Light-emitting device and electronic apparatus

A technology for light-emitting devices and light-emitting elements, which can be applied to lighting devices, electric solid-state devices, electroluminescent light sources, etc., can solve problems such as inability to obtain sealing, cracking of organic EL elements, and deterioration of organic EL elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

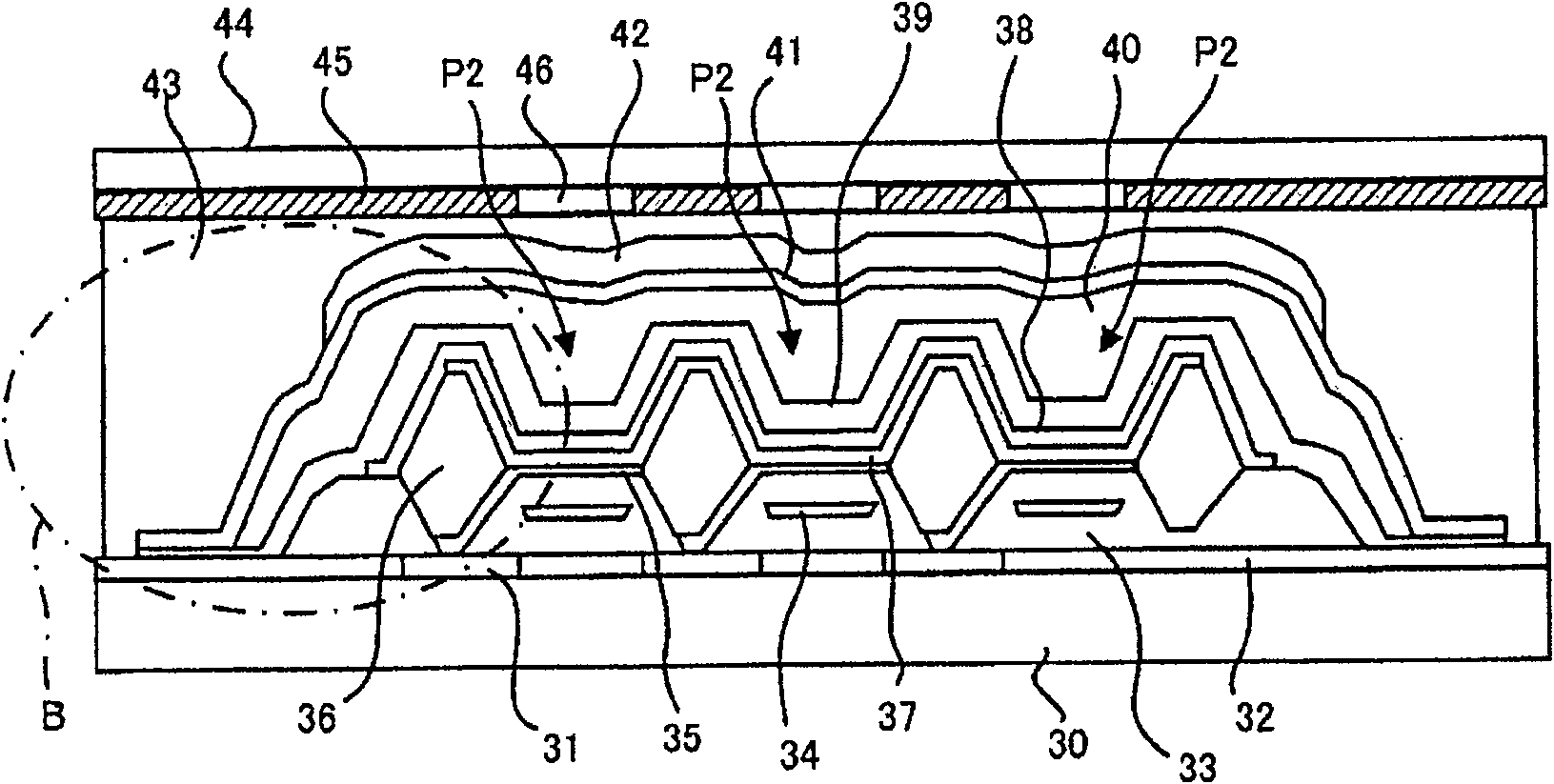

The organic EL panel according to the second embodiment of the present invention is a full-color panel using a low-molecular-weight organic EL material described later. This organic EL panel uses organic EL elements and color filters that emit white light. In addition, this organic EL element is of a top emission type in which light from the organic EL element is emitted from the side opposite to the main substrate.

[0042]

image 3 is a cross-sectional view of the organic EL panel, Figure 4 It is an enlarged cross-sectional view of the part B thereof. This organic EL panel includes a flat main substrate 30 . The main substrate 30 is formed of glass or plastic, and a plurality of organic EL elements P2 are formed thereon. The organic EL element P2 is an element that emits white light, and has an organic light-emitting layer 37 formed using a low-molecular-weight organic EL material described later. The inner luminescent layer) emits light.

[0043]

On the main su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com