Spheriodizing technique for preventing Mg from fireless and floating in nodular cast iron production

A ball milled cast iron and spheroidizing technology, which is applied in the floating spheroidizing process to prevent the burning of effective element magnesium in the spheroidizing agent, can solve the problem that the formation of spherical graphite cannot be effectively controlled, the burning loss of spheroidizing element magnesium cannot be determined, and the problem of molten iron pellets In order to avoid problems such as different quality of spheroidization, achieve the effect of fast dissolution and diffusion, reduce the probability of spheroidization decline, and improve the pass rate of spheroidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

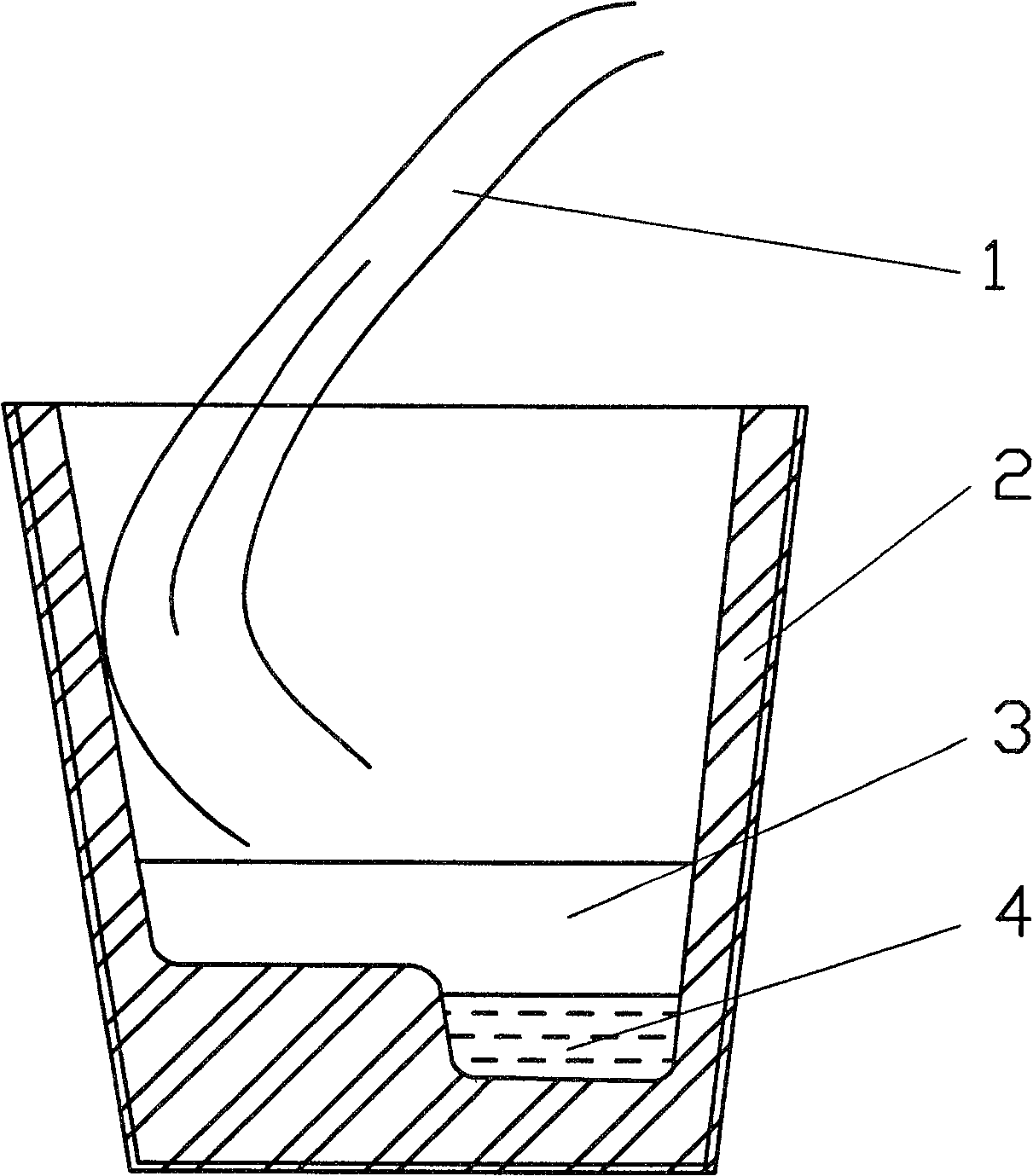

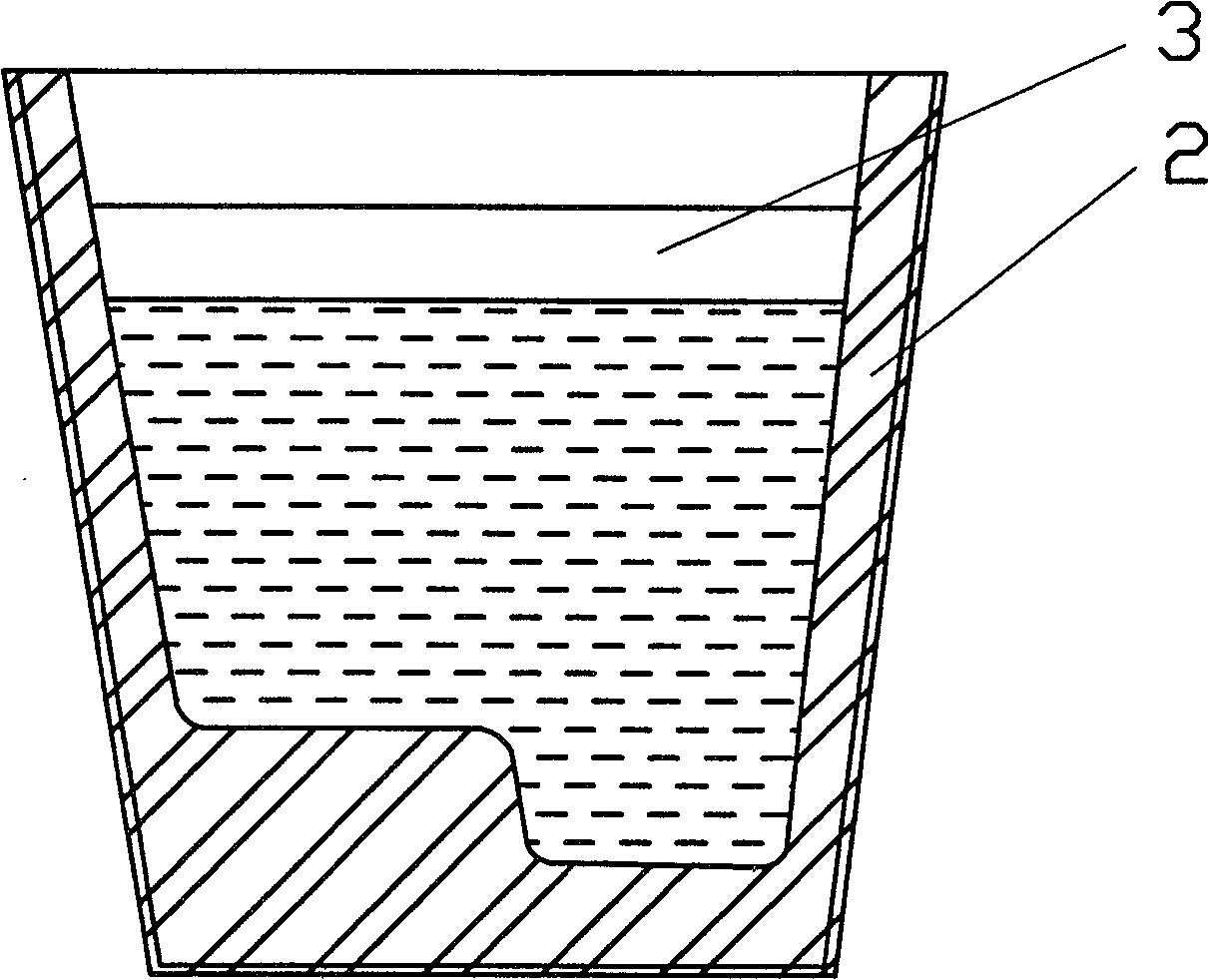

[0023] see figure 1 with figure 2 , preheat the spheroidizing treatment bag 2 to above 800 degrees, pass carbon dioxide gas 3 to the bottom of the spheroidizing treatment bag 2, remove the air, add the spheroidizing agent, and form a carbon dioxide gas protective film around the spheroidizing agent. After the magnesium in the agent is completely melted to form a magnesium melt 4, the molten iron 1 is added to the spheroidizing treatment bag 2, and the spheroidizing process of the molten iron is completed.

[0024] Argon gas can also be fed into the bottom of the spheroidization treatment bag 2 as a protective gas.

[0025] In the case of no special equipment or special process, pure magnesium is used as nodulizer to directly spheroidize molten iron.

[0026] Since magnesium is isolated from the air under the action of a protective film of reducing gases such as carbon dioxide or inert gases, magnesium will not burn. Since molten iron and molten magnesium are two metal liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com