Temperature control device of hot blast furnace

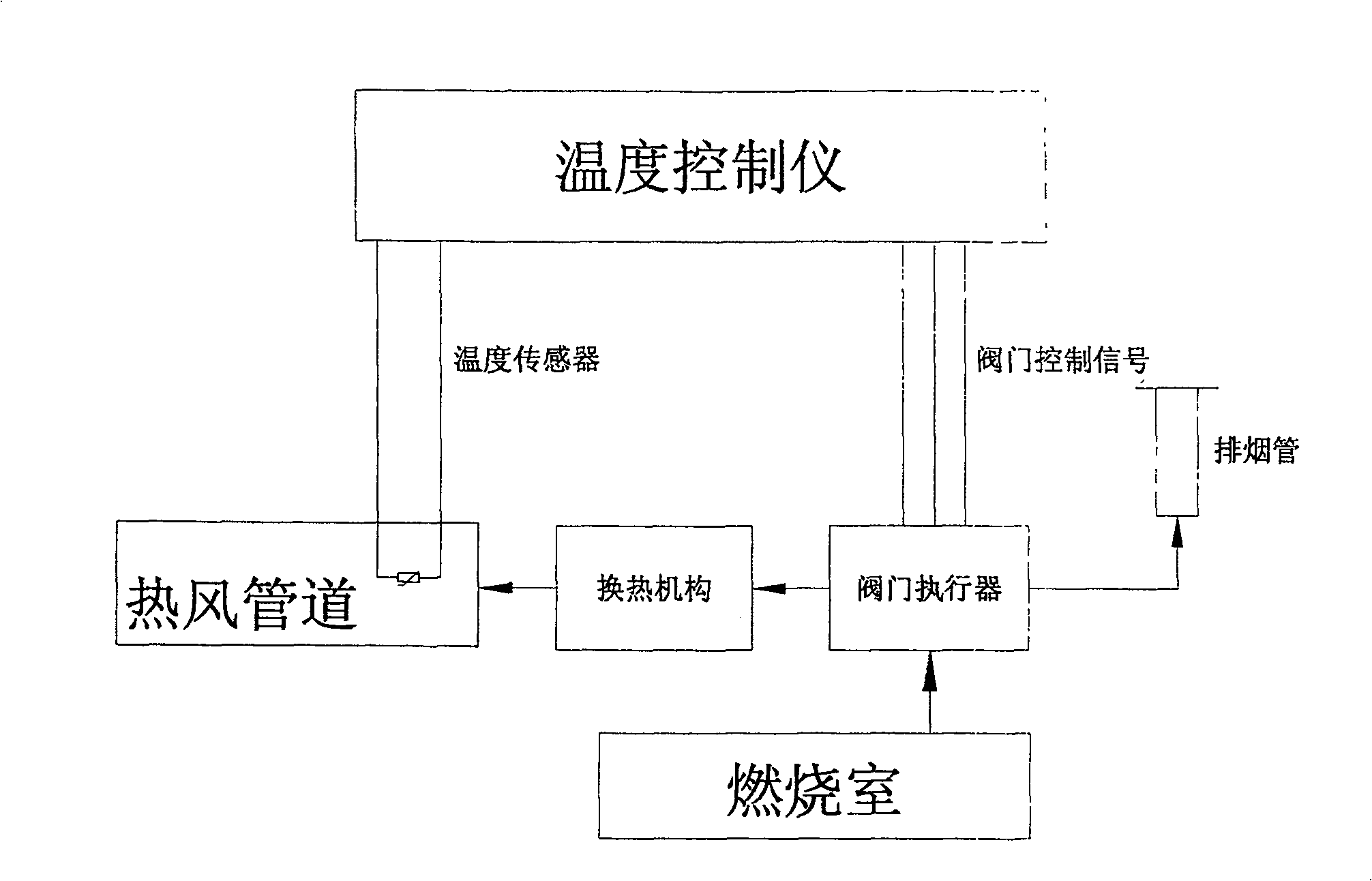

A temperature regulation, hot blast stove technology, applied in dryers, heating devices, lighting and heating equipment, etc., can solve the problems of reduced service life, large temperature fluctuations, large heat loss, etc., to achieve small changes in heat exchange characteristics, temperature Stable, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

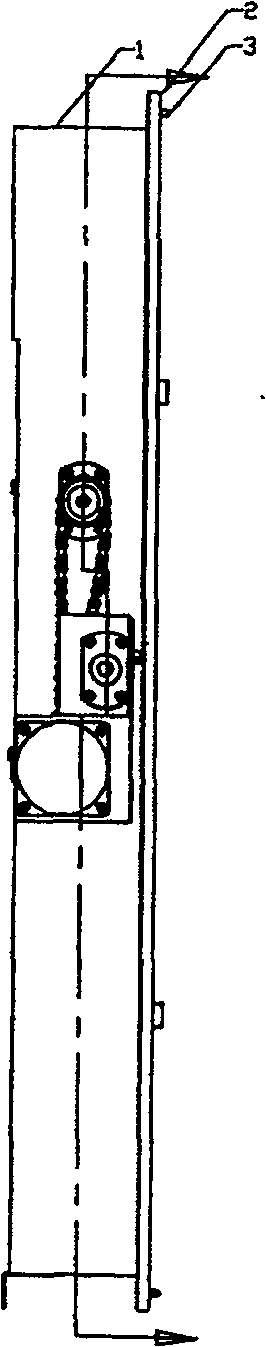

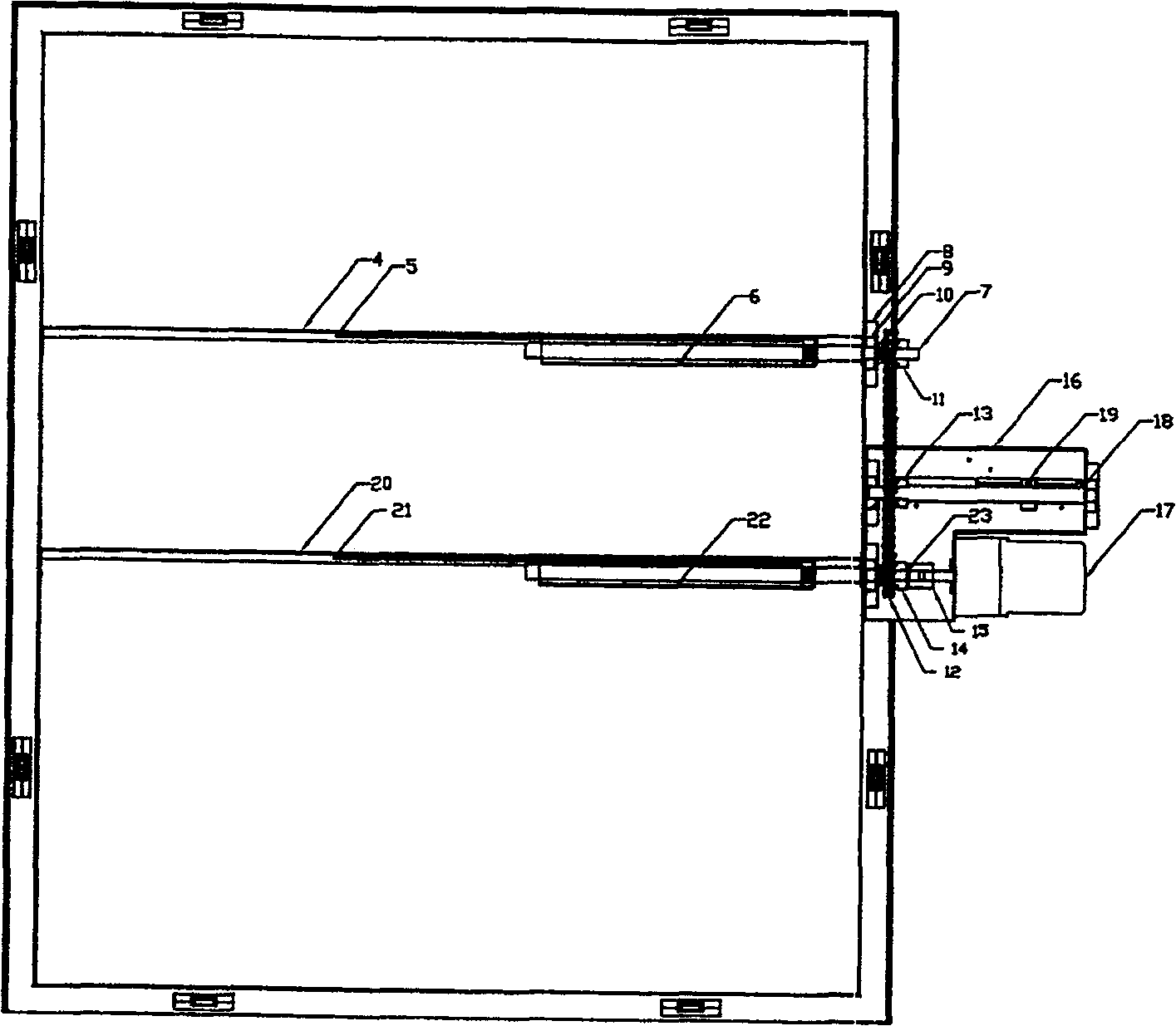

[0014] The present invention mainly consists of a base 1, a cover plate 2, a latch seat 3, a first valve base 4, a second valve base 20, a first valve guide groove 5, a second valve guide groove 21, a first valve plate 6, a second valve Plate 22, first valve actuator screw 7, second valve actuator screw 23, bearing seat 8, bearing 9, screw tightening nut 10, driven sprocket 11, valve actuator chain 12, valve position driven sprocket 13. Main transmission sprocket 14, shaft coupling 15, motor mounting plate 16, reduction motor 17, position transmission screw rod 18 and position transmission gear iron 19 etc. are composed.

[0015] Such as figure 1 , 2 As shown: the present invention mainly adopts the cover plate 2 to be installed on the base 1; two first and second valve bases 4, 20 are respectively installed on the base 1, and two first and second va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com