Multifunctional friction hoisting antiskid experimental device and method

A technology of friction lifting and experimental equipment, which is applied in the sliding rope experiment to study the mechanism of friction lifting sliding rope and the detection and elimination of sliding fields. It can solve the problems of unsafe, inconvenient operation, time-consuming, etc., and achieve easy installation and operation, and eliminate sliding failure, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

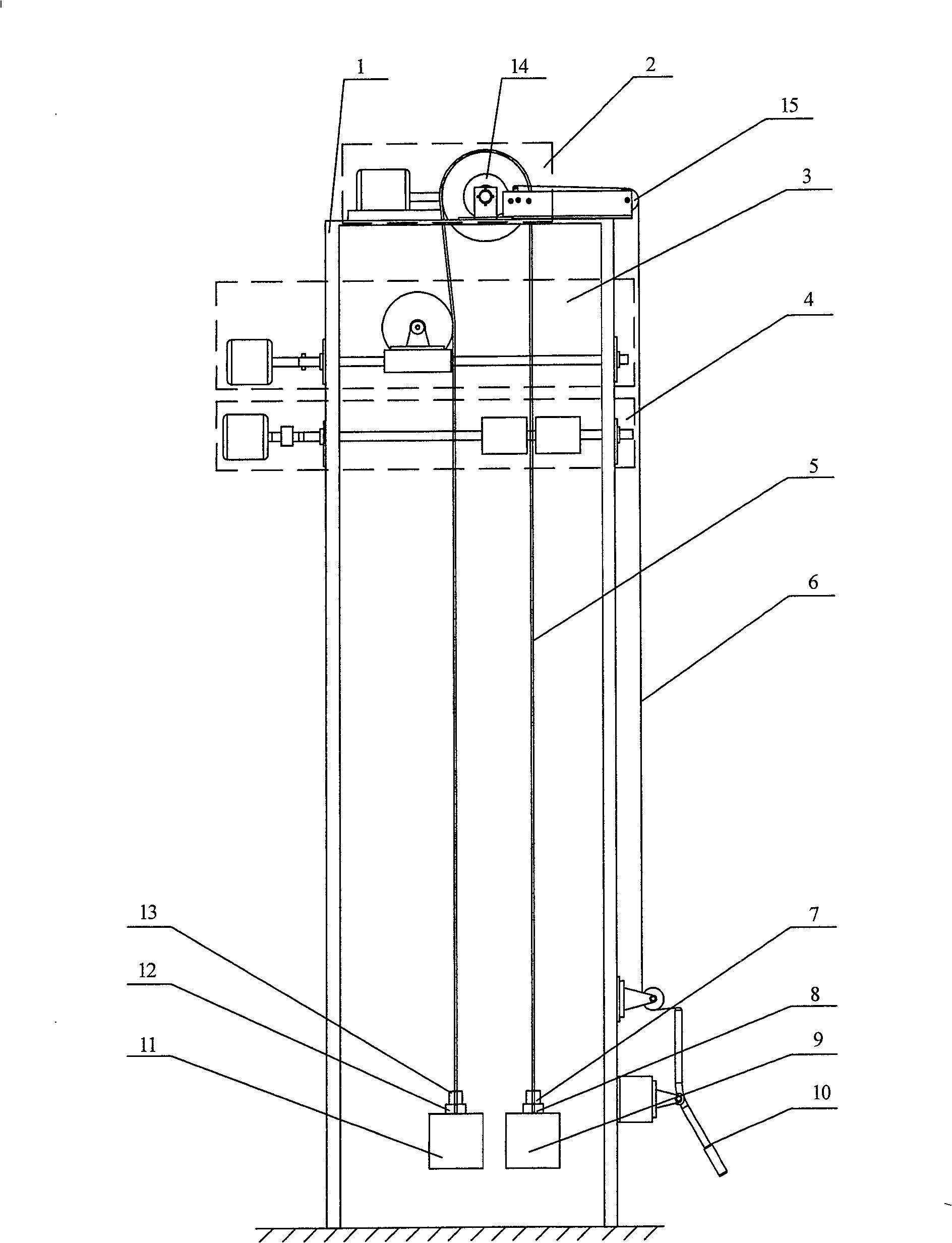

[0014] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

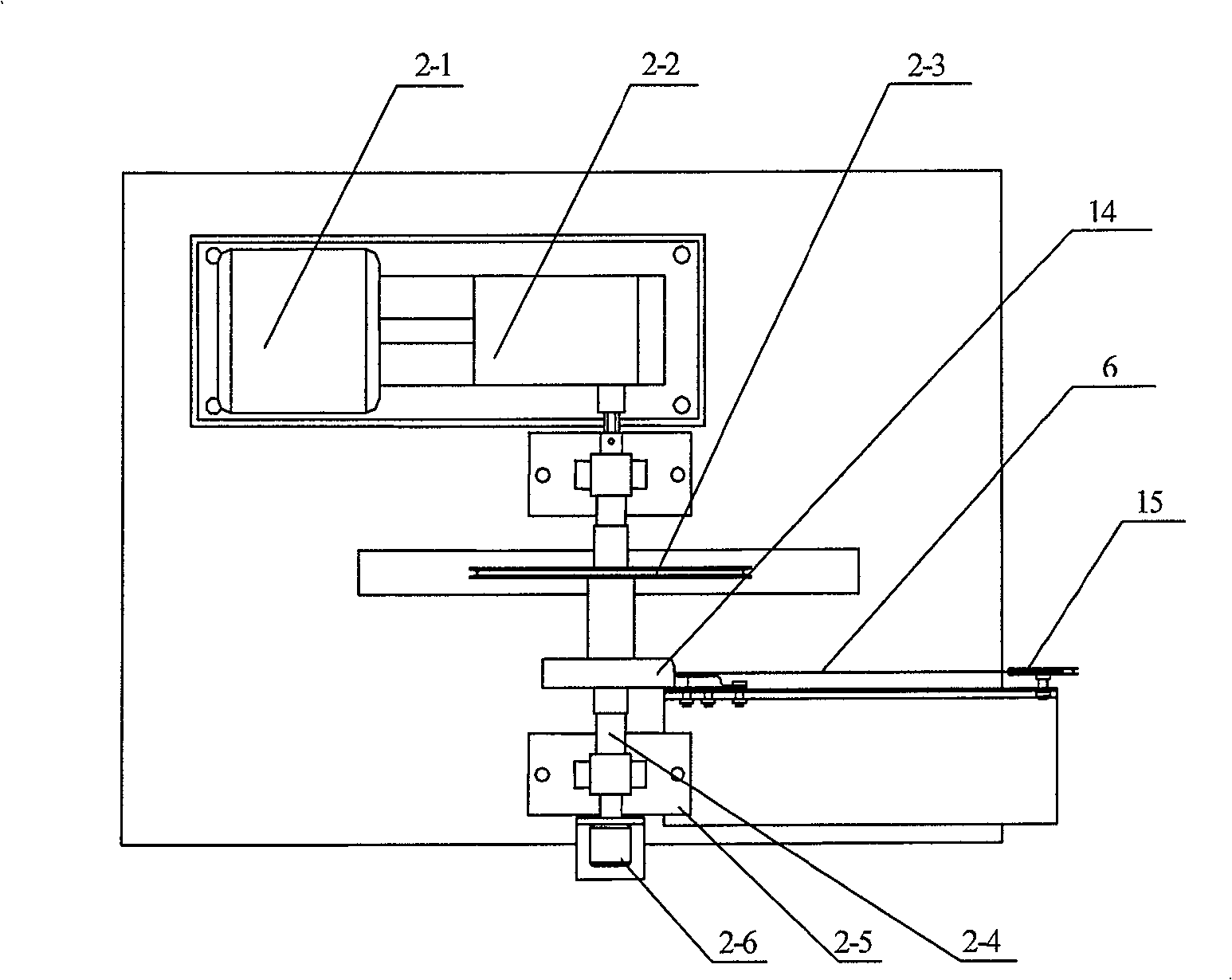

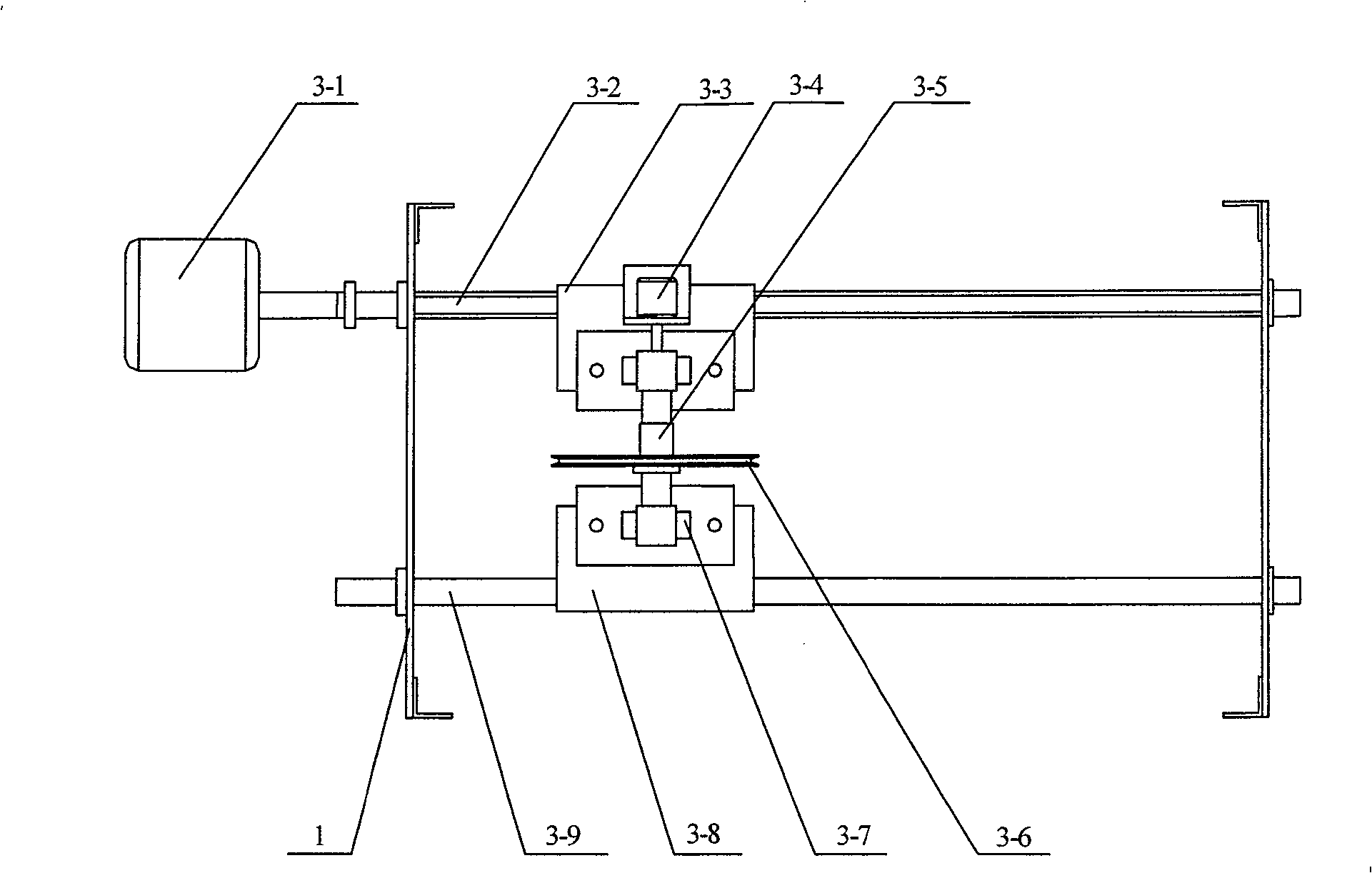

[0015] figure 1 As shown, the friction lifting anti-skid experimental device is composed of a frame 1, a power device 2, a guide device 3, a tension adjustment device 4, a brake device, a loading device 9, 11, and a detection and control device. The frame 1 is welded or riveted by section steel and steel plate to form a derrick type rigid structure, and other devices are all fixed on it according to certain space requirements. Loading devices 9, 11 are containers with different weights that can be added. Loading devices 9, 11 are hung on the friction wheel 2-3 of power unit 2 through steel wire rope 5. Loading devices 9, 11 and steel wire rope 5 are connected. Tension sensors 7, 13 and acceleration sensors 8, 12 connected with the control device. The braking device mainly brakes the power unit 2. It consists of a brake disc 14 on the same shaft as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com