Pressed-film ultra-hard material synthesizer

A technology of superhard material and synthesis equipment, which is applied in the field of pressure mode superhard material synthesis equipment, can solve the problems of poor stability of diamond synthesis pressure, poor spatial position accuracy of six-cylinder piston, and high cost of synthesis equipment, and achieves stable and controllable type. Good performance, good pressure stability, good coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

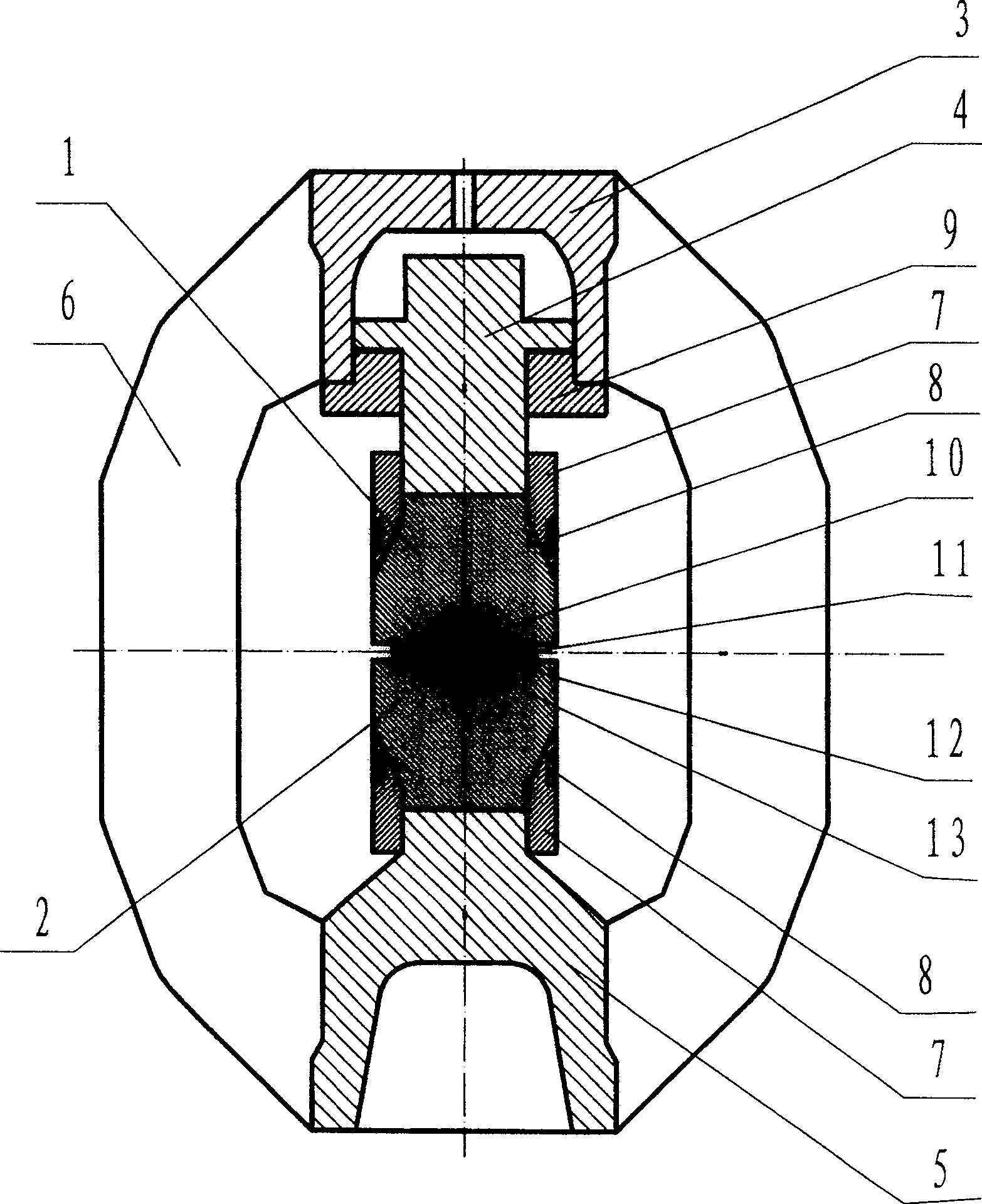

[0014] Compression mode superhard material synthesis equipment, including the upper mold 1 of the synthesis cavity and the lower mold 2 of the synthesis cavity correspondingly provided with a hemispherical groove in the central part, the distal part of the upper mold 1 of the synthesis cavity and the piston 4 in the piston cylinder 3 of the power source Axially fixedly connected, the distal end of the synthetic cavity lower mold 2 is axially fixedly connected to the top of the lower support body 5 of the press, and the power source piston 4 is connected to the side of the lower support body 5 of the press through a connection frame 6 .

[0015] The upper mold 1 and the lower mold 2 of the composite cavity are composed of a small cylindrical section, a truncated cone section and a large cylindrical section from the far end to the proximal end. The top of the lower support body 5 is cylindrical and the rear is hollow. The outer end of the piston 4 and the upper mold 1 of the synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com