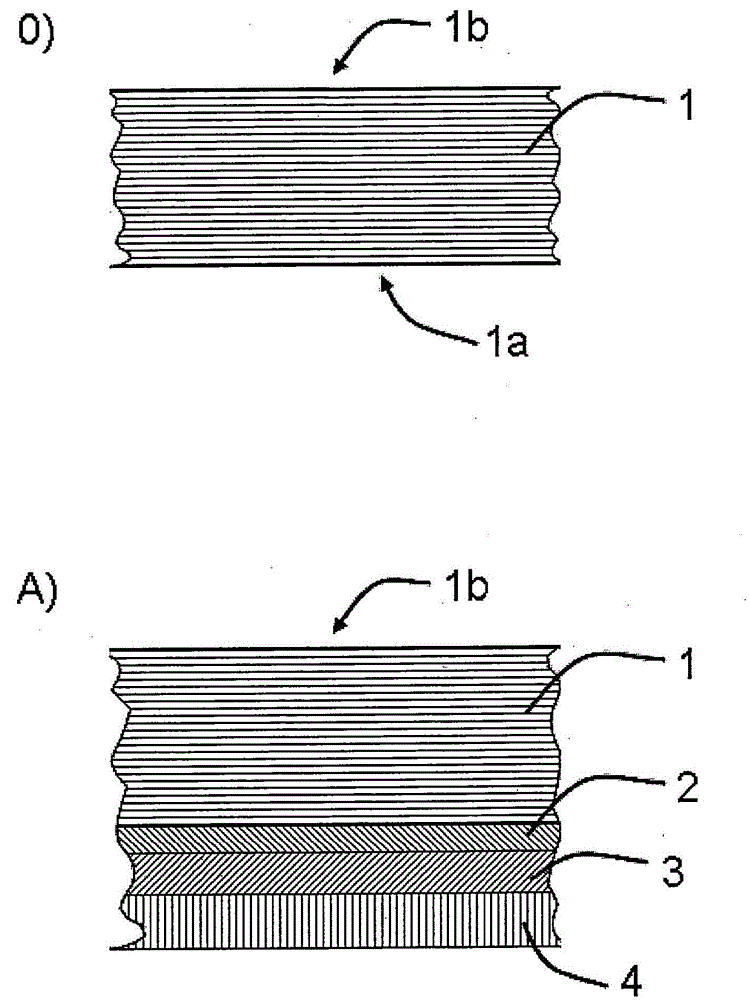

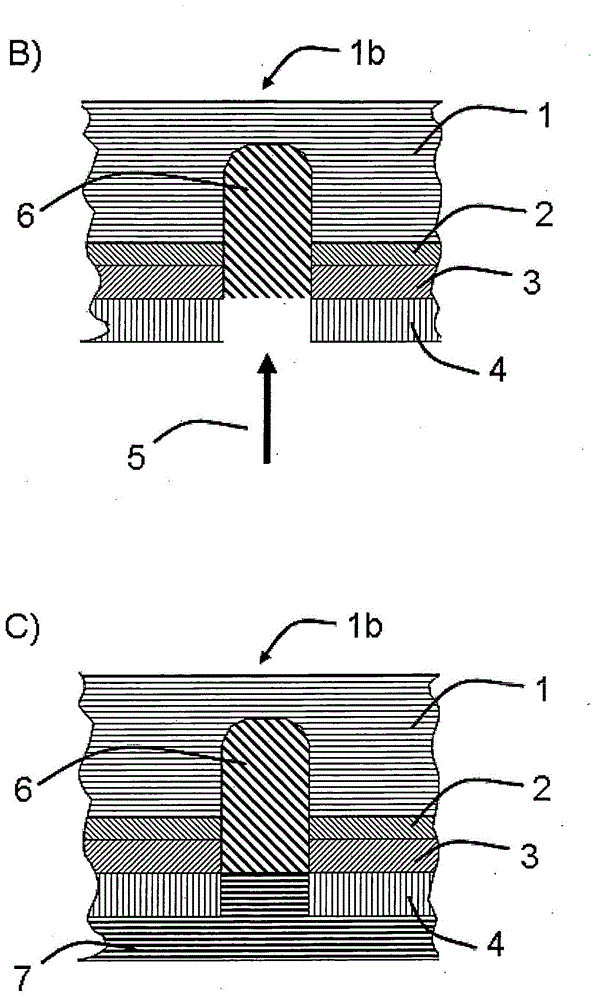

[0052] exist figure 1 and 2 An exemplary embodiment of the method according to the invention for locally highly doping and switching on a semiconductor structure which is a silicon solar cell precursor is shown in . The same reference numerals are used to denote the same elements throughout the drawings.

[0053] The semiconductor substrate 1 in the form of a silicon wafer has a uniform doping with a dopant concentration of 5×10 15 cm −3 . The solar cells to be produced are therefore n-type silicon solar cells.

[0054] In all the schematic diagrams shown in the figures, only a section of a semiconductor structure is shown, which respectively extends to the left and to the right. For better illustration, the diagrams are not shown to scale, especially with respect to the ratio of height and width.

[0055] The semiconductor substrate 1 has a contact surface 1 a, which is the rear side of the semiconductor substrate. In the completed solar cell, during operation, the semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com