Multifunctional measuring tool

A multi-functional, measuring tool technology, applied in the field of measuring tools, can solve the problems of inconvenient and flexible use, uncommon use, high production cost, etc., and achieve the effects of convenient operation, simple production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

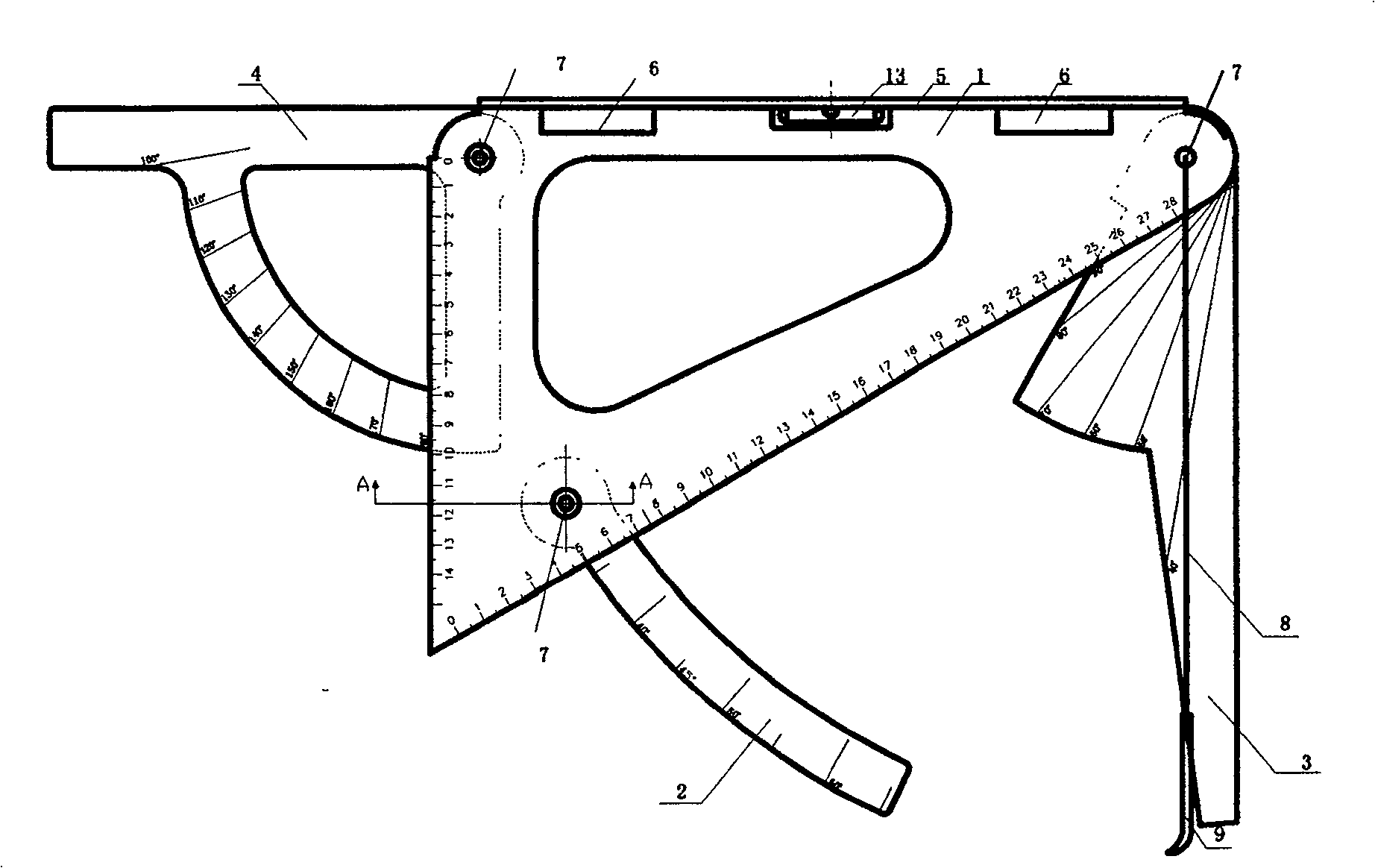

[0076] Example 1: Measurement of an angle of 60° to the horizontal plane,

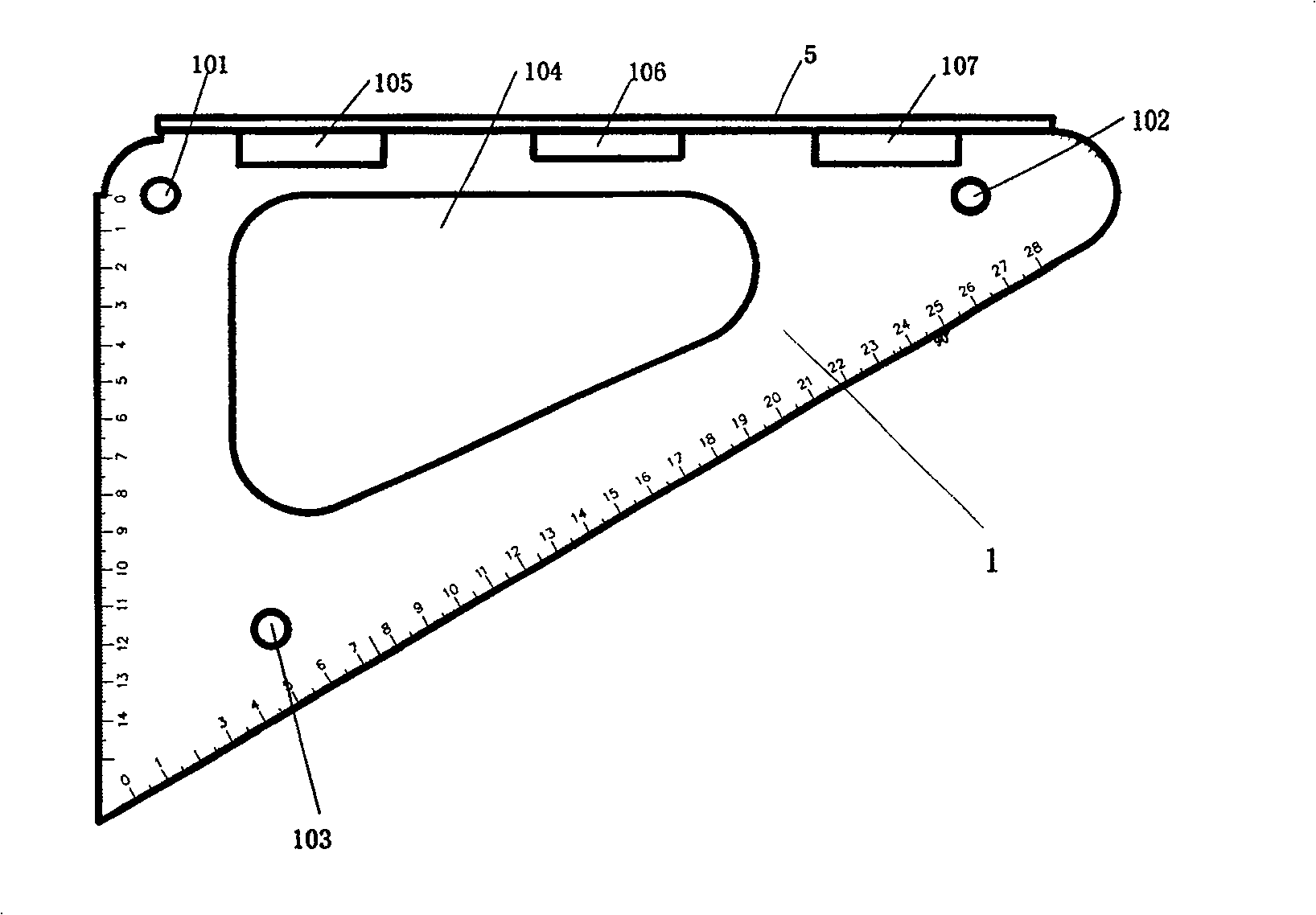

[0077] (1) Utilize the horizontal blister bead 13 arranged in the horizontal blister bead placement port 106 to find the horizontal position;

[0078] (2) Utilize the circular permanent magnet assembly block 6 inserted into the first permanent magnet insertion opening 105 and the second permanent magnet insertion opening 107 to be fixed on the base surface to draw an angle;

[0079] (3) Make the long right-angle side of the right-angled triangle scale panel 1 coincide with the 60 ° line of the embedded active angle plate 3;

[0080] (4) Draw a line along the extension arm 33 of the second triangular straight side to obtain the desired angle.

example 2

[0081] Example 2: Measurement of the angle at 120° to the horizontal plane,

[0082] (1) Utilize the horizontal blister bead 13 arranged in the horizontal blister bead placement port 106 to find the horizontal position;

[0083] (2) Utilize the circular permanent magnet assembly block 6 inserted into the first permanent magnet insertion opening 105 and the second permanent magnet insertion opening 107 to be fixed on the base surface to draw an angle;

[0084] (3) make the short straight side of the right-angled triangle scale panel 1 overlap with the 120 ° line of the embedded P-shaped angle plate 4;

[0085] (4) Draw a line along the extension arm 43 of the first triangular straight side to obtain the desired angle.

example 3

[0086] Example 3: Measurement of an angle of 55° with the vertical plane

[0087] (1) Utilize the hammer line 8 and the hanging hammer 9 to determine the vertical plane;

[0088] (2) Move the right-angled triangle scale panel 1 so that it coincides with the 55° angle of the embedded scale arm 2 with a partially arc-shaped strip;

[0089] (3) Utilize the circular permanent magnet combination block 6 inserted into the first permanent magnet insertion opening 105 and the second permanent magnet insertion opening 107 to be fixed on the base surface to draw an angle;

[0090] (4) Draw a line along the long right-angle side of the triangle right-angle scale panel 1 to obtain the required angle.

[0091] The multifunctional measuring tool installed by the components of the present invention has a wide range of uses, and will not be repeated in detail!

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com