Steam injection boiler with four return loop pipeline

A circulation pipeline and steam injection boiler technology, applied in steam boilers, forced flow steam boilers, steam generation, etc., can solve the problems of large volume, failure to reach 100 tons/hour, and large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

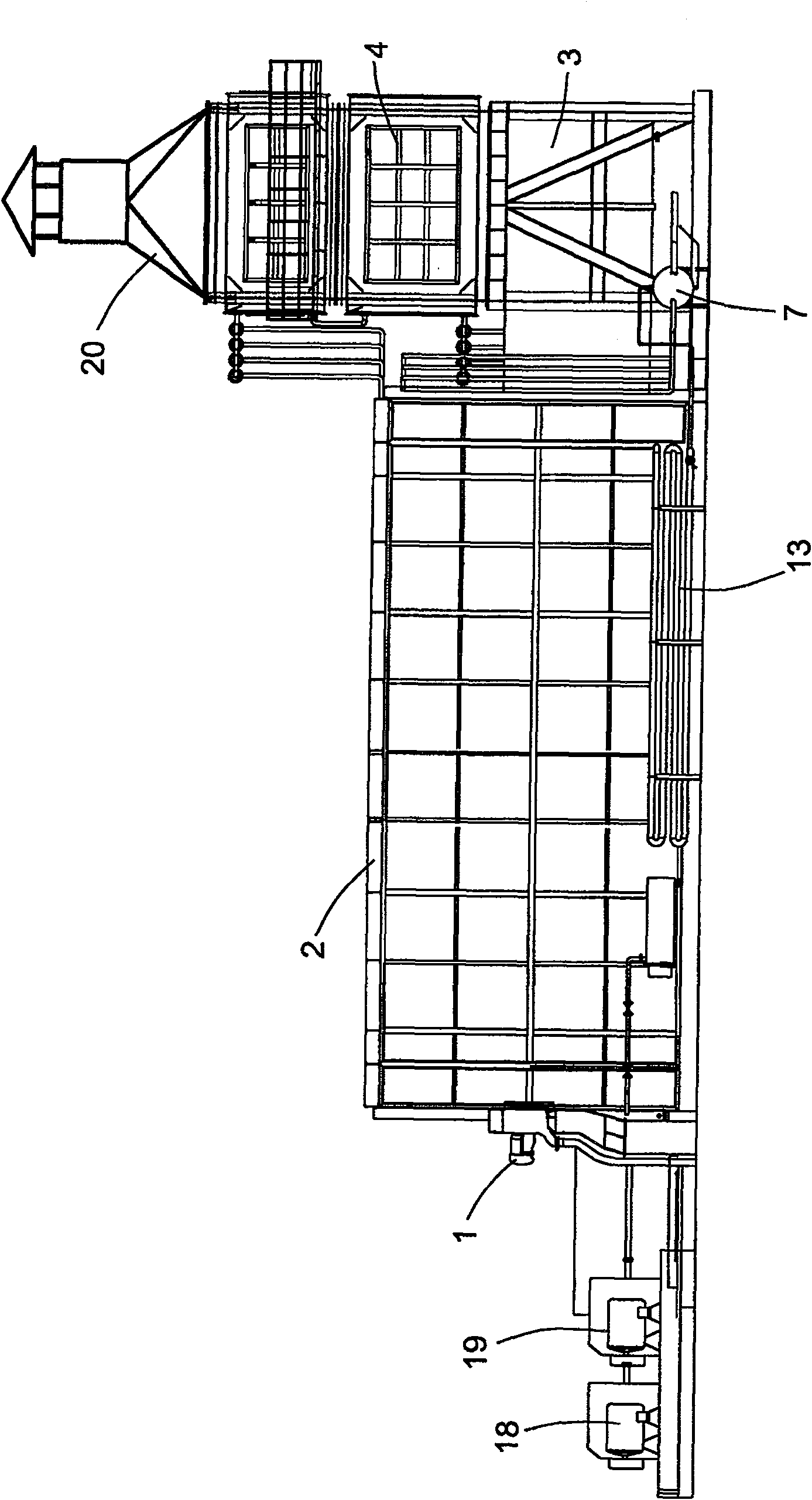

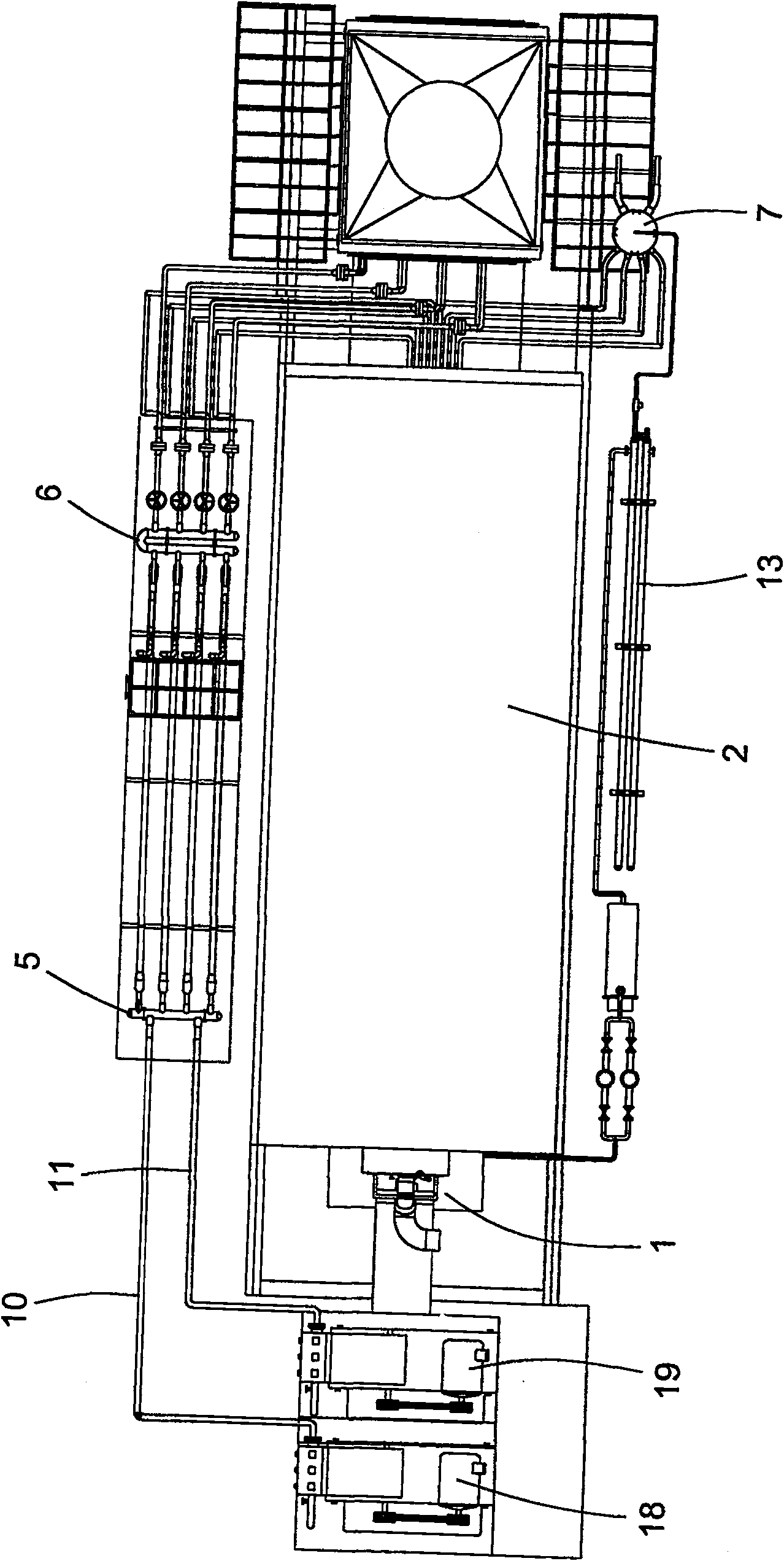

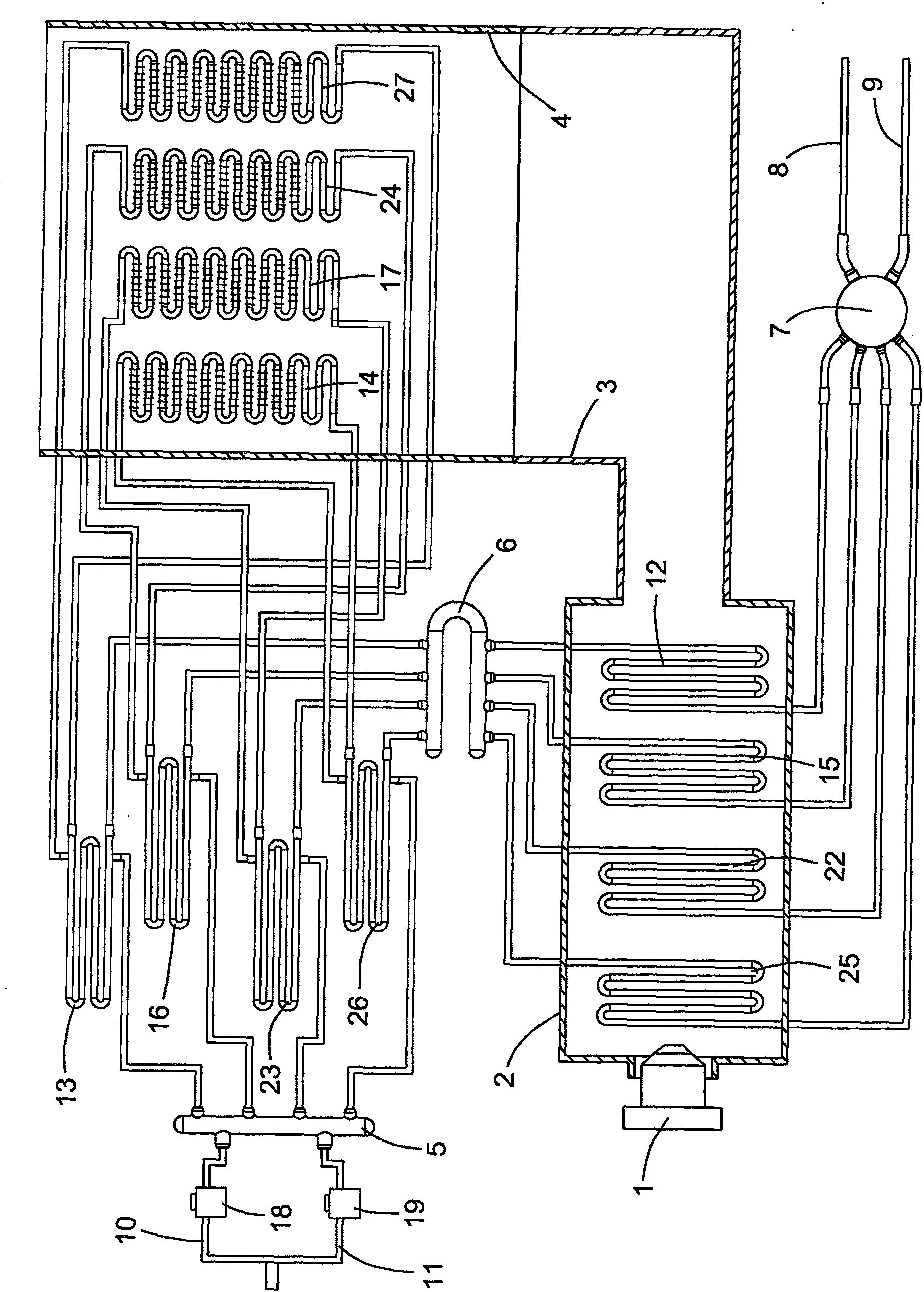

[0023] Label in the figure

[0024] 1 burner 2 radiant section 201 housing

[0025] 202 standard aluminum silicate refractory fiber 203 aluminum foil

[0026] 204 high alumina aluminum silicate refractory fiber 3 transition section 4 convection section

[0027] 5 distributor 501 water inlet 502 water inlet

[0028] 505 outlet 506 outlet 507 outlet

[0029] 508 water outlet 6 mixer

[0030] 601 water inlet 602 water inlet 603 water inlet 604 water inlet

[0031] 605 outlet 606 outlet 607 outlet 608 outlet

[0032] 7 steam collector 701 steam inlet 702 steam inlet

[0033] 703 steam inlet 704 steam inlet 705 steam outlet 706 steam outlet

[0034] 8 Steam discharge pipe 9 Steam discharge pipe 10 Water supply pipe

[0035] 11 Water supply pipe 12 Radiant tube bundle 13 Feed water heat exchanger

[0036] 14 Convection tube bundle 15 Radiant tube bundle 16 Feed water heat exchanger

[0037] 17 Convection tube bundle 18 High pressure plunger pump 19 High pressure plunger pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com